Automatic technological parameter-optimizing injection molding machine control system and control method thereof

A technology of process parameter optimization and process parameter, which is applied in the injection molding machine control system and its control field, can solve the problems of easy occurrence of large deviations, and the determination of the process parameters of the injection molding machine cannot be very accurate and efficient, so as to reduce the number of trial injections The number of times, the effect of efficient determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

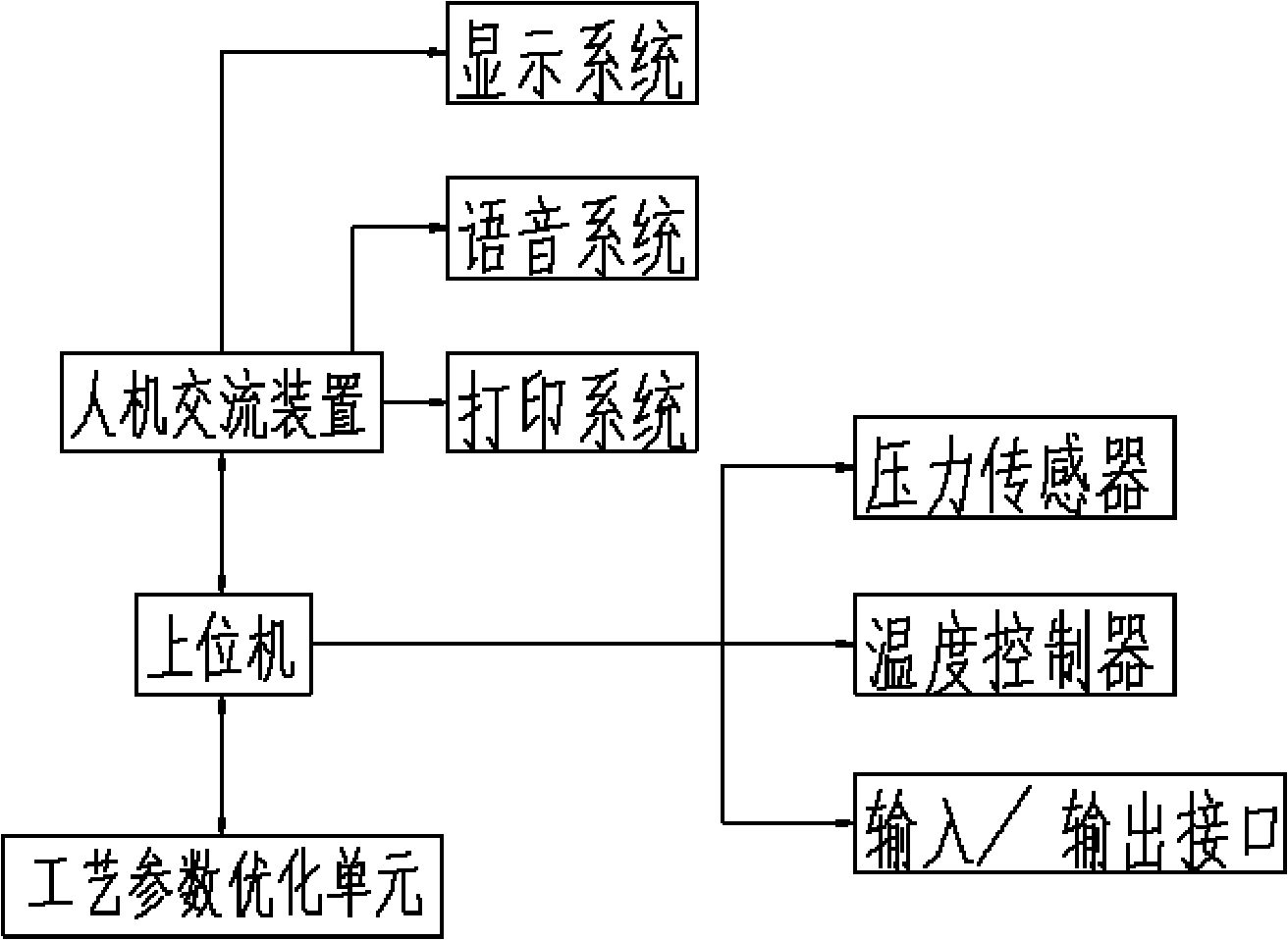

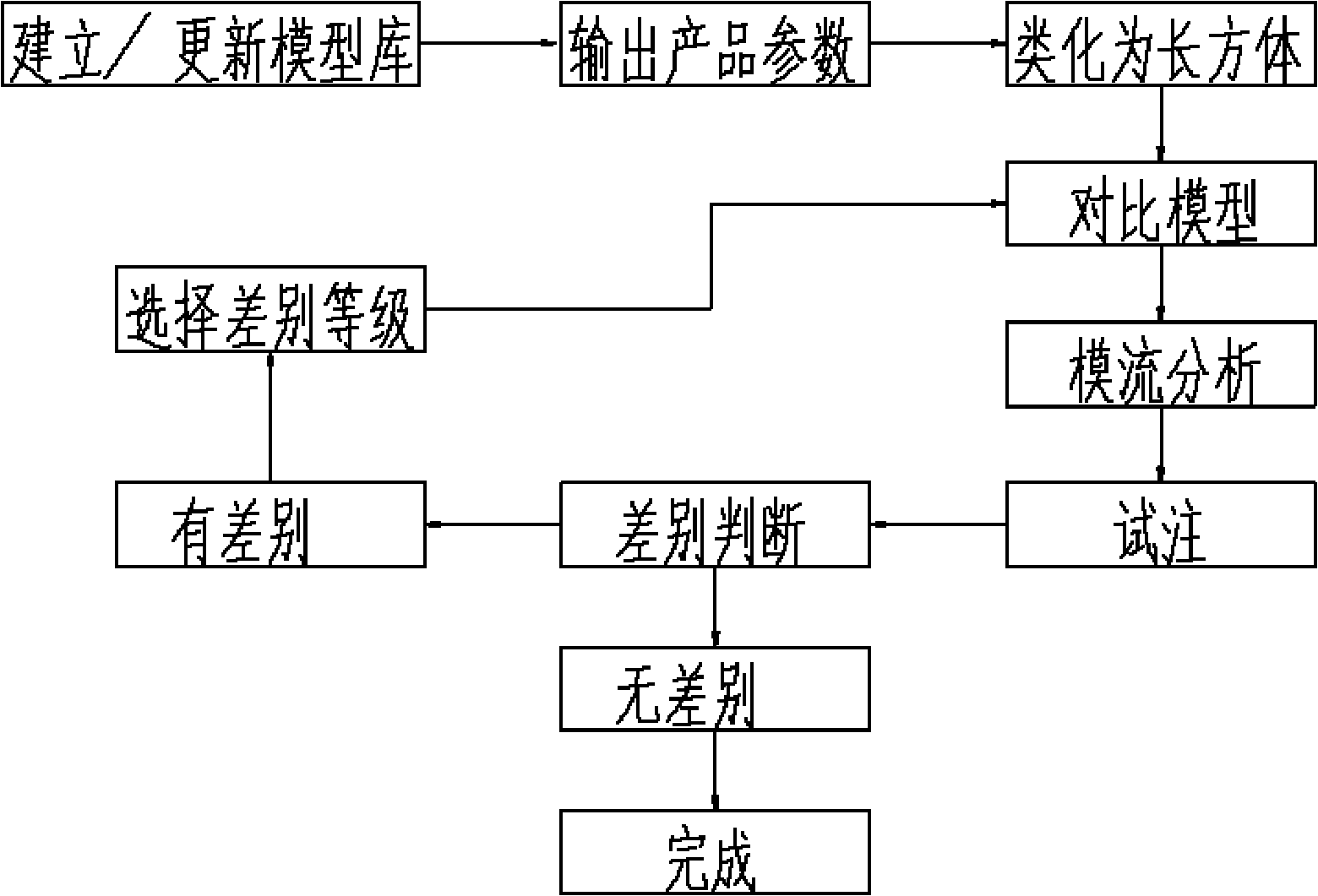

[0026] Example: as attached figure 1 As shown, the present invention is an injection molding machine control system for automatic optimization of process parameters, including a host computer and a man-machine communication device, and the host computer is respectively connected with a pressure sensor, a temperature controller, and an input / output interface. The human-machine communication device includes a display system, a voice system, a printing system, and an input device for the difference between samples and real products. The difference includes 5 levels, which are very small, small, medium, slightly large, and super large. A process parameter optimization unit is provided on the upper computer, and a model library is provided in the process parameter optimization unit. The content stored in the model library includes the product parameters and process parameters corresponding to the model. Product parameters include raw materials, shape, weight, and color of the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com