Manufacturing method and manufacturing device of light-transmitting concrete block

A technology for light-transmitting concrete and preparation devices, which is applied in the direction of optical fiber light guides, manufacturing tools, and light guides for lighting systems. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

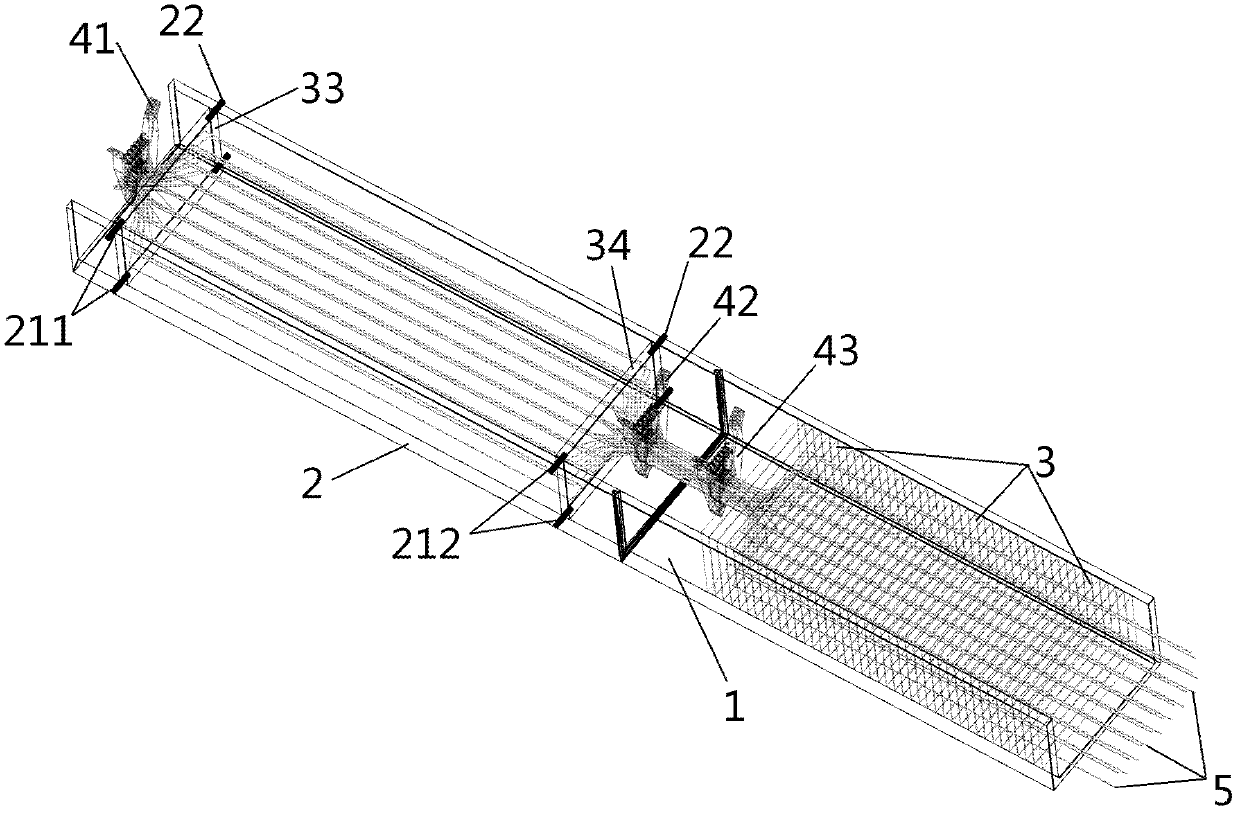

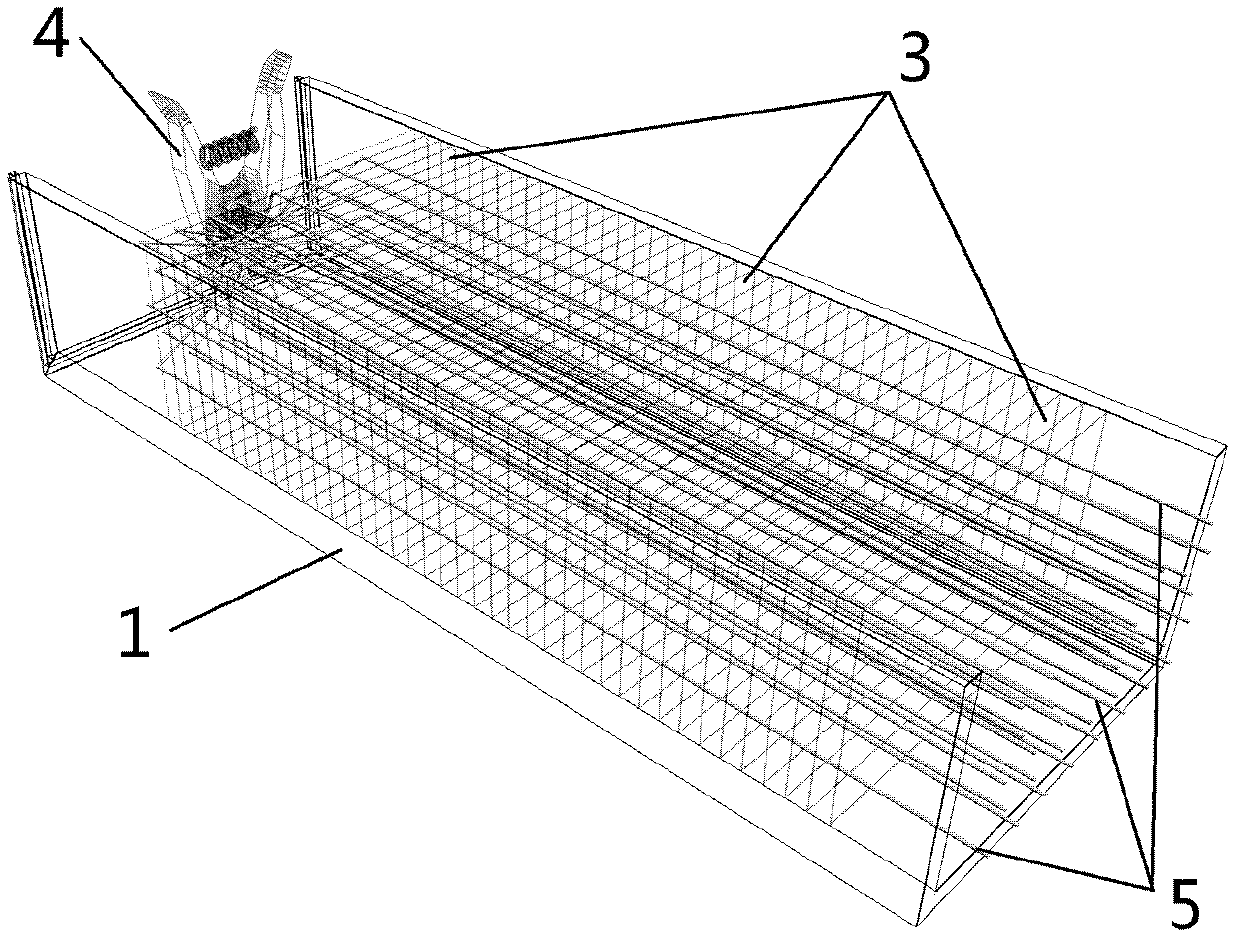

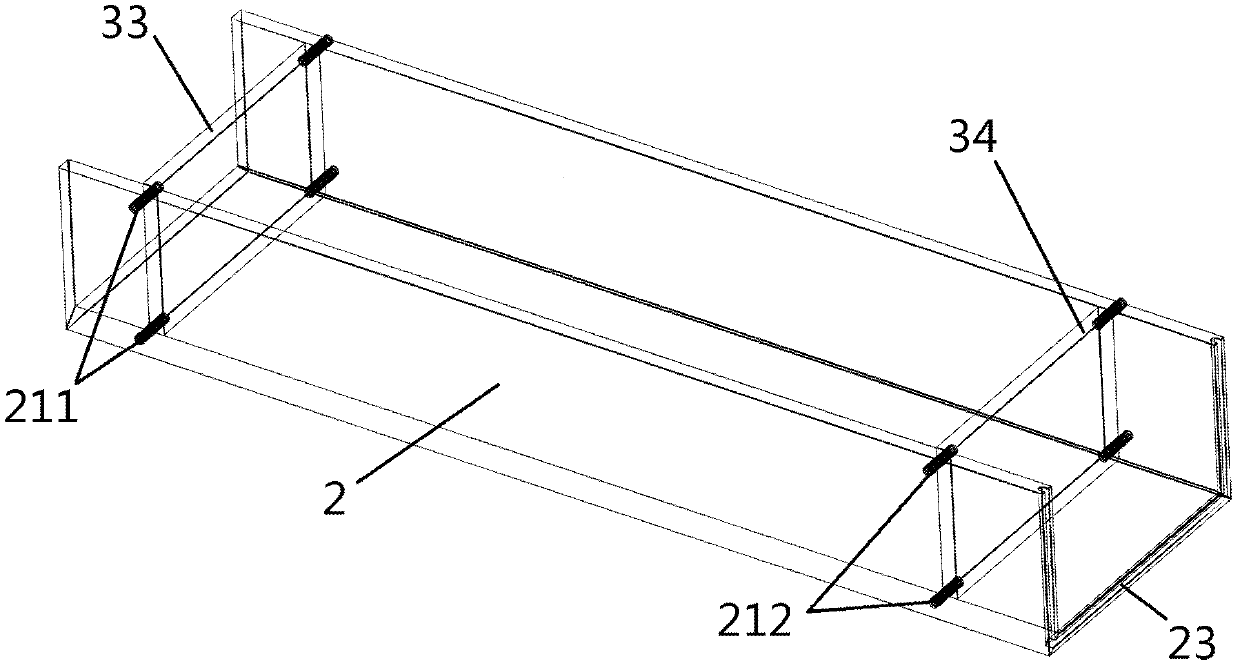

[0030] In order to better understand the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0031] A method for preparing a light-transmitting concrete block, comprising the steps of:

[0032] 1) prepare the preparation device of light-transmitting concrete block (as described below);

[0033] 2) Arrangement of optical fibers:

[0034] Place the partition 3 in the preparatory groove 1, the partition 3 includes the first partition 33 and the second partition 34, and then pass the optical fiber through the hole 32 of the partition 3; clamp the first partition with the first clamp 41 All optical fibers on the left side (i.e. outside) of plate 33 (as figure 2 shown), slide the first partition 33 and the second partition 34 into the forming groove along the preparation groove, and then slide in the forming groove, the first partition 33 slides to the fixing hole 211 of the left forming groove,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com