VCV vertical U type cross-linking polyethylene insulation cable production line

A cross-linked polyethylene, insulated cable technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of no stress relaxation, impact, insulation deformation, etc., and achieve the effect of excellent insulation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

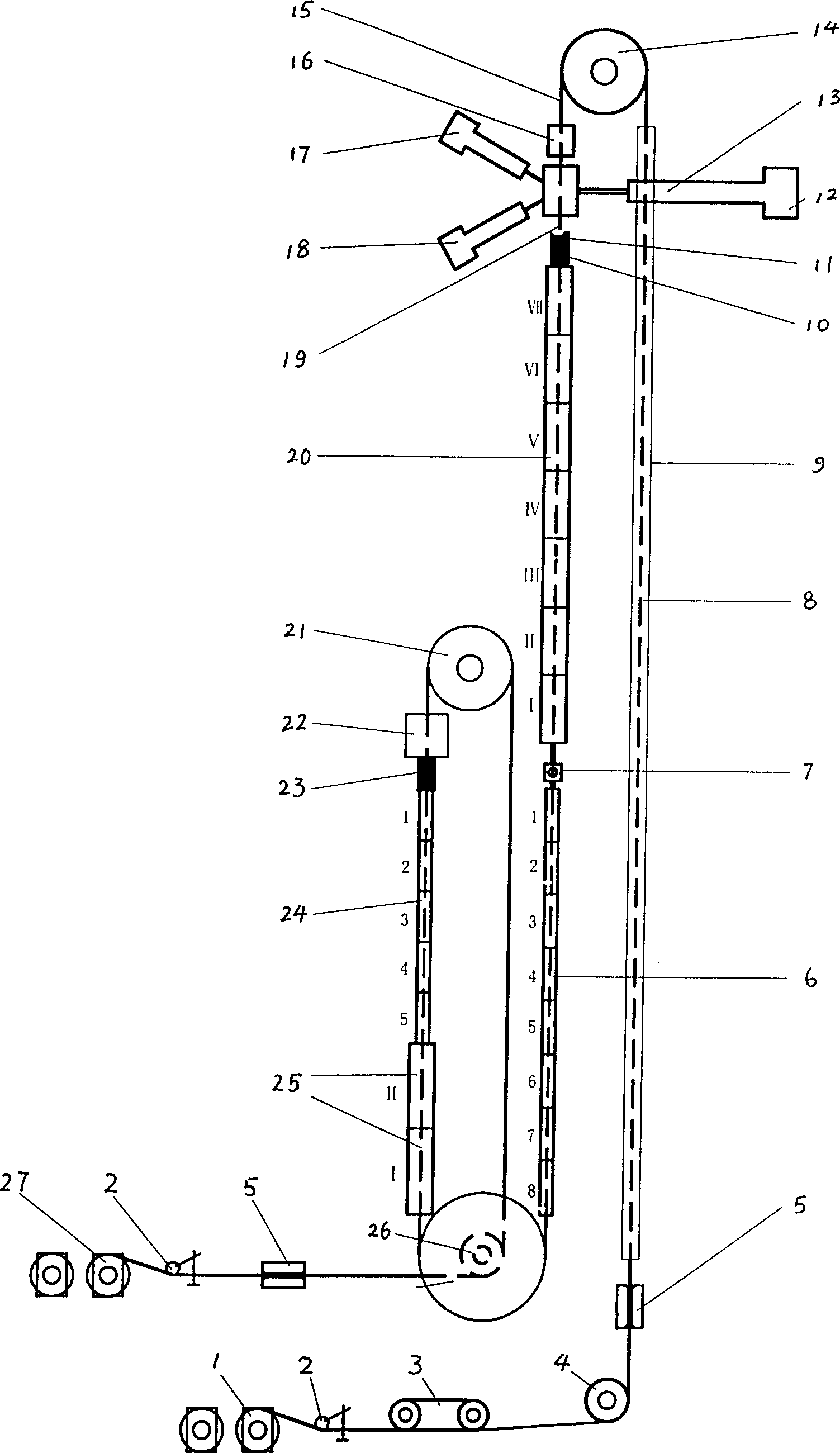

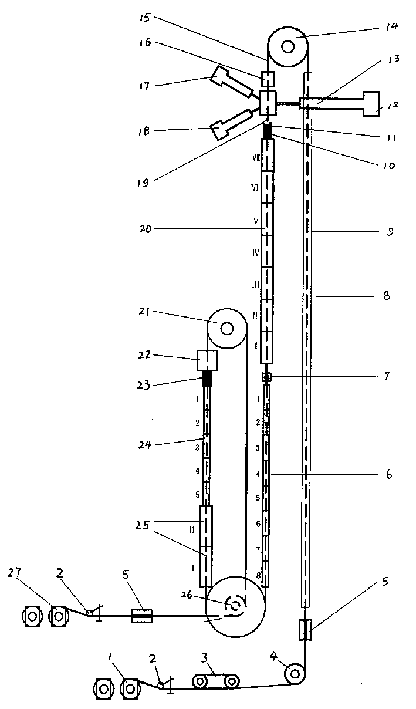

[0015] refer to figure 1 , the VCV vertical cross-linked polyethylene insulated cable production line of the present invention includes a metal conductor 15, an insulated core 19, a wire take-up device 27, a wire pay-off device 1 and extruders 12, 17, 18, and a traction wheel 21, a conductor Preheater 16, low-temperature vulcanization device 20, steering wheel 26 and stress relaxation device 25, wherein the layout of the VCV vertical cross-linked polyethylene insulated cable production line is "U" shape.

[0016] Further, in the VCV vertical cross-linked polyethylene insulated cable production line of the present invention, the pay-off device 1 is connected with the guide wheel 4 through the tension pendulum 2 and the wire storage device 3, and changes the direction through the guide wheel 4 and pulls it vertically upward on the crawler belt. 5 down through the conductor closed pipe 8 to the traction wheel 14, a conductor chip removal device 9 is also placed in the conductor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com