Smoke waste heat utilization system

A flue gas waste heat and heat recovery system technology, which is applied in the field of energy saving and emission reduction, can solve the problems that it is difficult to improve the efficiency of the heat recovery system, and achieve the effects of improving utilization, reducing emissions, and reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

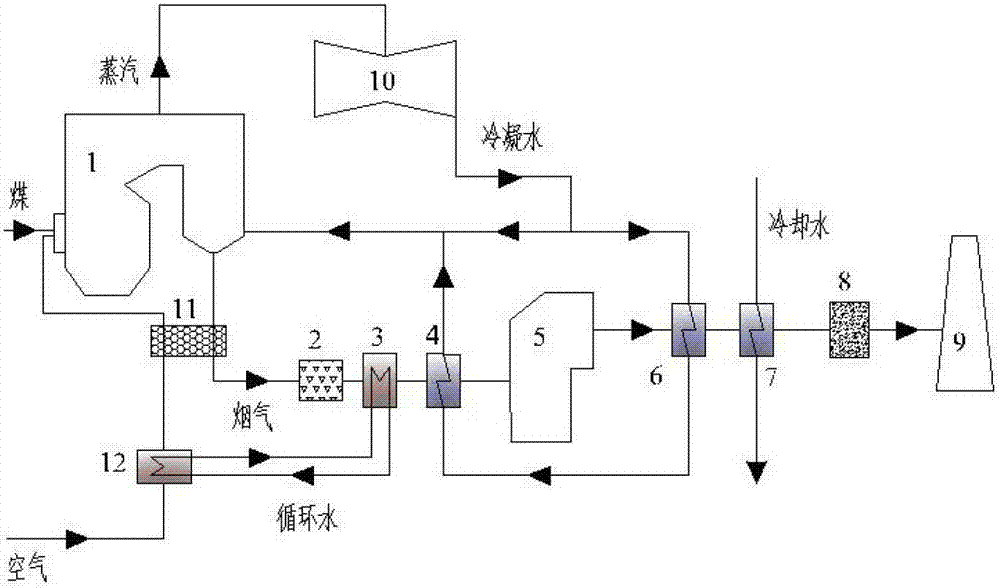

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] see figure 1 , the present invention includes a boiler 1 and an air preheater 11, an electric precipitator 2, a desulfurization tower 5, a carbon dioxide trap 8 and a chimney 9 that are connected to the flue gas outlet of the boiler 1 through a flue gas channel. An air heater 12 and an air preheater 11 are arranged in sequence on the inlet pipeline, and the first and second flue gas coolers 3 and 4 are installed between the electrostatic precipitator 2 and the desulfurization tower 5. The first flue gas cooler 3 The heat exchange tube and the air heater 12 form a closed circulation pipeline, and two condensing heat exchangers, namely the first and second condensing heat exchangers 6 and 7, are arranged between the desulfurization tower 5 and the carbon dioxide trap 8 , the cooling water is heated by the second condensing heat exchanger 7 for municipal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com