A method for uniform doping of sic single crystal metal impurities

A uniform doping, single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of uneven release process, and achieve the effect of high repeatability and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for uniform doping of SiC single crystal metal impurities, comprising steps as follows:

[0036] (1) The high-purity SiC powder and the material to be doped are uniformly mixed, the mixing method includes ball milling or stirring, and the solid solubility of the material to be doped in SiC is used as the maximum doping value of the material to be doped; The material to be doped is one or more of metal, oxide, carbide or silicide, so as not to introduce other impurities.

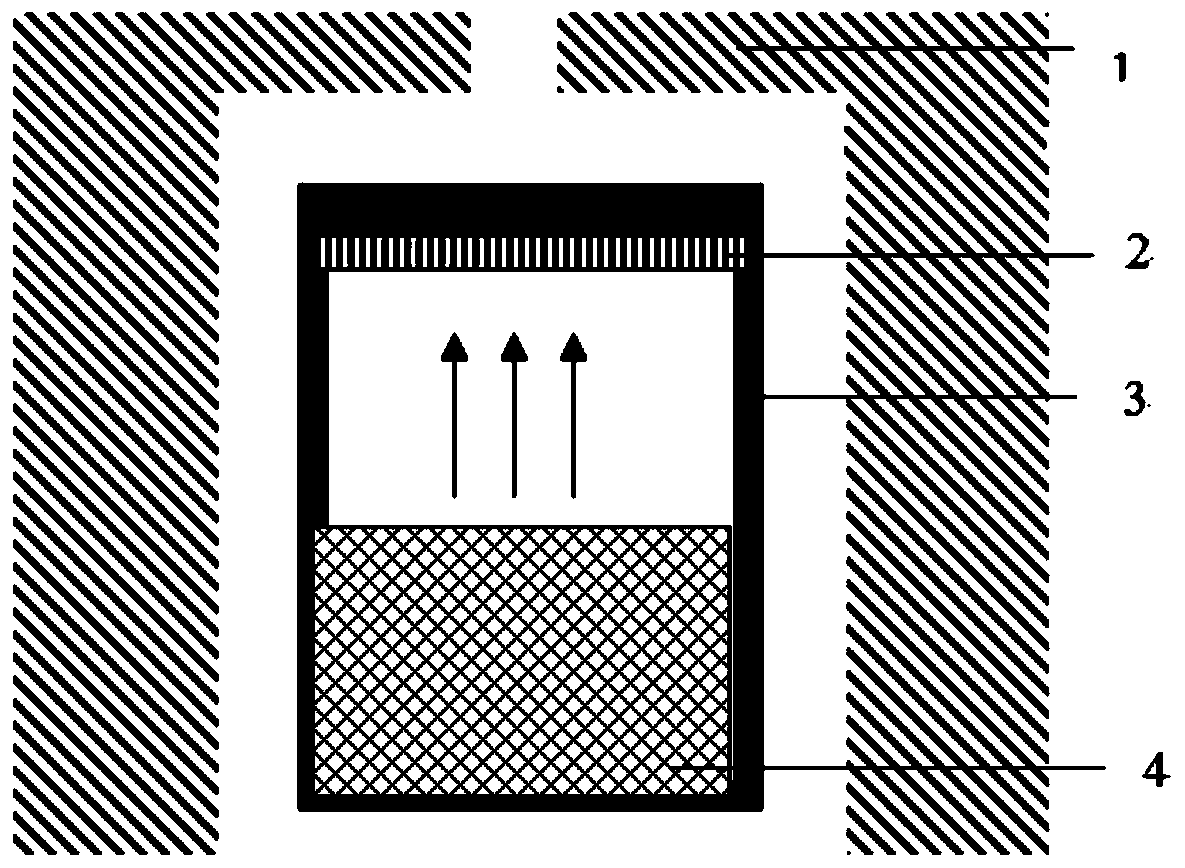

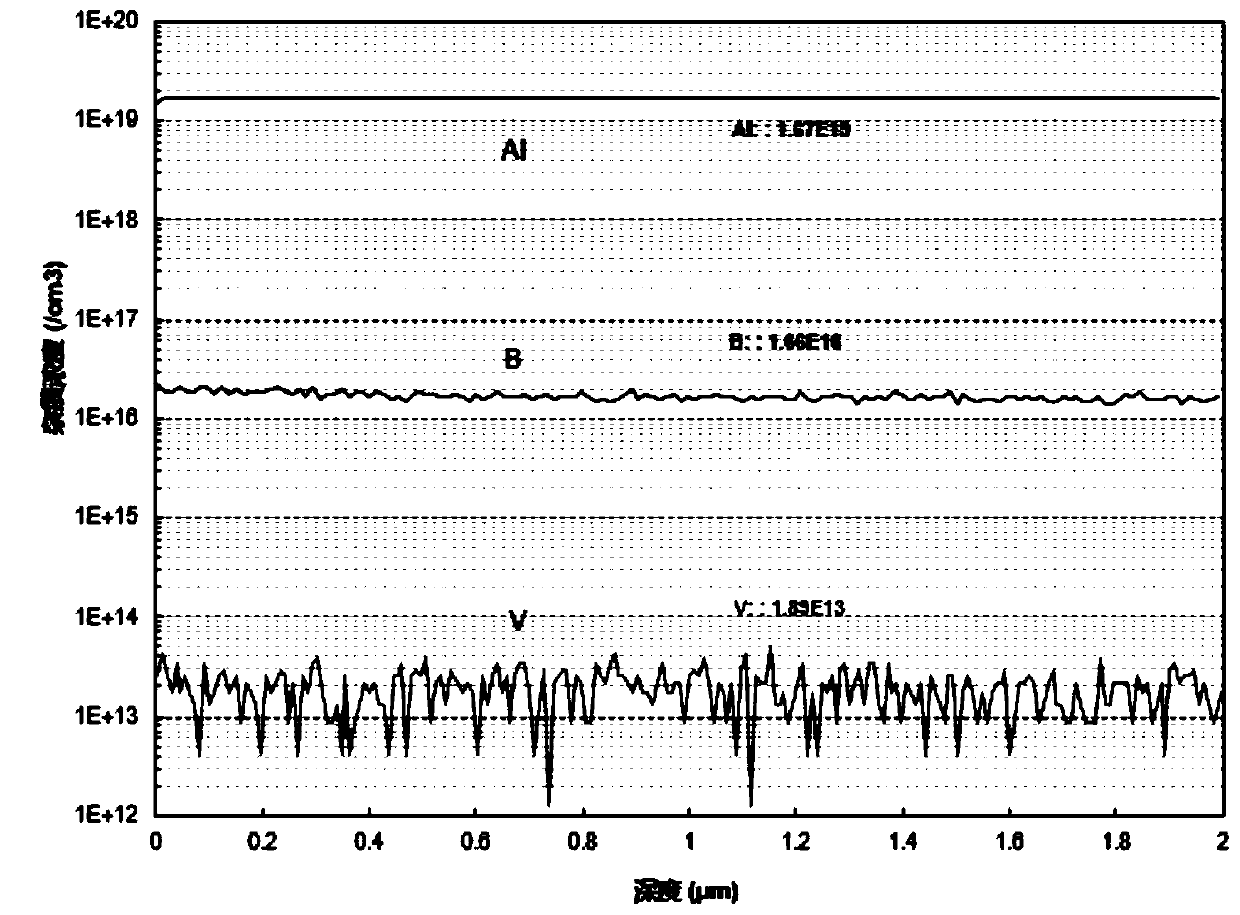

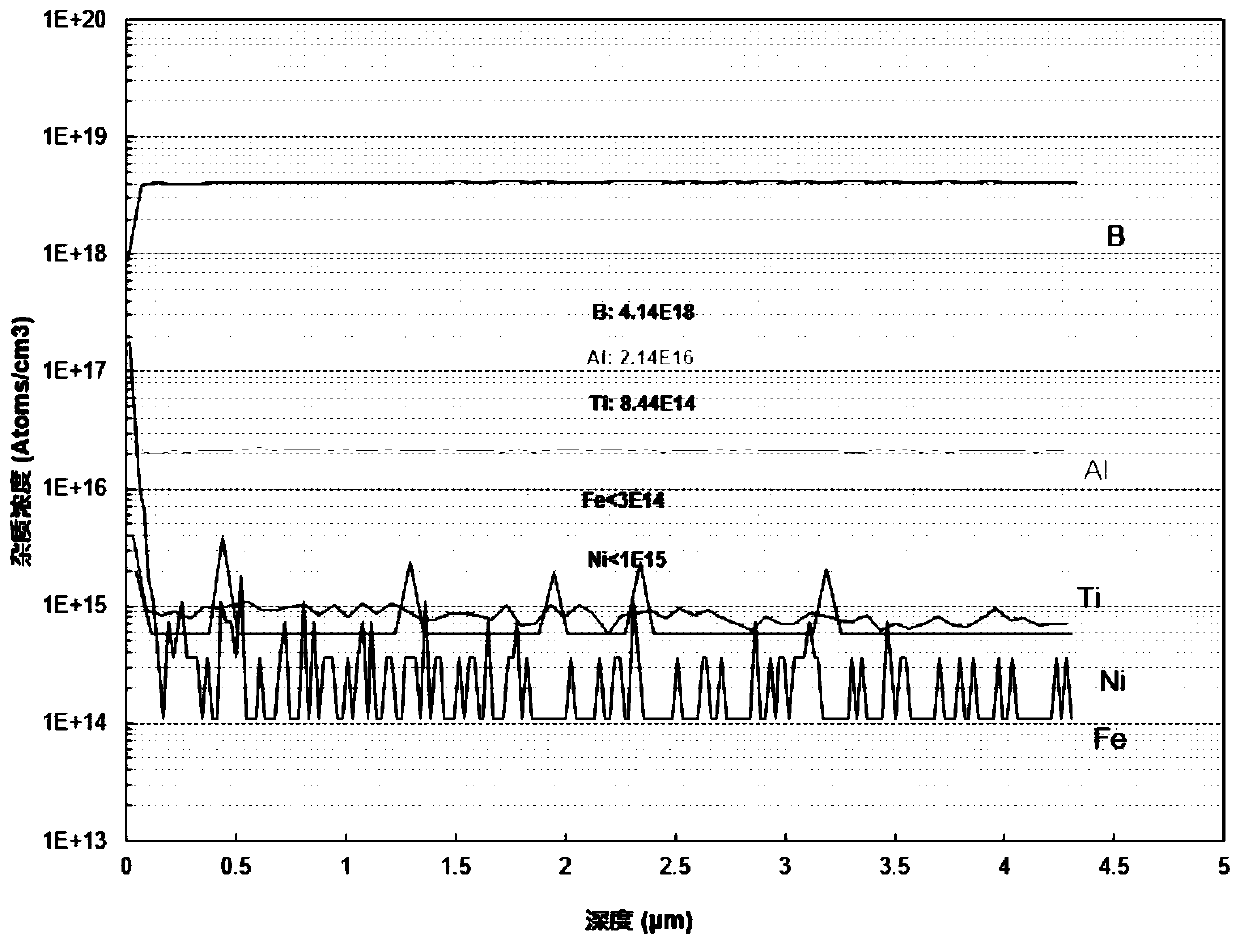

[0037] (2) After mixing, fill the high-purity sealed graphite crucible with the mixed powder, put it into a heating device with a temperature up to 2000°, and place it in a constant temperature zone; after closing the heating device, remove the growth after repeated pumping The remaining air in the cavity, especially the nitrogen and oxygen in the air, is fed with an inert gas such as argon as a background gas, and the pressure is maintained at normal pressure. Then heat up to 1800°C for 10 m...

Embodiment 2

[0041] A method for uniform doping of SiC single crystal metal impurities, the steps of which are as described in Example 1, the difference is that in step (2), after argon gas is introduced, the temperature is raised to 2500° C., and the heating time is 48 hours.

Embodiment 3

[0043] A method for uniform doping of SiC single crystal metal impurities, the steps of which are as described in Example 1, the difference is that in step (2), after heating up, keep warm for 48 hours and then cool down to normal temperature, the cooling rate is 50°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com