SiOC porous ceramics-loaded La0.9Sr0.1CoO3 nano particle catalyst prepared by fibre template method

A technology of porous ceramics and nanoparticles, applied in the direction of physical/chemical process catalysts, dispersed particle separation, separation methods, etc., can solve problems such as health hazards and difficult disposal of diesel engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take by weighing 0.9743 gram of lanthanum nitrate (La(NO 3 )·6H 2 O), 0.0529 grams of strontium nitrate (Sr(NO 3 ) 2 ) and 0.6227 g of cobalt acetate (Co(CH 3 COO) 2 4H 2 O) Dissolve in 7.3ml of deionized water, place it on a magnetic heating stirrer and stir, after the inorganic salts are completely dissolved, gradually add 7.5896 grams of polyvinylpyrrolidone (PVP), stir with a glass rod to make it fully mixed, at this time There are a lot of air bubbles in the spinnable sol, so it needs to stand for 24 hours.

[0036] The spinnable sol obtained is transferred to the syringe for electrospinning. The receiving pole plate is an aluminum plate wrapped with a layer of tinfoil. The voltage during spinning is 24KV, and the distance between the nozzle and the receiving pole plate is 20cm. The propulsion rate of the sol 0.9ml / h, the nozzle used is a stainless steel 8# needle (the needle needs to be ground flat, the nozzle needle can be purchased from the market with 6~9...

Embodiment 2

[0039] Take by weighing 0.9743 gram of lanthanum nitrate (La(NO 3 )·6H 2 O), 0.0529 grams of strontium nitrate (Sr(NO 3 ) 2 ) and 0.6227 g of cobalt acetate (Co(CH 3 COO) 2 ﹒ 4H 2 O) Dissolve in 7.3ml of deionized water, place it on a magnetic heating stirrer and stir, after the inorganic salts are completely dissolved, gradually add 7.5896 grams of polyvinylpyrrolidone (PVP), stir with a glass rod to make it fully mixed, at this time There are a lot of air bubbles in the spinnable sol, so it needs to stand for 24 hours.

[0040] The obtained spinnable sol is transferred to a syringe for electrospinning. The receiving plate is an aluminum plate wrapped with a layer of tinfoil. The voltage during spinning is 24KV, and the distance between the nozzle and the receiving plate is 20cm. The advancement of the sol The rate is 0.9ml / h, and the nozzle used is a stainless steel 8# needle (the needle needs to be ground flat). After 2~3 hours, it can be observed that a layer of fib...

Embodiment 3

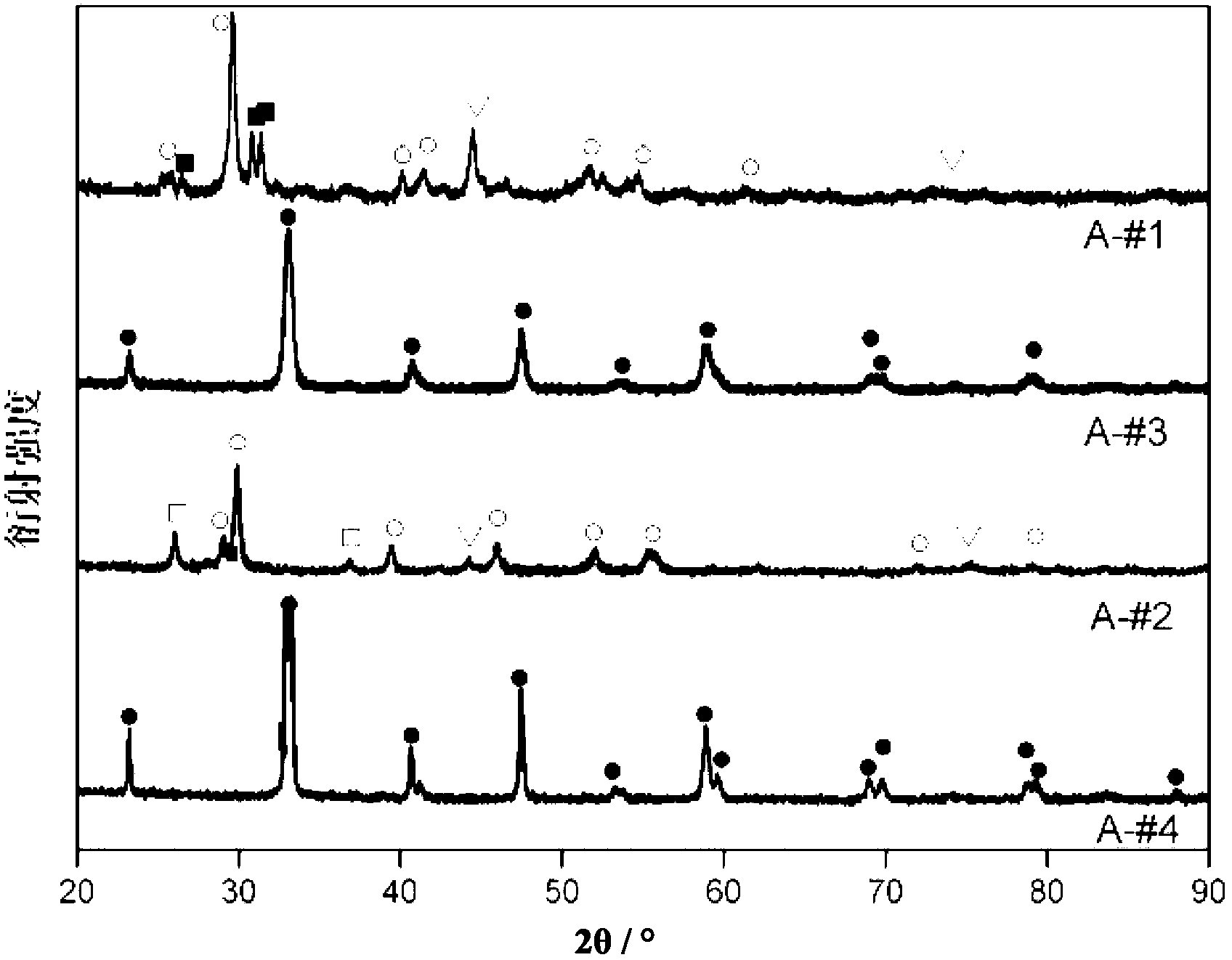

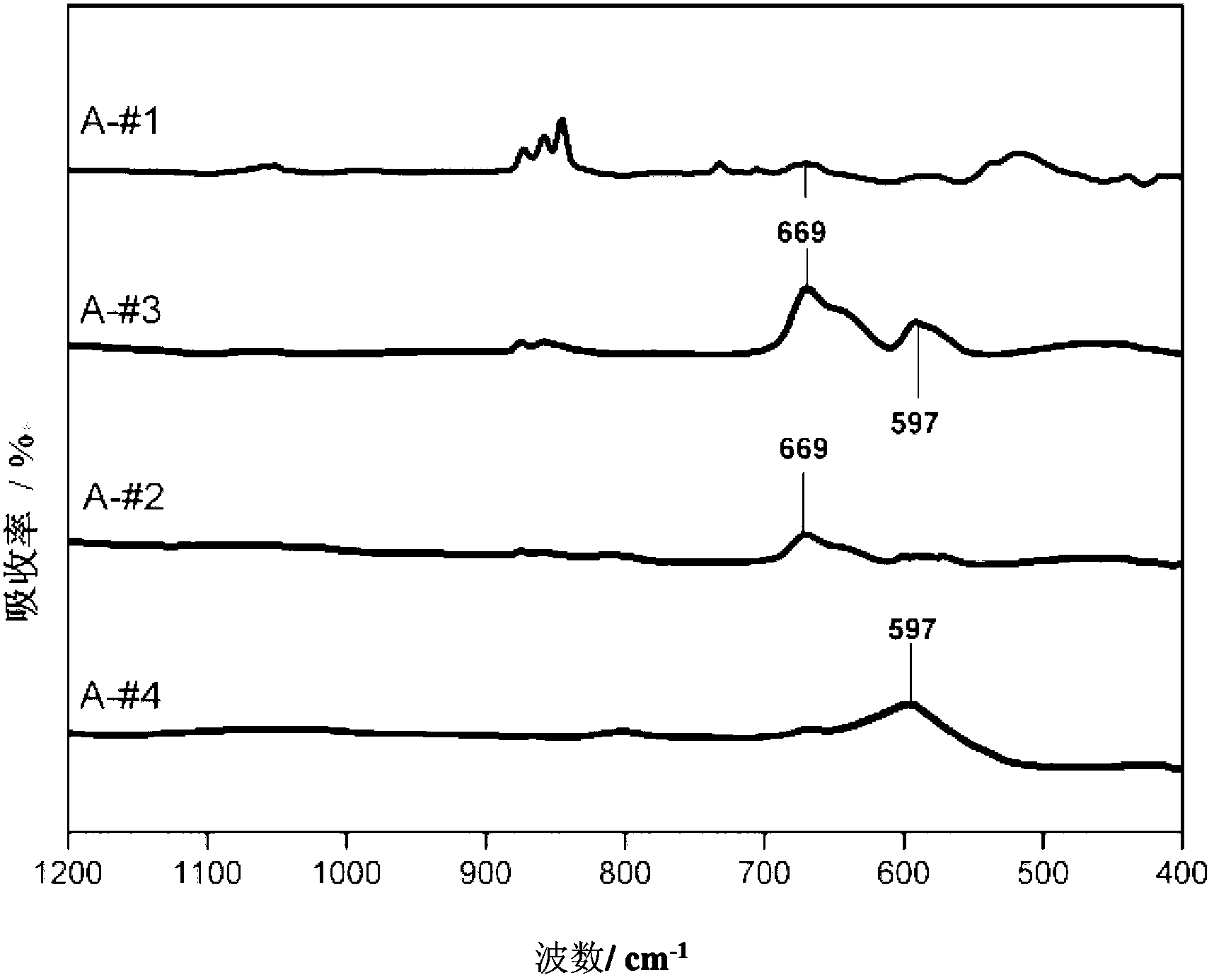

[0043] La in this example 0.9 Sr 0.1 CoO 3 Spinnable Sol and La 0.9 Sr 0.1 CoO 3 The preparation of the gel fiber is the same as in Example 1. The difference is: weigh hydrogen-containing polysiloxane (PHMS) and 1,3,5,7-tetramethyl-1,3,5,7-tetravinylcyclotetrasiloxane (D 4 Vi) Put 1g of each in an 8ml beaker, and vibrate for 1h to make the two fully mixed, drop a drop of methylvinylsiloxane-coordinated platinum catalyst with a mass fraction of 1% into the beaker, continue ultrasonic vibration for 1h, and obtain SiOC Precursor sol.

[0044] Weigh 0.05g of La 0.9 Sr 0.1 CoO 3 The gel fiber was placed in the prepared SiOC precursor sol, and ultrasonically vibrated for 1 hour to make it fully mixed. After it was solidified, it was taken out and placed in an electric blast drying oven, and heated at 35°C, 50°C, 60°C, and 70°C respectively. and 80°C for 4 hours each, and after cooling, a cross-linked body was obtained. Pyrolyze the obtained cross-linked body under flowing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com