Method for full-scale characterization of pore throats of tight sandstone or shale oil reservoir

A technology for tight sandstone and shale oil, applied in the field of oil and gas development experiments, can solve the problems of large pore error, narrow effective range, and large scale span, and achieve the effect of reducing development cost and improving development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

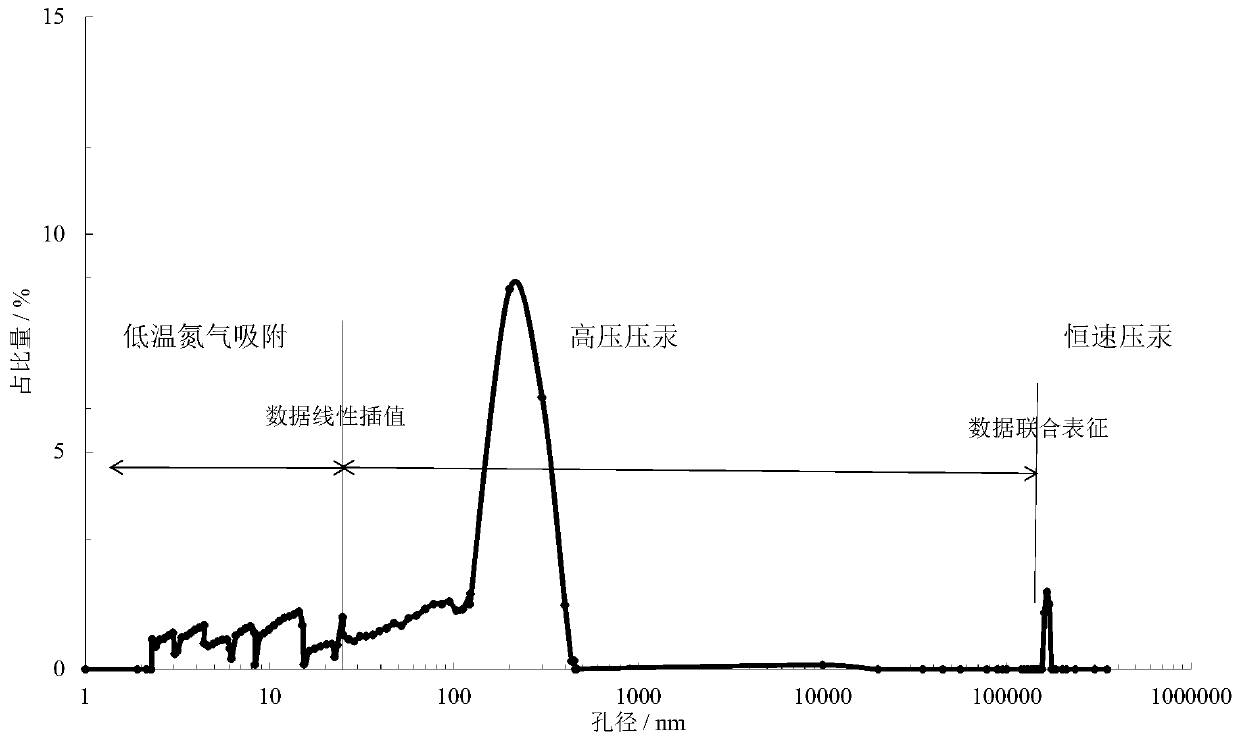

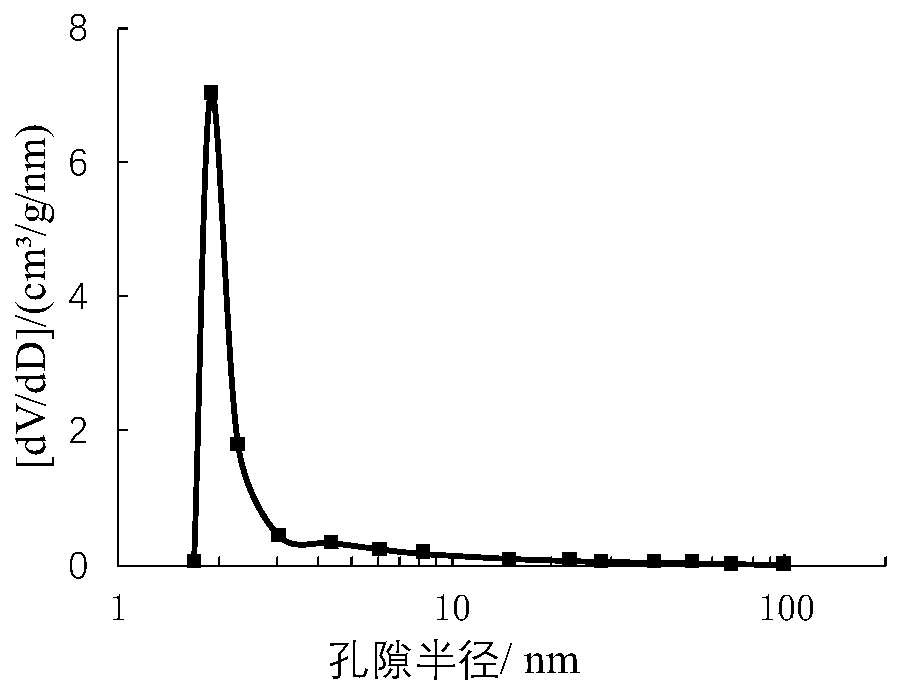

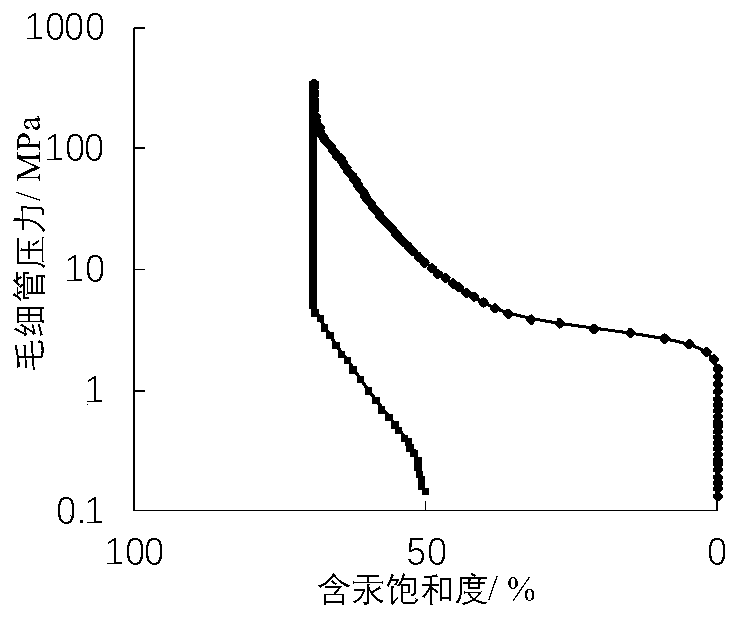

[0027] The present invention provides a method for full-scale characterization of pore throats in tight sandstone or shale oil reservoirs. Quantitative characterization of the microscopic pore structure characteristics of sandstone or shale oil reservoirs. According to the measurement accuracy range of different testing instruments, the pore throats with a radius of 2-25nm are characterized by linear interpolation of low-temperature nitrogen adsorption and high-pressure mercury injection test data. ; The pore throats with a radius greater than 25nm are jointly characterized by high-pressure mercury intrusion and constant-velocity mercury intrusion test data, so as to perform full-scale quantitative characterization of pore throats in tight sandstone or shale oil reservoirs, and make tight sandstone or shale oil Quantitative characterization map of full-scale distributi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com