Photo-sensistive polyimide resin and composition and preparing method

A technology of photosensitive polyimide resin and polyimide resin, applied in the direction of photosensitive materials used in optomechanical equipment, etc., can solve the problems of inability to meet the use requirements, high dielectric constant and water absorption rate of polyimide film, etc. Achieve the effect of tolerant lithography process conditions, simple lithography process conditions, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

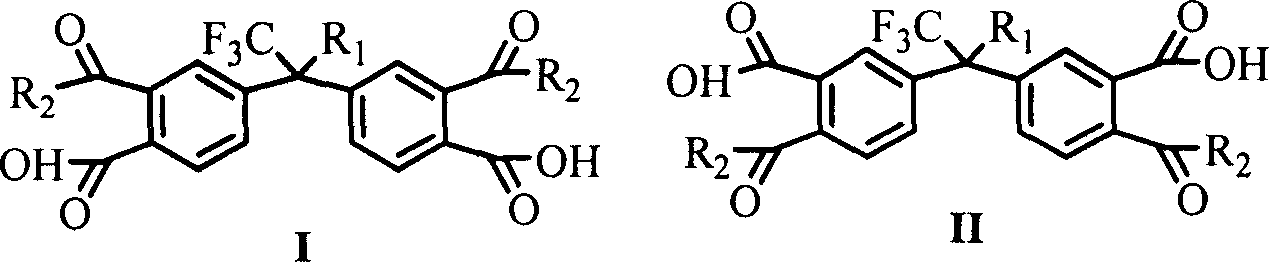

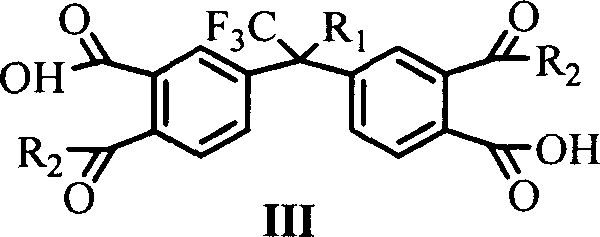

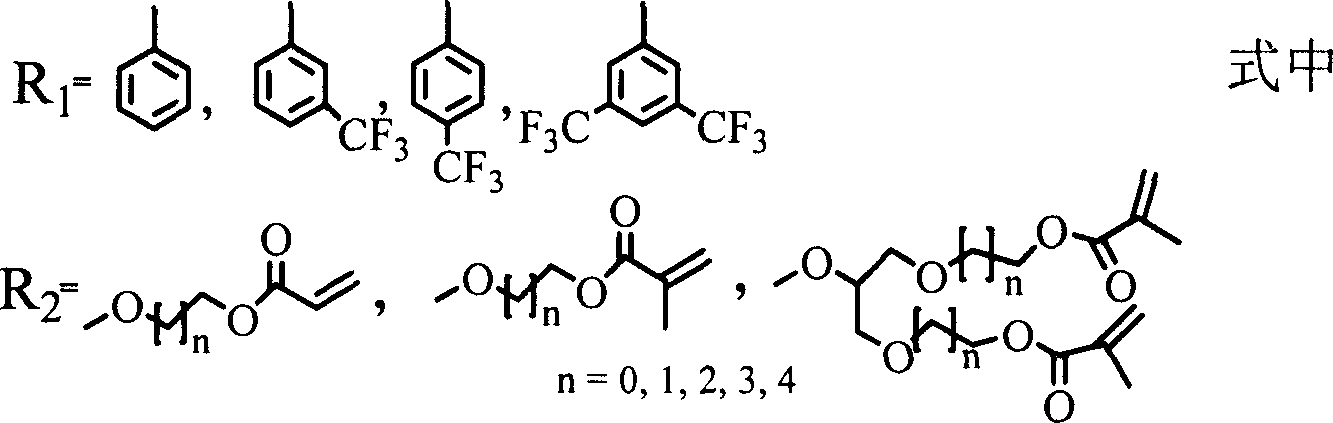

Method used

Image

Examples

Embodiment 1

[0035] Example 1 In a 1500ml three-necked round bottom flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, 260 parts by weight of g 4,4'-[2,2,2-trifluoro-1-(3-tri Fluoromethylphenyl)ethyl]bisphthalic anhydride (TFDA), 286 parts by weight of 2-hydroxyethyl methacrylate and 550 parts by weight of tetrahydrofuran. The reaction mixture was heated to 80° C. and stirred for 6 hours to generate the corresponding aromatic diacid dimethacrylate. The above product was reacted with 98 parts by weight of thionyl chloride to generate the corresponding fluorine-containing aromatic dichloride dimethacrylate (TFDE-Cl).

[0036] In a 1000ml three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, add 100 parts by weight of 4,4-diaminodiphenylmethyl ether (ODA) and 500 parts by weight of N,N-dimethylethyl ether Amide, start stirring to form a homogeneous solution; then, polycondensation reaction ...

Embodiment 2

[0040] Example 2 In a 1000ml three-necked round bottom flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, add 210 parts by weight of 4,4'-bis(2,2'-bistrifluoromethyl-4-amino Phenoxy) benzene (6FAPB) and 500 parts by weight of N, N-dimethylacetamide, start stirring, so that it forms a homogeneous solution; (TFDE-Cl) and 5 parts by weight of phenynyl phthalic anhydride undergo polycondensation reaction at room temperature for 10 hours to generate photosensitive polyimide resin (TFDE-6FAPB).

[0041] 25 parts by weight of glycidyl dimethacrylate and 10 parts by weight of epoxypropylene triethoxysilane were added to the above-mentioned photosensitive polyimide resin, and stirred at room temperature for 2 hours to form a homogeneous solution. Finally, in a dark room equipped with a yellow light, 1.2 parts by weight of 2,6-bis(4'-diethylaminobenzyl)cyclohexanone was mixed with the above resin solution, and stirred at room temperature for 2 hou...

Embodiment 3

[0043] Example 3 In a 1000ml three-necked round bottom flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, add 248 parts by weight of 4,4'-bis(2,2'-bistrifluoromethyl-4-amino Phenoxy) biphenyl (6FABB) and 500 parts by weight N, N-dimethylacetamide, start stirring to make it form a homogeneous solution; The ester (TFDE-Cl) and 3.6 parts by weight of 4-chlorophthalic anhydride undergo polycondensation reaction at room temperature for 10 hours to generate photosensitive polyimide resin (TFDE-6FABB).

[0044] Add 25 parts by weight of glycidyl methacrylate and 10 parts by weight of γ-aminopropyltriethoxysilane to the above-mentioned photosensitive polyimide resin, and stir at room temperature for 2 hours to form a homogeneous solution . Finally, in a dark room equipped with a yellow light, 0.8 parts by weight of bis(methylcyclopentadienyl)-bis(2,6-difluorobenzene)titanium was mixed with the above resin solution, and stirred at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com