Method for producing silicon nitride powder

A silicon nitride powder and production method technology, applied in the direction of ammonium chloride, ammonium halide, etc., can solve the problems of low purity, irregular particle shape, high technical cost of silicon nitride powder, etc., and achieve the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

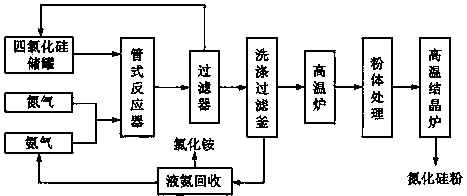

[0045] A kind of production method of silicon nitride powder of the present invention specifically comprises the following steps:

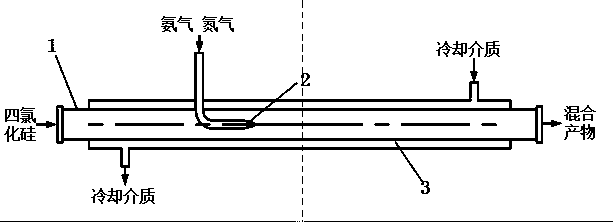

[0046] 1) Repeatedly replace the gas in the tubular reactor 1 with nitrogen to anhydrous and oxygen-free conditions, send silicon tetrachloride to the tubular reactor 1, and then pass the mixed gas of nitrogen and ammonia into the tubular reactor 1 (the molar ratio of nitrogen and ammonia is 1:1), the direction of gas flow is consistent with the flow direction of silicon tetrachloride, and the temperature of tubular reactor 1 is controlled at -50 °C. After the reaction, the mixed product is filtered through a filter to obtain the solid product Si(NH) 2 and NH 4 Cl, silicon tetrachloride returns in the silicon tetrachloride storage tank, recycles in the reaction system, filters the solid product Si(NH) that obtains 2 and ammonium chloride into the washing filter kettle, and then pass through liquid ammonia for cleaning to remove ammonium chloride...

Embodiment 2

[0050] A kind of production method of silicon nitride powder of the present invention specifically comprises the following steps:

[0051] 1) Repeatedly replace the gas in the tubular reactor 1 with nitrogen to anhydrous and oxygen-free conditions, send silicon tetrachloride to the tubular reactor 1, and then pass the mixed gas of nitrogen and ammonia into the tubular reactor 1 (the molar ratio of nitrogen and ammonia is 1:4), the direction of gas flow is consistent with the flow direction of silicon tetrachloride, and the temperature of tubular reactor 1 is controlled at -50 °C. After the reaction, the mixed product is filtered through a filter to obtain solid product and silicon tetrachloride, and silicon tetrachloride is returned to the silicon tetrachloride storage tank for recycling in the reaction system, and the solid product Si(NH) obtained by filtration is 2 and ammonium chloride into the washing filter kettle, and then pass into liquid ammonia for cleaning to remove ...

Embodiment 3

[0055] A kind of production method of silicon nitride powder of the present invention specifically comprises the following steps:

[0056] 1) Repeatedly replace the gas in the tubular reactor with nitrogen to the condition of anhydrous and oxygen-free, send silicon tetrachloride to the tubular reactor, and then pass the mixed gas of nitrogen and ammonia into the tubular reactor 1 ( The molar ratio of nitrogen and ammonia is 1:9), the direction of gas flow is consistent with the flow direction of silicon tetrachloride, and the temperature of the tubular reactor is controlled at 0 °C. After the reaction, the mixed product is filtered through a filter to obtain solid product and silicon tetrachloride, and silicon tetrachloride is returned to the silicon tetrachloride storage tank for recycling in the reaction system, and the solid product Si(NH) obtained by filtration is 2 and ammonium chloride into the washing filter kettle, and then pass into liquid ammonia for cleaning to remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com