System for the torrefaction of lignocellulosic material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

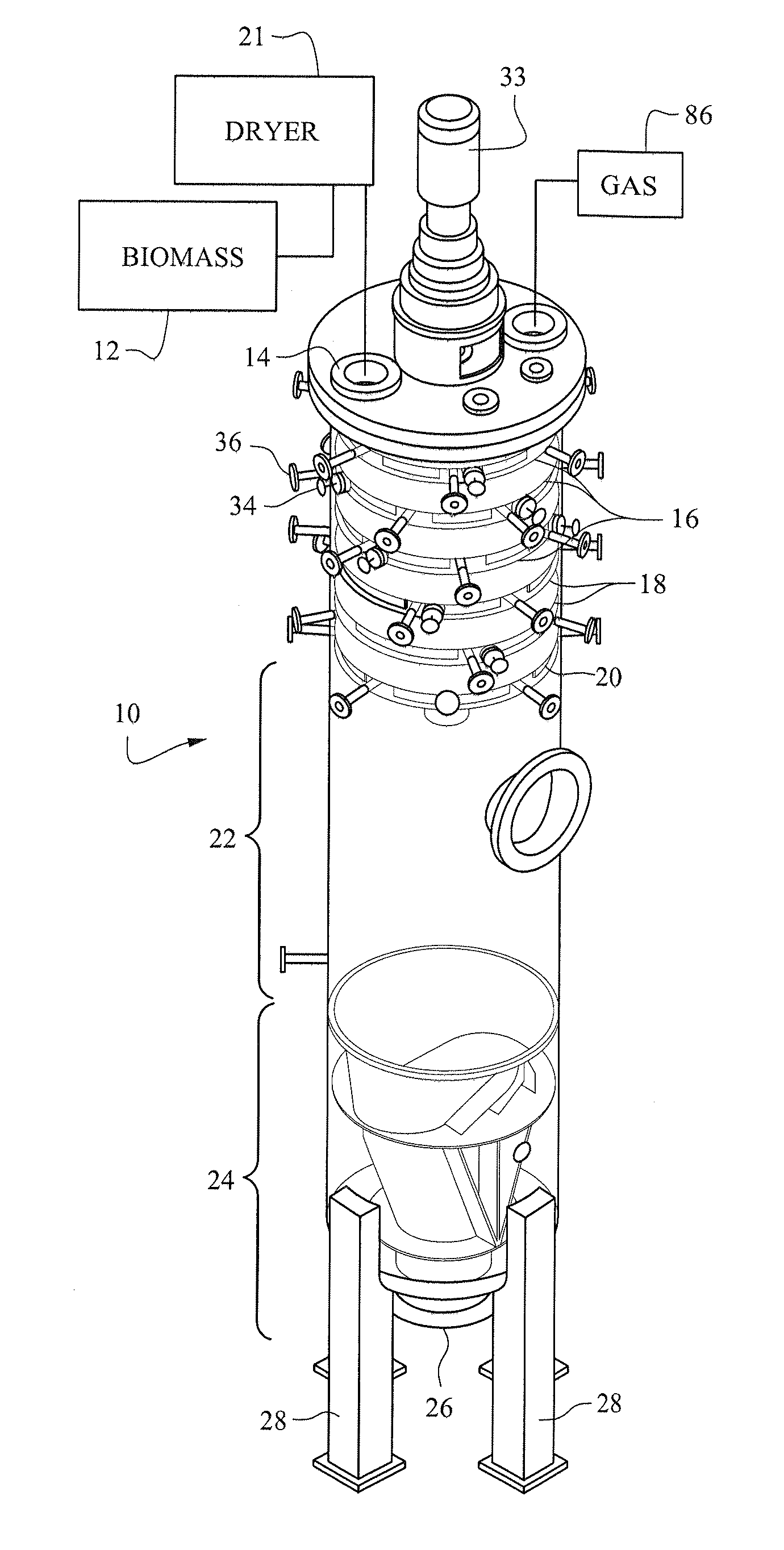

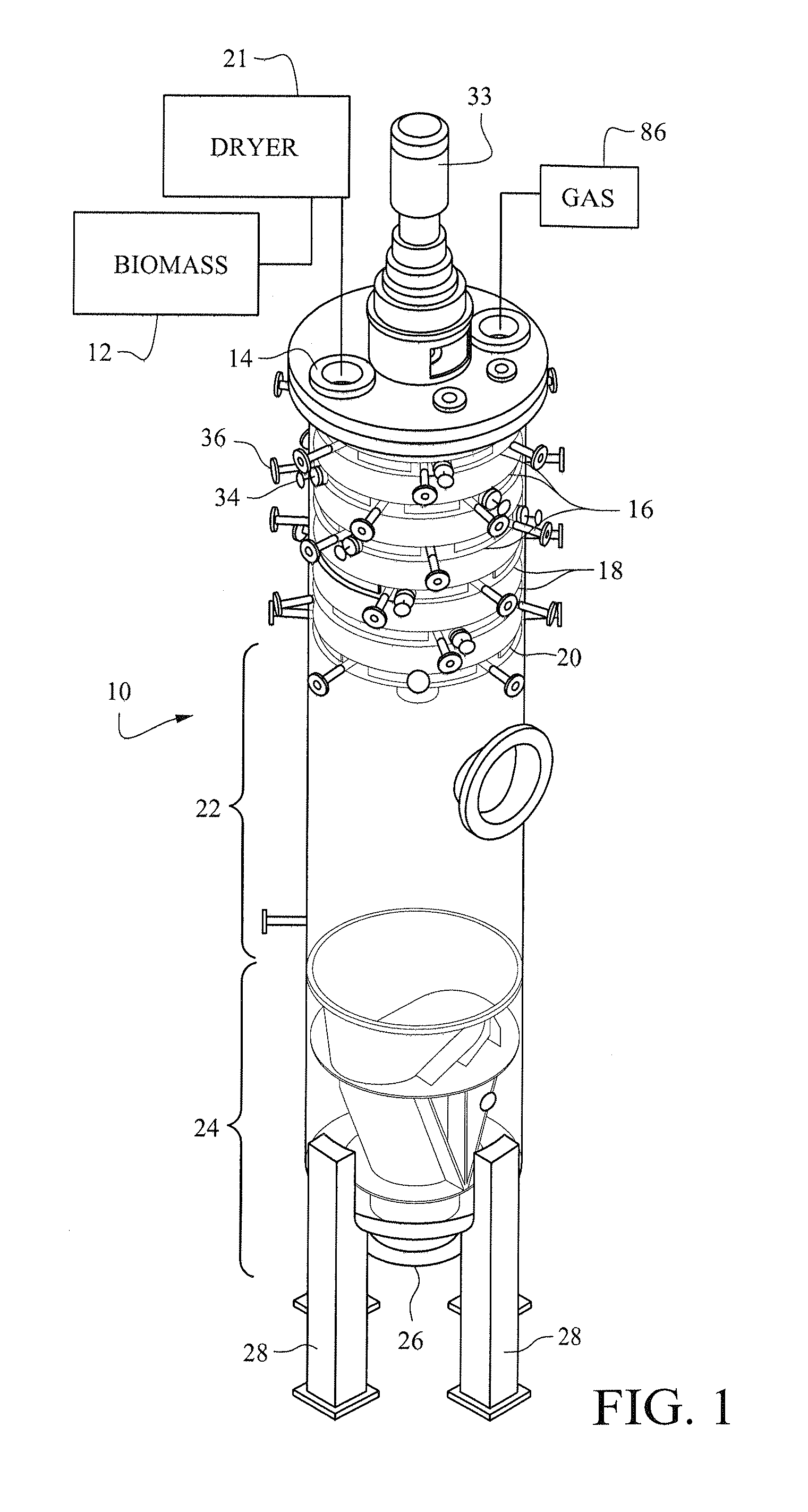

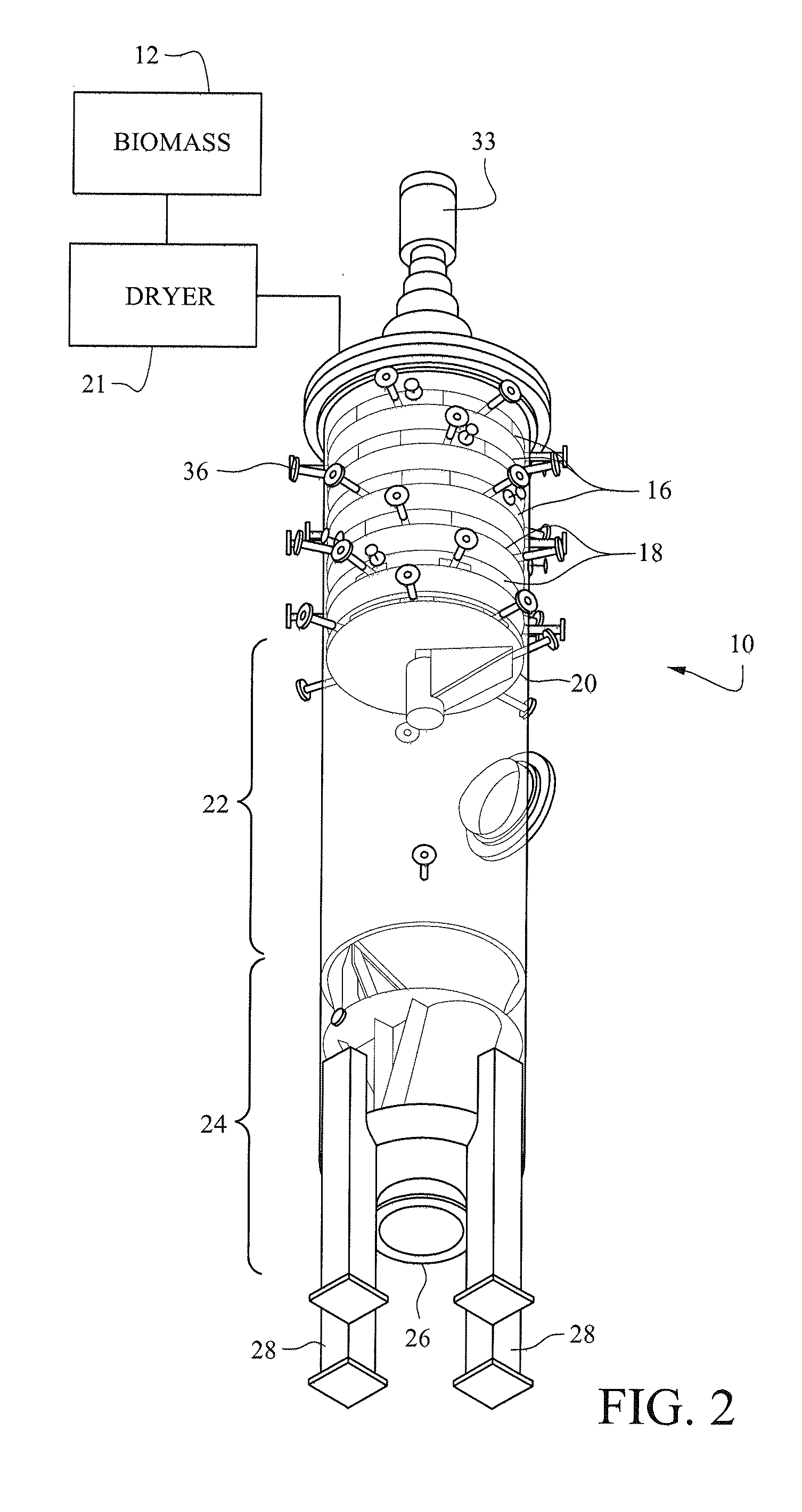

[0041]FIGS. 1 and 2 illustrate a pressurized treatment vessel 10 for receiving, treating, drying and cooling biomass material from a supply of biomass 12 through an upper inlet 14. The biomass may be wood chips, wood pulp or other comminuted cellulosic material. While moving over an upper series of drying tray assemblies 16 in the vessel, the biomass is dried. In addition or alternatively, the biomass may be dried prior to being introduced into the vessel 10.

[0042]The upper inlet 14 to the pressurized vessel may be coupled to a continuous feed, pressure isolation device, such as a conventional rotary valve or plug screw feeder, to feed the biomass into the pressurized vessel from a source of biomass at atmospheric pressure. The vessel 10 operates in a gas phase in which the dried biomass remains dry in the vessel.

[0043]The biomass may be fed to the inlet 14 to the vessel at a temperature of ambient temperature or, if a dryer 21 preheats the biomass, at 80° C. to 120° C., or higher, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com