Flexible photovoltaic battery and method of manufacturing the same

A photovoltaic cell and manufacturing method technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as inconvenient use of flat-shaped structures, achieve large-area continuous manufacturing reduction, improve photoelectric conversion rate, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The following will further explain the technical solution of the present invention through specific examples, and at the same time show the beneficial effects that the present invention can bring.

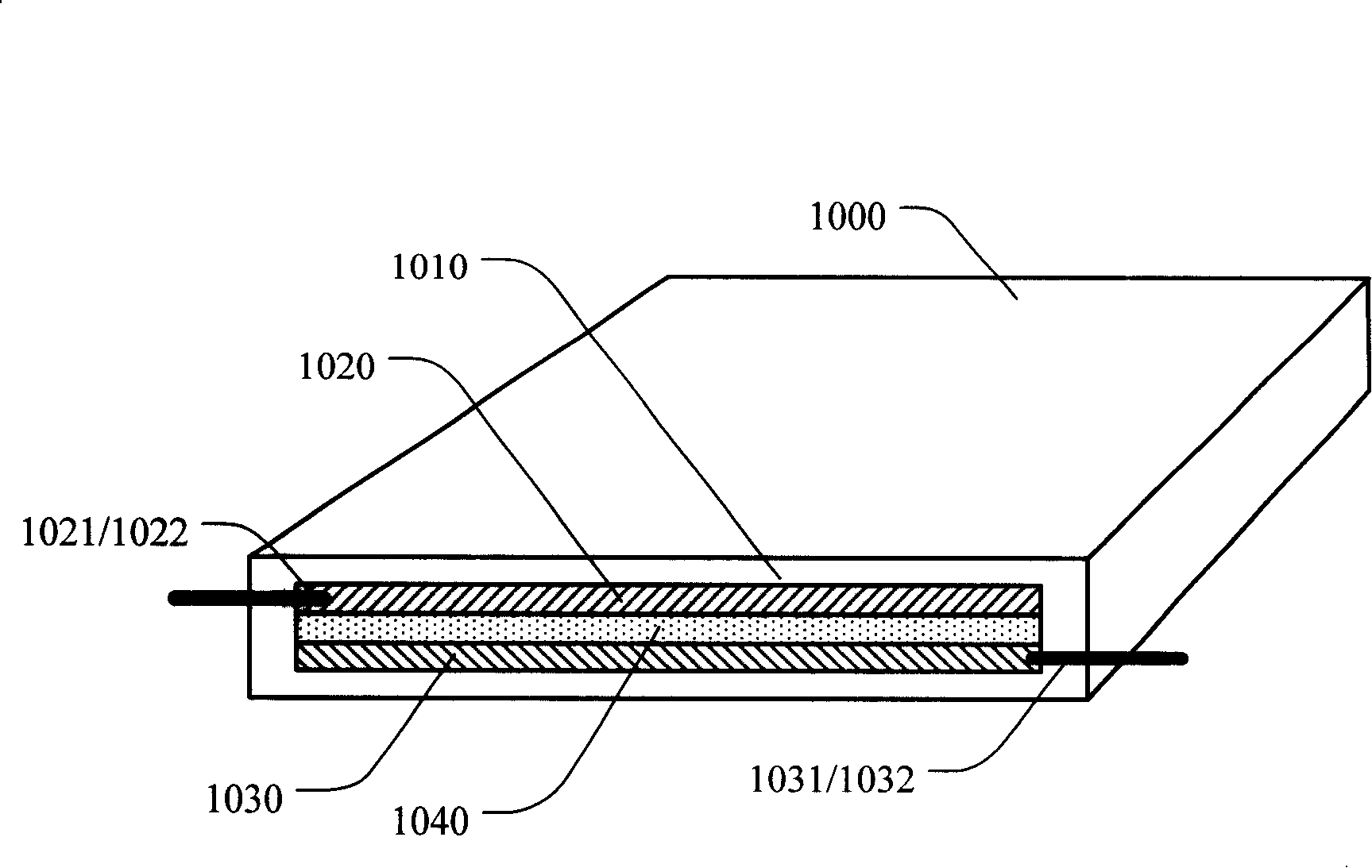

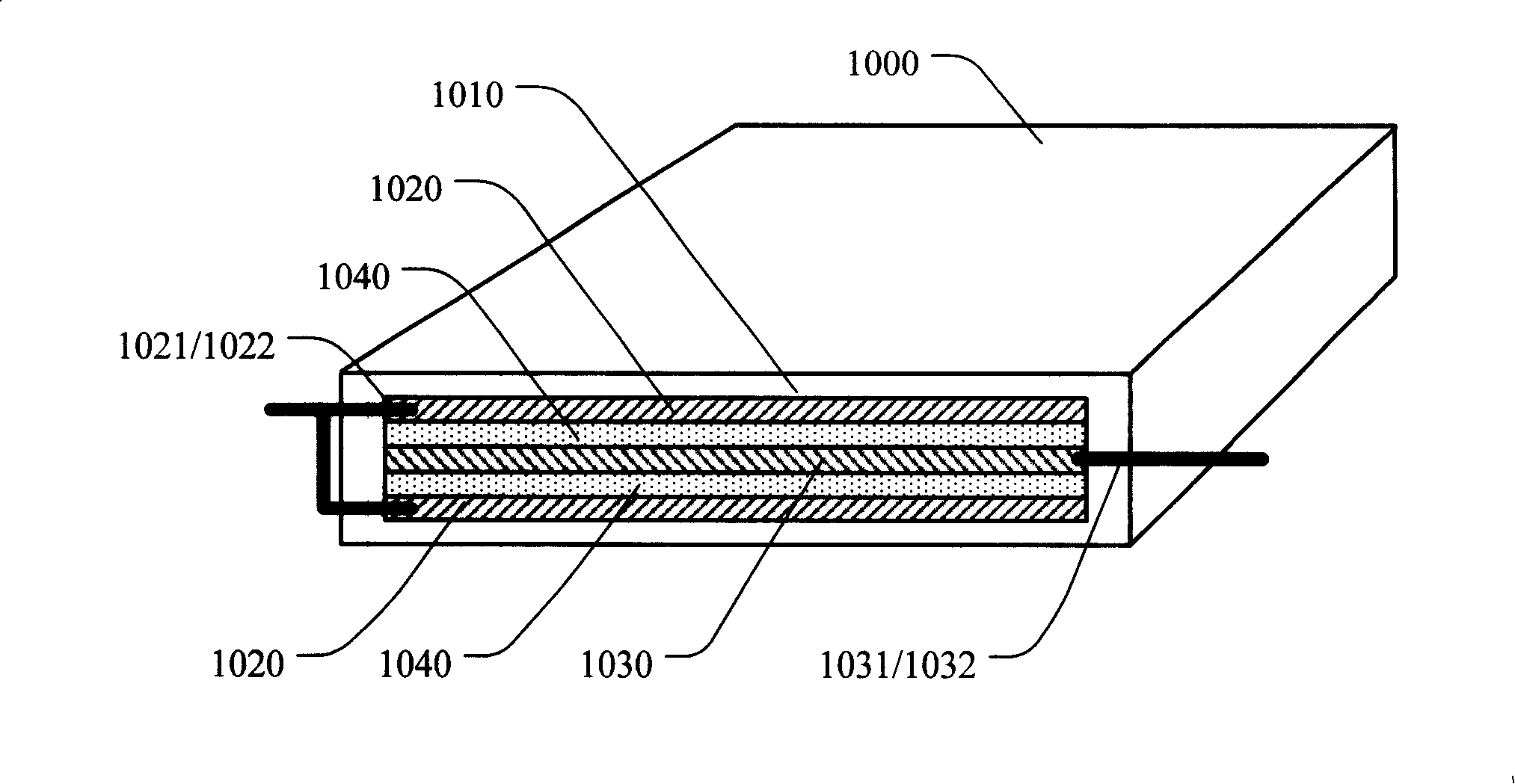

[0063] First, refer to figure 1 The first embodiment of the flexible photovoltaic cell provided by the present invention is introduced in detail.

[0064] Such as figure 1 As shown, the flexible photovoltaic cell 1000 includes: a layer of sheet-shaped flexible electrodes 1020 and corresponding electrode lead-out wires 1021, electrode lead-out wire interfaces 1022, a layer of sheet-shaped flexible counter electrodes 1030 and corresponding counter electrode lead-out lines 1031, counter electrode The lead wire interface 1032, the electrolyte 1040 disposed between the sheet-shaped flexible electrode 1020 and the sheet-shaped flexible counter electrode 1030, and the sealing of the sheet-shaped flexible electrode 1020, the sheet-shaped flexible counter electrode 1030 and the Ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com