A kind of meta-aramid fiber and its preparation method

An aromatic polyamide and fiber technology, which is applied in the field of low thermal shrinkage meta-aramid fibers and their preparation, can solve problems such as undiscovered meta-aramid fibers, and achieves improved dimensional stability performance and reduced Thermal shrinkage, effect of suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

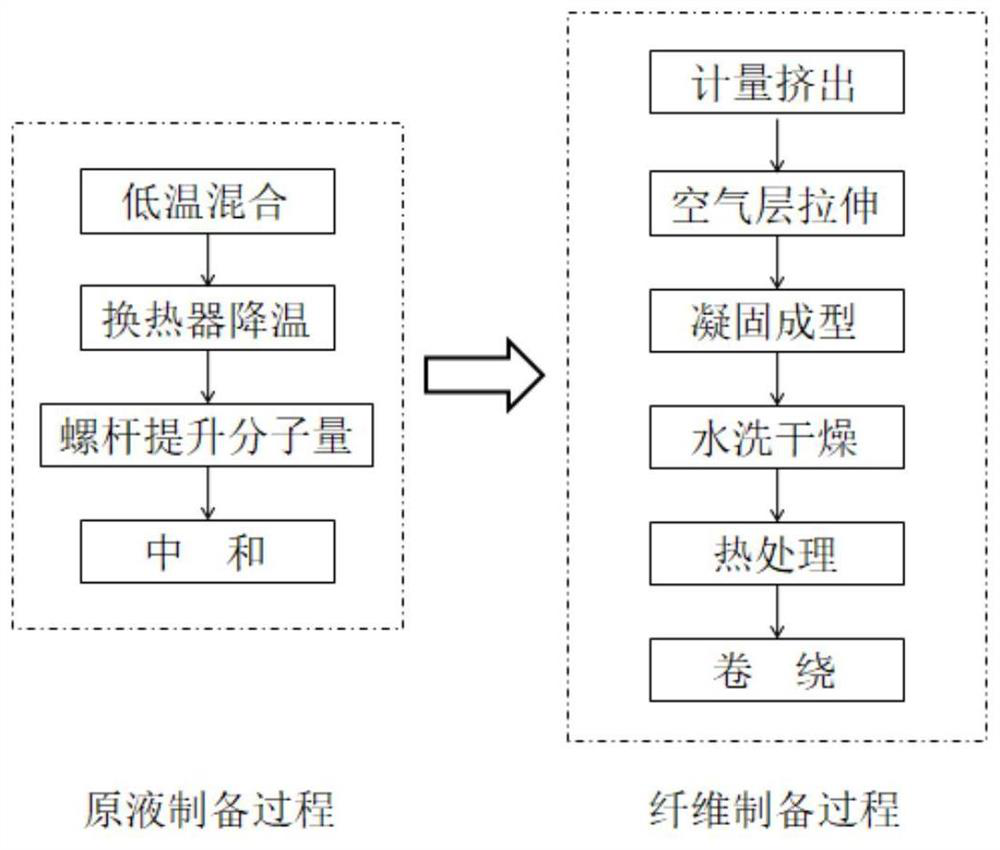

[0029] like figure 1 , A method for preparing a low heat shrinkage rate interconnection aromatic polyamide fiber in the present invention, including the following steps:

[0030] (1) Under the low temperature and nitrogen protection system, the aminenediamine, the amine dimethyl chloride, and the amide solvent are continuously mixed in the mixer, and then the mixture is cooled by the heat exchanger, and the reaction is reacted at a low temperature. Entering the screw reactor further lifts the molecular weight of the interconnection aromatic polyamide, which is neutralized to obtain a spinning stock solution.

[0031] The low temperature system is preferably -10 to -20 ° C in this step. When the temperature is high, the reaction activity is large, and there is a larger reaction heat, and the side reaction is easily occurring, and a small molecule substance is generated. When the temperature is too low, the required energy consumption is large, and then continues to reduce the tempe...

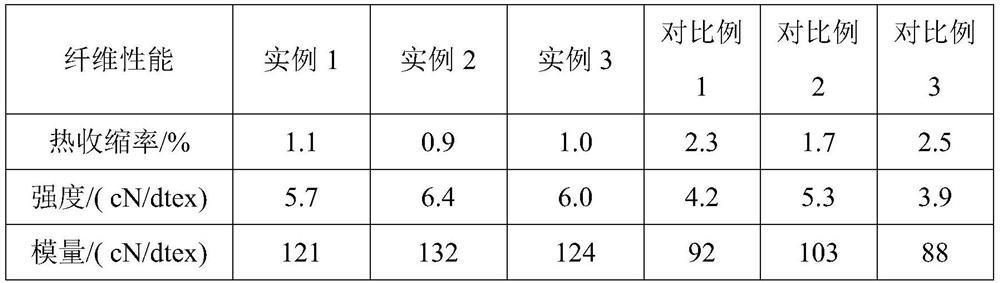

Embodiment 1

[0053] Preparation of para-aramid fibers between a low heat shrinkage of the embodiment according to the present embodiment, comprising the steps of:

[0054] (1) at low temperature (-10 deg.] C) and nitrogen protection system, the consecutive m-phenylenediamine, isophthaloyl dichloride in N, N- uniformly mixed in dimethylformamide, and then the mixture is passed through a heat exchanger to cool (cooling medium temperature of -10 deg.] C), the reaction at a low temperature, and then into the screw reactor to further enhance the molecular weight of meta-aramid, the residence time 0.8H, an inherent viscosity of 2.7. And after obtaining a spinning dope.

[0055] (2) The resultant dope is filtered to remove solid impurities and gel particles. After the number of metered through metering pump 500 and a pore diameter hole spinneret is 1.2mm, and pre-stretched in the air, an air layer height of 15mm, the draw ratio of 2.8.

[0056] (3) pre-stretched spun fibers sequentially through a coa...

Embodiment 2

[0058] Preparation of para-aramid fibers between a low heat shrinkage of the embodiment according to the present embodiment, comprising the steps of:

[0059] (1) at low temperature (-15 deg.] C) and nitrogen protection system, the consecutive m-phenylenediamine, isophthaloyl dichloride in N, N- uniformly mixed in dimethylformamide, and then the mixture is passed through a heat exchanger to cool (cooling medium temperature of -15 deg.] C), the reaction at a low temperature, and then into the screw reactor to further enhance the molecular weight of meta-aramid, the residence time 1.0H, an inherent viscosity of 2.9. And after obtaining a spinning dope.

[0060] (2) The resultant dope is filtered to remove solid impurities and gel particles. After the number of metered through metering pump 500 and a pore diameter hole spinneret is 1.2mm, and pre-stretched in the air, an air layer height is 20mm, the draw ratio of 2.8.

[0061] (3) pre-stretched spun fibers sequentially through a coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com