Continuous manufacturing method for rubber masterbatch, rubber masterbatch prepared by using continuous manufacturing method and rubber product

A technology of rubber masterbatch and manufacturing method, which is applied in the rubber field, can solve the problems such as the limitation of varieties and content, the inability of the amount of filler to separate the agglomerate and water, and the difficulty of water treatment, so as to improve the physical and mechanical properties, the speed is fast, and the applicability wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

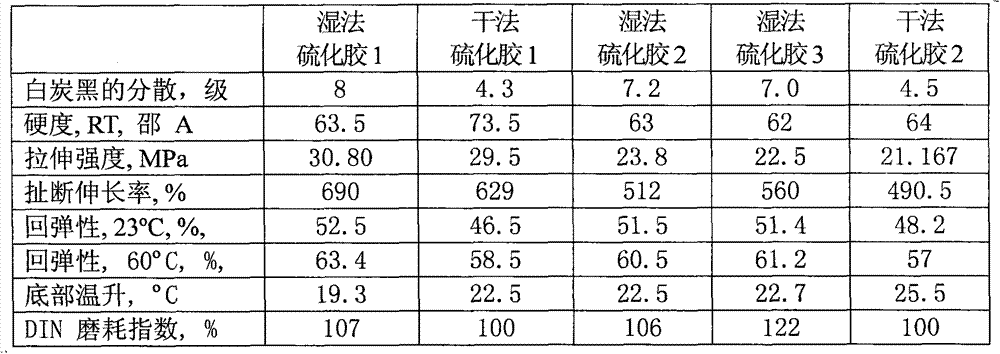

[0107] Add 60 parts of white carbon black and 6 parts of silane coupling agent Si69 to 100 parts of 8% cis-polyisoprene in n-hexane solution, and its rubber / white carbon black / Si69 / n-hexane mixture is shown in Table 3 After mixing in the primary mixing, fine mixing and fine mixing methods, it is continuously injected into the coagulator for coagulation, and then sprayed into the dryer to remove the solvent and dry to obtain the masterbatch 1.

[0108] After the masterbatch 1 is rolled evenly on the mill, add 3.5 parts of zinc oxide, 1 part of stearic acid, 1.5 parts of anti-aging agent RD, 2 parts of anti-aging agent 4020, 1.6 parts of anti-scorch agent, and then add 2 parts of accelerator CZ , 1 part of Accelerator D, 1.6 parts of sulfur, pass through the rollers, unload the sheet, and then vulcanize to positive vulcanization with a flat vulcanizer at 150°C after parking for 8 hours to obtain wet vulcanizate 1.

Embodiment 2

[0112] 78 parts of white carbon black, 6.4 parts of silane coupling agent Si69 and anti-aging agent 264 are added to 70 parts of solution-polymerized styrene-butadiene rubber and 30 parts of butadiene rubber in n-hexane solution, the rubber / white carbon black / Si69 / anti-aging agent 264 / n-hexane mixture is mixed according to the initial mixing, fine mixing and fine mixing methods shown in Table 3, and is continuously injected into the agglomerator for coagulation, and then sprayed into the dryer to remove the solvent and dry, and then further dried by a twin-screw extruder to obtain Masterbatch 2.

[0113] After wrapping the masterbatch 2 evenly on the mill, add 28 parts of high aromatic oil, 3.5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of anti-aging agent 4020, 2 parts of paraffin wax, and then release the film after mixing, and park for 8 After one hour, add 1.3 parts of accelerator CZ, 0.3 parts of accelerator D, and 1.4 parts of sulfur to the open mill, pass the...

Embodiment 3

[0117] Add 78 parts of white carbon black, 6.4 parts of silane coupling agent Si69, 28 parts of high aromatic oil, 3.5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of antioxidant 264 and 2 parts of paraffin to 70 parts of solution polystyrene butadiene rubber In the n-hexane solution of 30 parts of butadiene rubber, the rubber / white carbon black / additive / n-hexane mixture is mixed according to the initial mixing, fine mixing and fine mixing methods shown in Table 3, and then continuously injected into the coagulator to coagulate, and then Spray into a drier to remove the solvent and dry, and further dry through a twin-screw extruder to obtain masterbatch 3.

[0118] After wrapping the masterbatch 3 evenly on the open mill, add 1.3 parts of accelerator CZ, 0.3 parts of accelerator D, and 1.4 parts of sulfur, pass the roll, and release the sheet. After the mixed rubber is parked for 8 hours, it is vulcanized on a flat plate at 150 ° C. Machine vulcanization to positive v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com