Controllable doping method for Si3N4 single-crystal low-dimension nano material

A low-dimensional nano- and single-crystal technology, applied in polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problems of inability to control the doping amount and limited doping amount of low-dimensional nano-materials, and achieve low cost , high repeatability, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

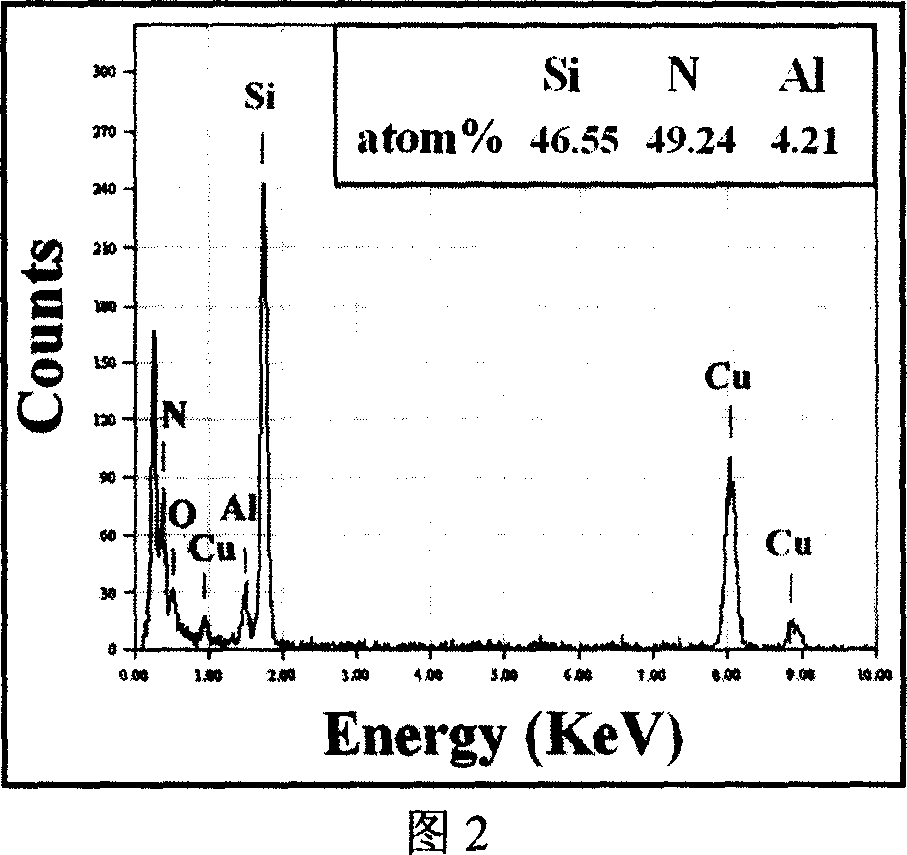

Embodiment 1

[0037] Weigh 10 g of the initial raw materials polysilazane and aluminum isopropoxide at a weight ratio of 4:1, put them into a nylon resin ball mill pot for planetary ball milling for 12 hours, and place them in a 99 alumina ceramic crucible after mixing evenly. N of MPa 2 Under the gas protection atmosphere, the temperature was raised from room temperature to 260°C at 10°C / min in a tubular sintering furnace, and kept for 0.5 hours for cross-linking and solidification to obtain an amorphous SiAlCN solid. Put the SiAlCN solid into a nylon resin ball mill jar, add 3wt% FeCl 2 The powder is used as a catalyst in a high-energy ball mill for dry ball milling for 24 hours, and then the SiAlCN powder obtained after the high-energy ball milling is placed in a 99 alumina ceramic crucible, and the flow (200ml / min) of N at 0.1MPa 2Under the protection of gas atmosphere, the temperature was increased from room temperature to 1300 °C in a tube furnace at 10 °C / min for high-temperature py...

Embodiment 2

[0039] Weigh 10 g of the initial raw materials polysilazane and aluminum isopropoxide at a weight ratio of 8:1, put them into a nylon resin ball mill jar for planetary ball milling for 12 hours, mix them uniformly and place them in a 99 alumina ceramic crucible, and place them in a 0.1 N of MPa 2 Under the gas protection atmosphere, the temperature was raised from room temperature to 260°C at 10°C / min in a tubular sintering furnace, and kept for 0.5 hours for cross-linking and solidification to obtain an amorphous SiAlCN solid. Put the SiAlCN solid into a nylon resin ball mill jar, add 3wt% FeCl 2 The powder is used as a catalyst in a high-energy ball mill for dry ball milling for 24 hours, and then the SiAlCN powder obtained after the high-energy ball milling is placed in a 99 alumina ceramic crucible, and the flow (200ml / min) of N at 0.1MPa 2 Under the protection of gas atmosphere, the temperature was increased from room temperature to 1300 °C in a tube furnace at 10 °C / min...

Embodiment 3

[0041] Weigh 10 g of the initial raw materials polysilazane and aluminum isopropoxide at a weight ratio of 16:1, put them into a nylon resin ball mill pot for planetary ball milling for 12 hours, mix them uniformly and place them in a 99 alumina ceramic crucible, and place them in a 0.1 N of MPa 2 Under the gas protection atmosphere, the temperature was raised from room temperature to 260°C at 10°C / min in a tubular sintering furnace, and kept for 0.5 hours for cross-linking and solidification to obtain an amorphous SiAlCN solid. Put the SiAlCN solid into a nylon resin ball mill jar, add 3wt% FeCl 2 The powder is used as a catalyst in a high-energy ball mill for dry ball milling for 24 hours, and then the SiAlCN powder obtained after the high-energy ball milling is placed in a 99 alumina ceramic crucible, and the flow (200ml / min) of N at 0.1MPa 2 Under the protection of gas atmosphere, the temperature was increased from room temperature to 1300 °C in a tube furnace at 10 °C / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com