Fault selecting method and apparatus

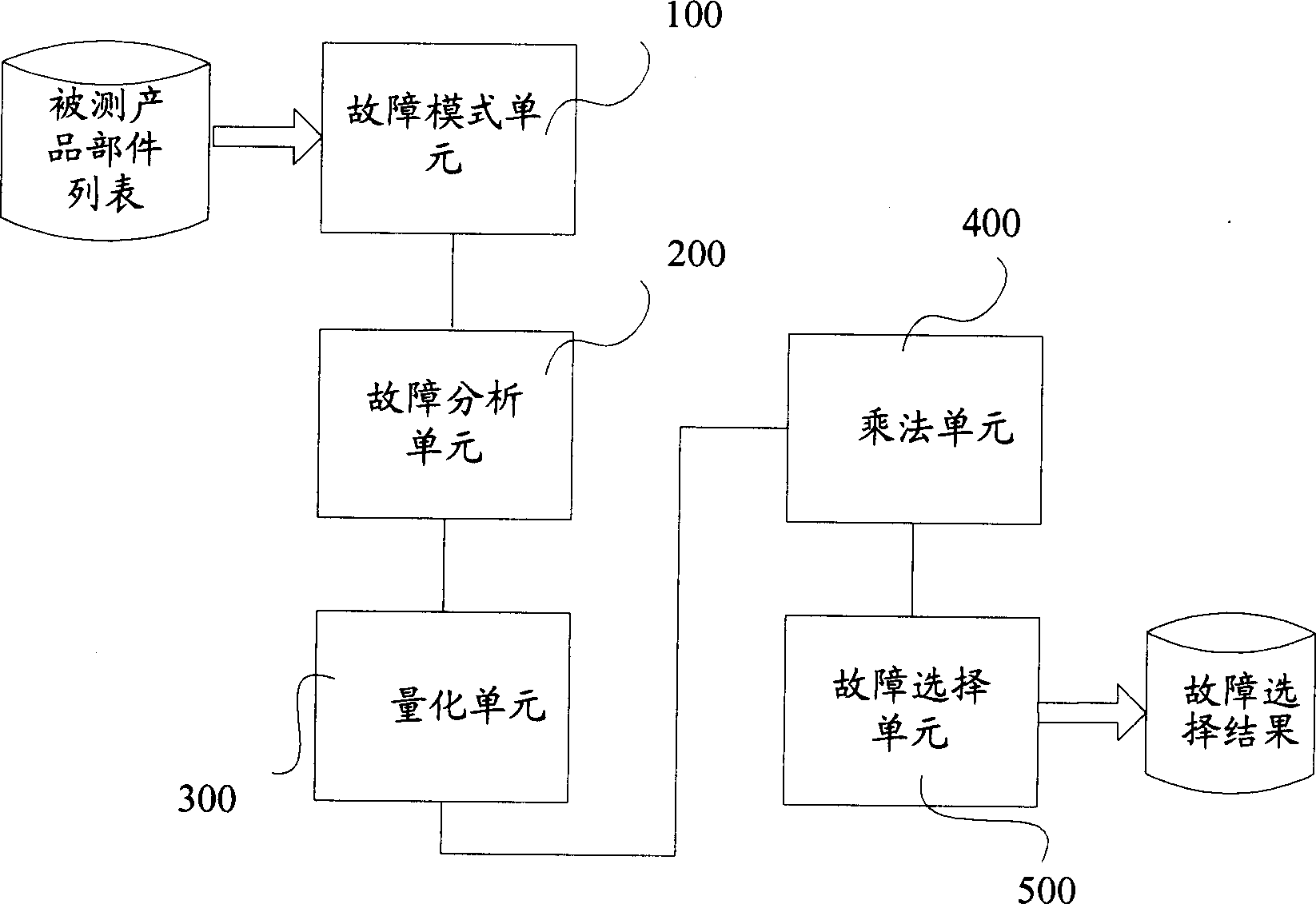

A technology for selecting devices and faults, which is applied in the field of fault selection methods and devices, can solve problems such as failure to comprehensively consider fault occurrence rate and fault impact, lack of universality of test results, and reduced reliability of test results, etc., to achieve the result of fault selection The effects of standardization, avoidance of manufacturing failure forms, and reasonable selection of failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

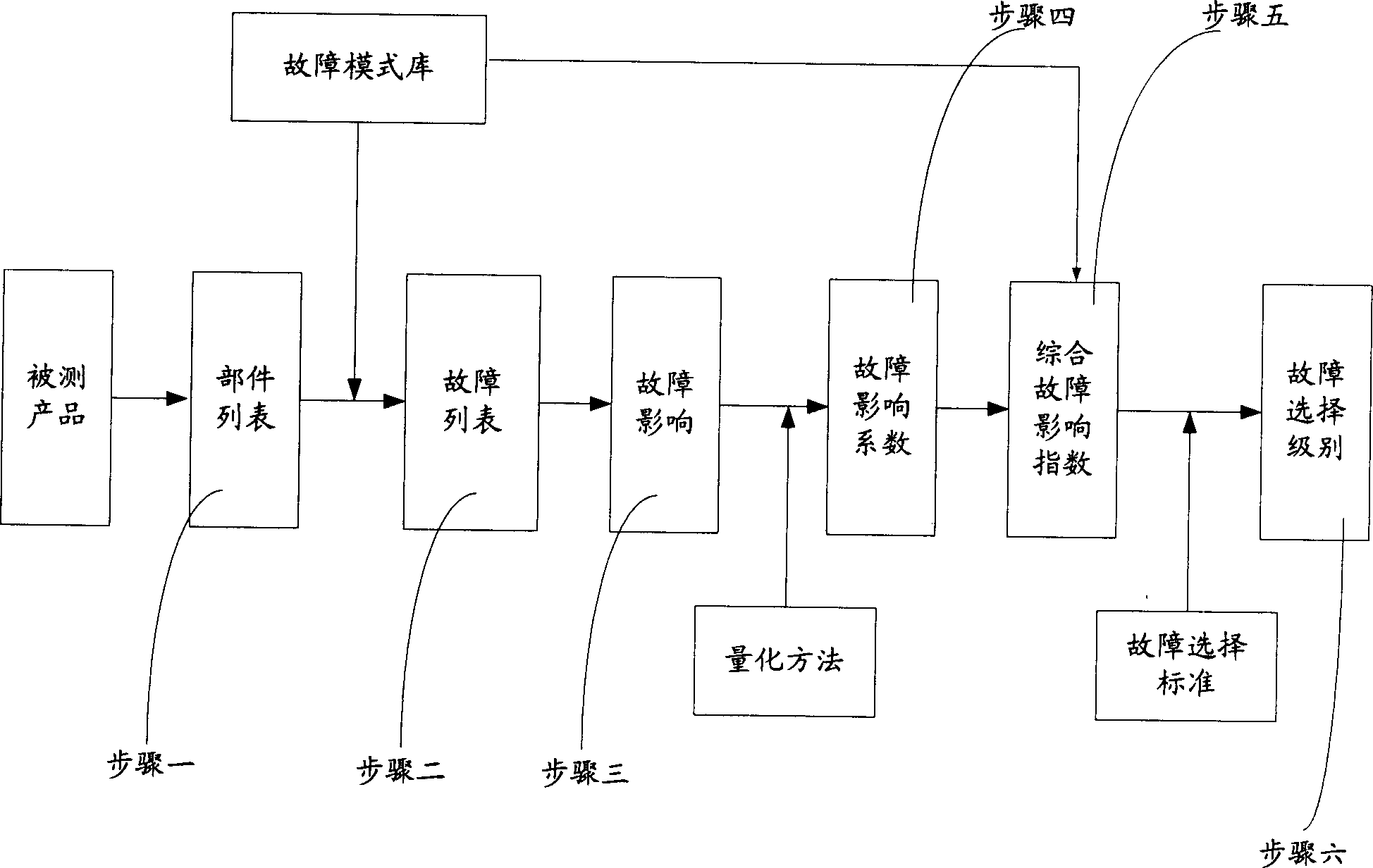

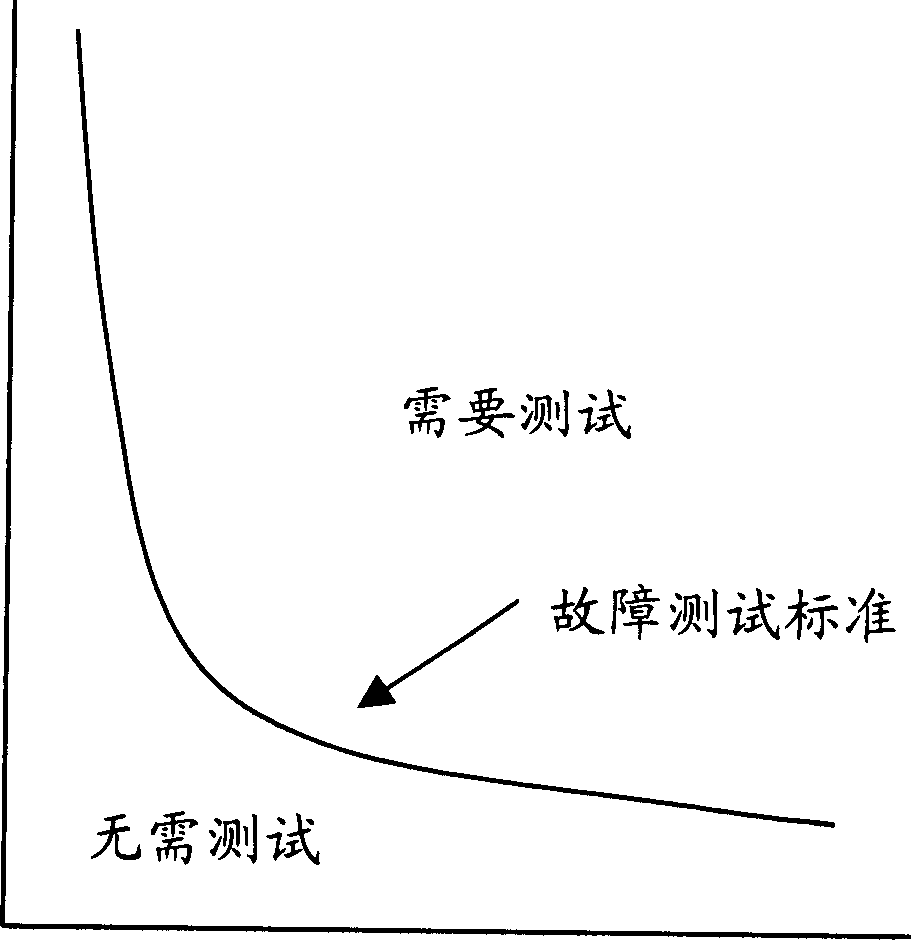

Method used

Image

Examples

no. 1 example

[0058] The first embodiment: in the failure analysis, the process of carrying out the parts list of the product under test and the parts list of the parts is as described above, and will not be repeated here. The damage degree of the tested product can usually be divided into four levels: fatal, serious, general, and warning. The specific meanings of the four levels are as follows:

[0059] Fatal - cause the whole machine to be paralyzed.

[0060] Severe—Loss of major functionality or severely degraded performance that will take longer to recover.

[0061] Fair—loss of minor function or slight decline in performance, with quick recovery.

[0062] Reminder—basically does not affect the function and performance, and it can be maintained afterwards.

[0063] The fault level division standard is clear, which can ensure that the analysis results of different testers on the impact of faults are basically consistent, so as to guide fault selection and ensure the consistency of test...

no. 2 example

[0074] The second embodiment: the process of performing component listing of the product under test and performing component listing of the components in the failure analysis is as described above, and will not be repeated here. The division of the failure impact level in the failure analysis process can also be based on the failure For the quantification of the economic loss caused by the tested product, the economic loss caused by the loss of system function and performance degradation caused by the internal failure of the switch is taken as an example to illustrate the quantification method.

[0075] Some failures of switch components (such as: signal transmission quality degradation, clock jitter) will lead to a decrease in call quality, occasional noise during user calls, and user complaints will lead to telecom operators starting maintenance projects. Assuming that the general maintenance cost is 1,000 yuan, the impact of this type of failure can be quantified as 1,000 yu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com