Processing method of waste water containing heavy metal and dye

A dye wastewater and treatment method technology, applied in the direction of processing wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution, large sludge, unsatisfactory effect, etc., and achieve the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

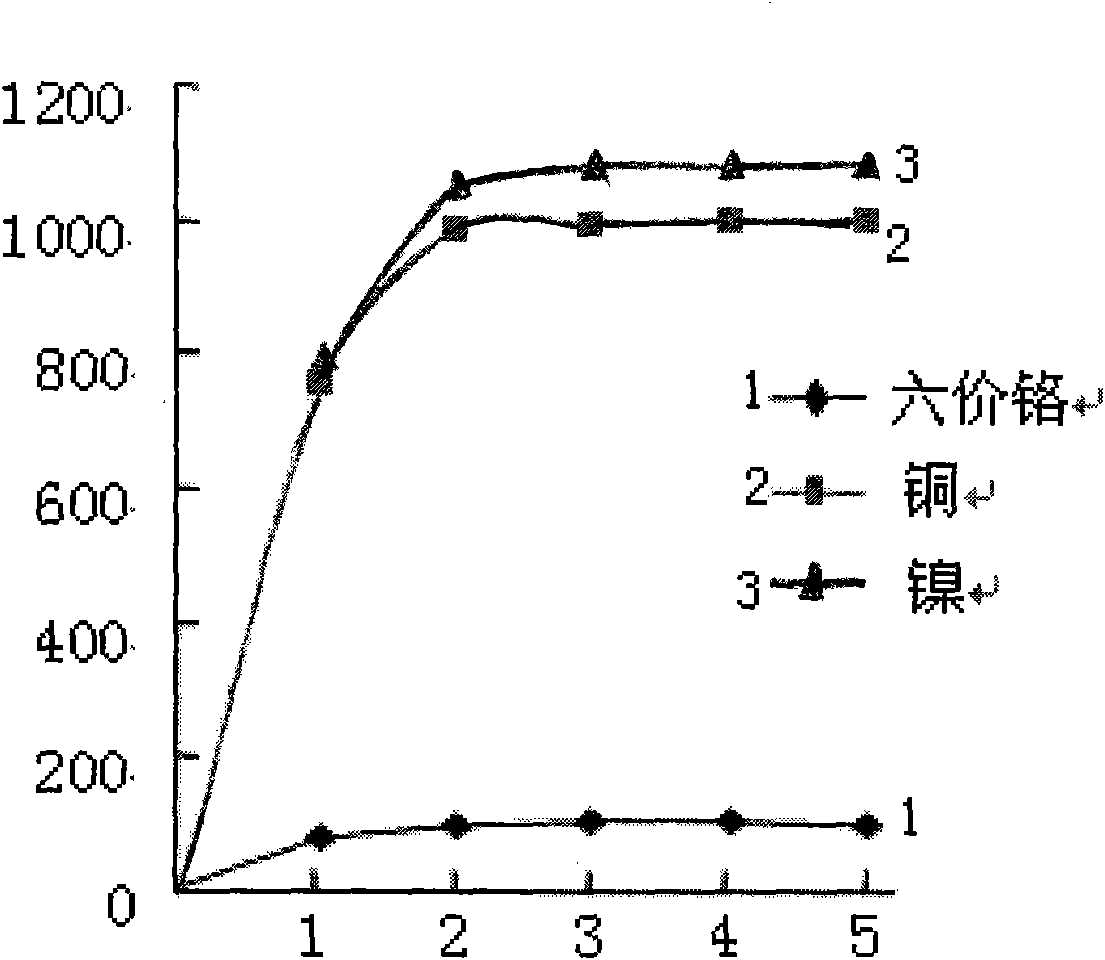

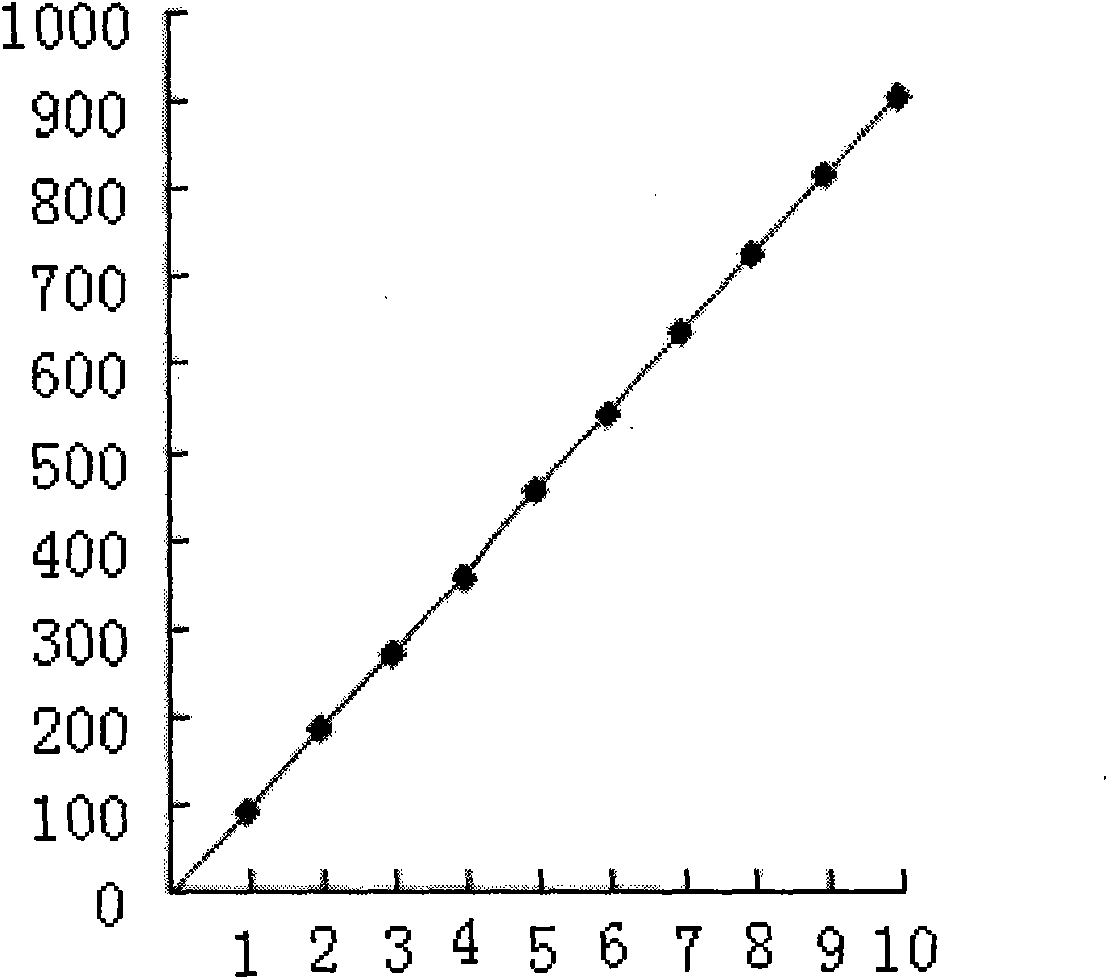

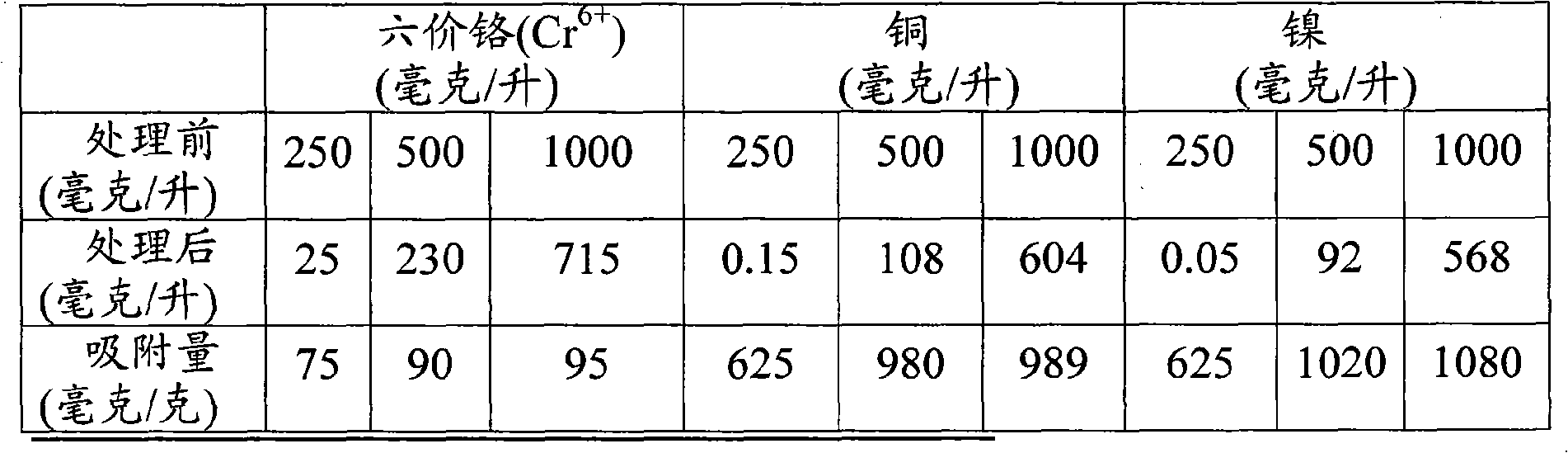

[0024] Such as figure 1 and figure 2 Shown, a kind of treatment method that contains heavy metal and dyestuff waste water of the present invention, has utilized a kind of novel adsorbent to handle heavy metal and dyestuff waste water, and this adsorbent contains ferroferric oxide micromagnetic particle and laccase, described Laccase is a copper-containing p-diphenol dioxide oxidoreductase with a classification number of EC 1.10.3.2; ferric iron tetroxide micromagnetic particles and laccase in the adsorbent are produced by a molecular formula of C 5 h 8 o 2 , a cross-linking agent called glutaraldehyde assists in the cross-linking of the bond.

[0025] The adsorption of hexavalent chromium ions by the adsorbent is achieved through step-by-step volume expansion, and the method for adsorbing hexavalent chromium ions includes the following steps: a), under the condition of partial acidity of the waste water, that is, the pH range of the waste water is 1.5~ Under the condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com