LNG system with enhanced pre-cooling cycle

a technology of pre-cooling cycle and lng, which is applied in the direction of lighting and heating equipment, refrigeration and liquidation, and solidification, etc. it can solve the problems of pipeline availability or capacity exceeding the deliverability of pipeline, pipelines that are not available or are impractical, and achieve high capacity, large equipment and/or piping. , the effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

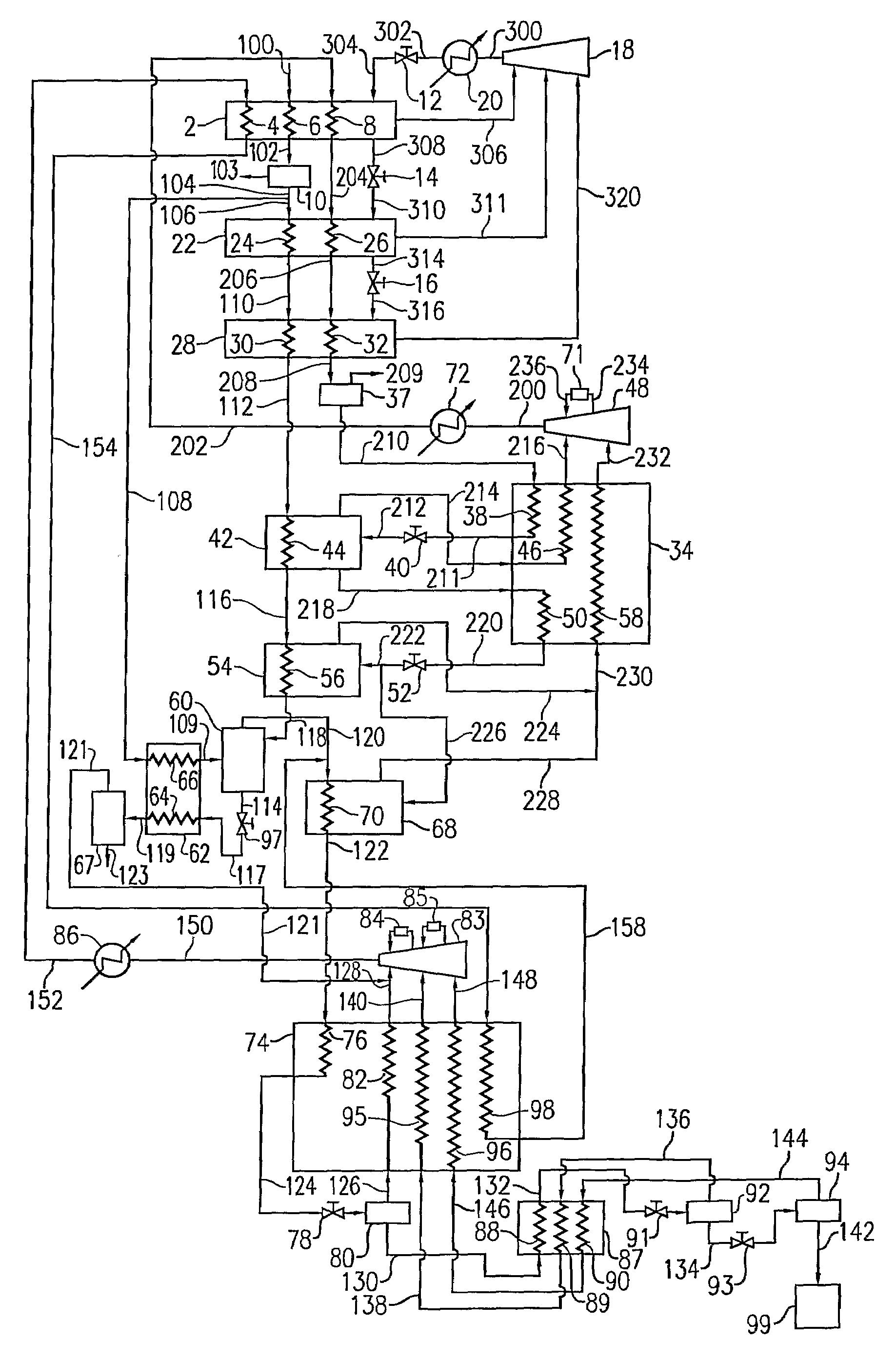

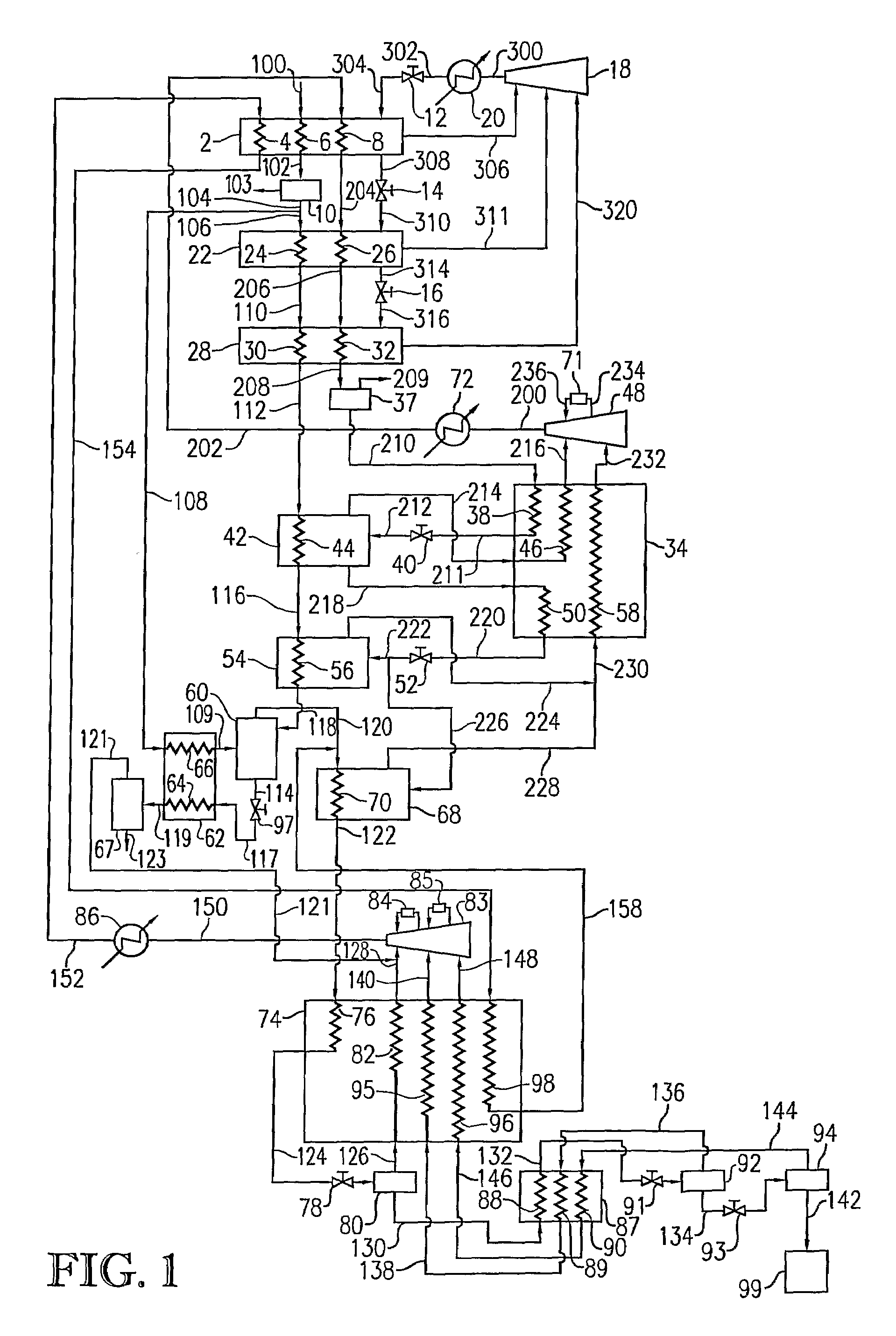

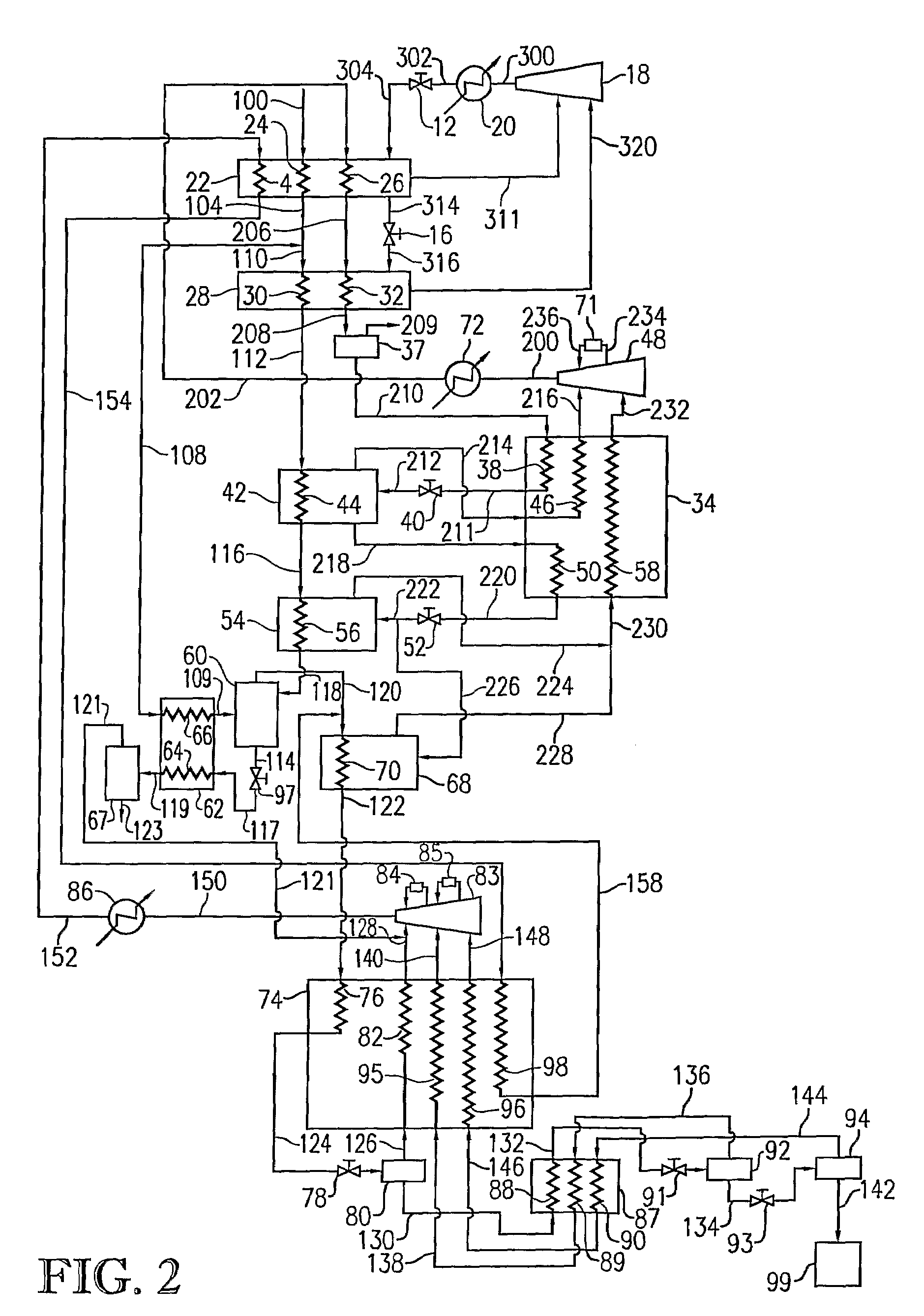

[0011]One embodiment of the present invention provides a novel natural gas liquefaction system employing a pre-cooling cycle that provides more refrigeration duty than conventional propane pre-cooling cycles.

[0012]A further embodiment of the invention is to provide a high capacity pre-cooling cycle for LNG facilities that does not require significantly larger equipment and / or piping than conventional propane pre-cooling cycles.

[0013]Another embodiment of the invention is to provide a high capacity pre-cooling cycle for LNG facilities that does not require a refrigerant compressor of significantly larger capacity than conventional compressors employed in propane pre-cooling cycles.

[0014]Still another embodiment of the invention is to provide an LNG facility / process that exhibits higher efficiency and operability in cold weather environments.

[0015]Accordingly, one aspect of the present invention concerns a process for liquefying natural gas comprising: (a) cooling a natural gas stream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com