Method for manufacturing mono-layer carbon nano pipe

A technology of single-layer carbon nanotubes and manufacturing methods, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as unobtainable, short single-layer carbon nanotubes, and difficult separation of single-layer carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0197] Acid Treatment of Single Walled Carbon Nanotubes

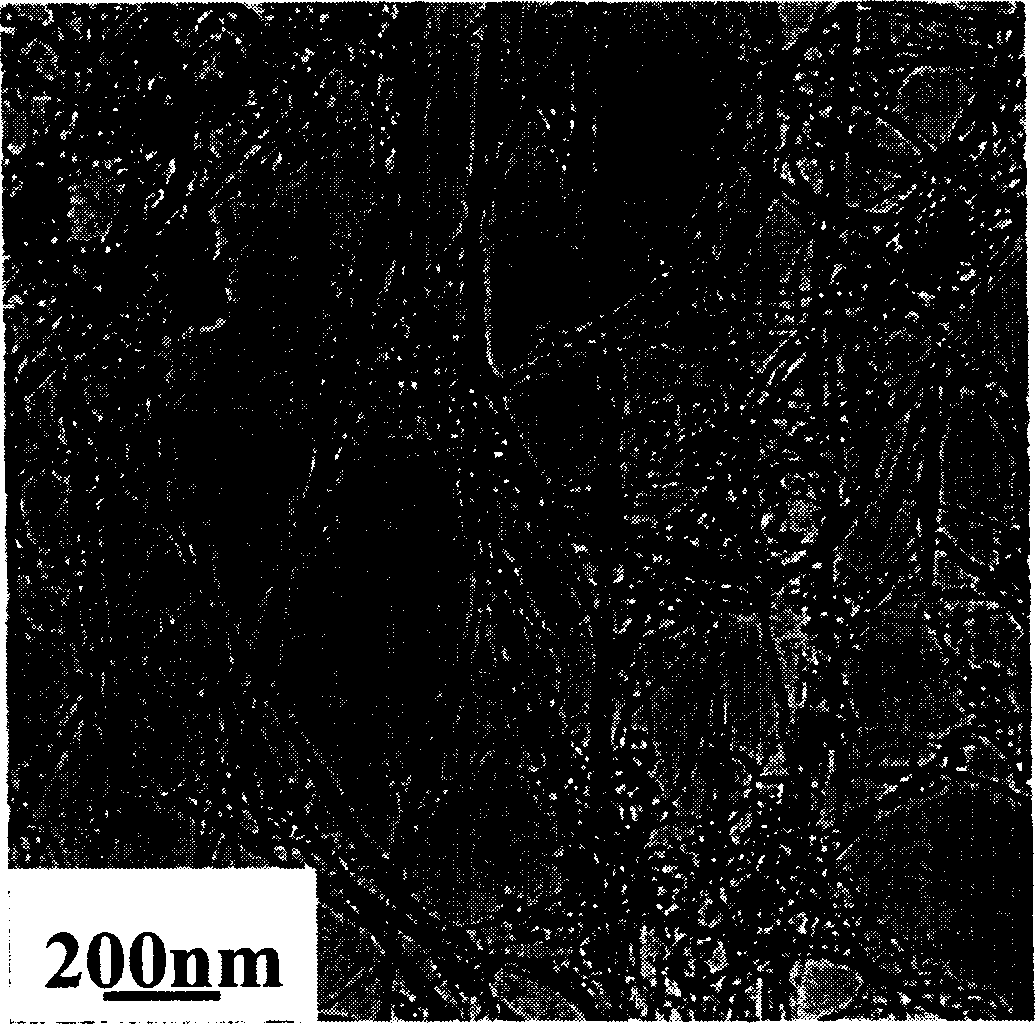

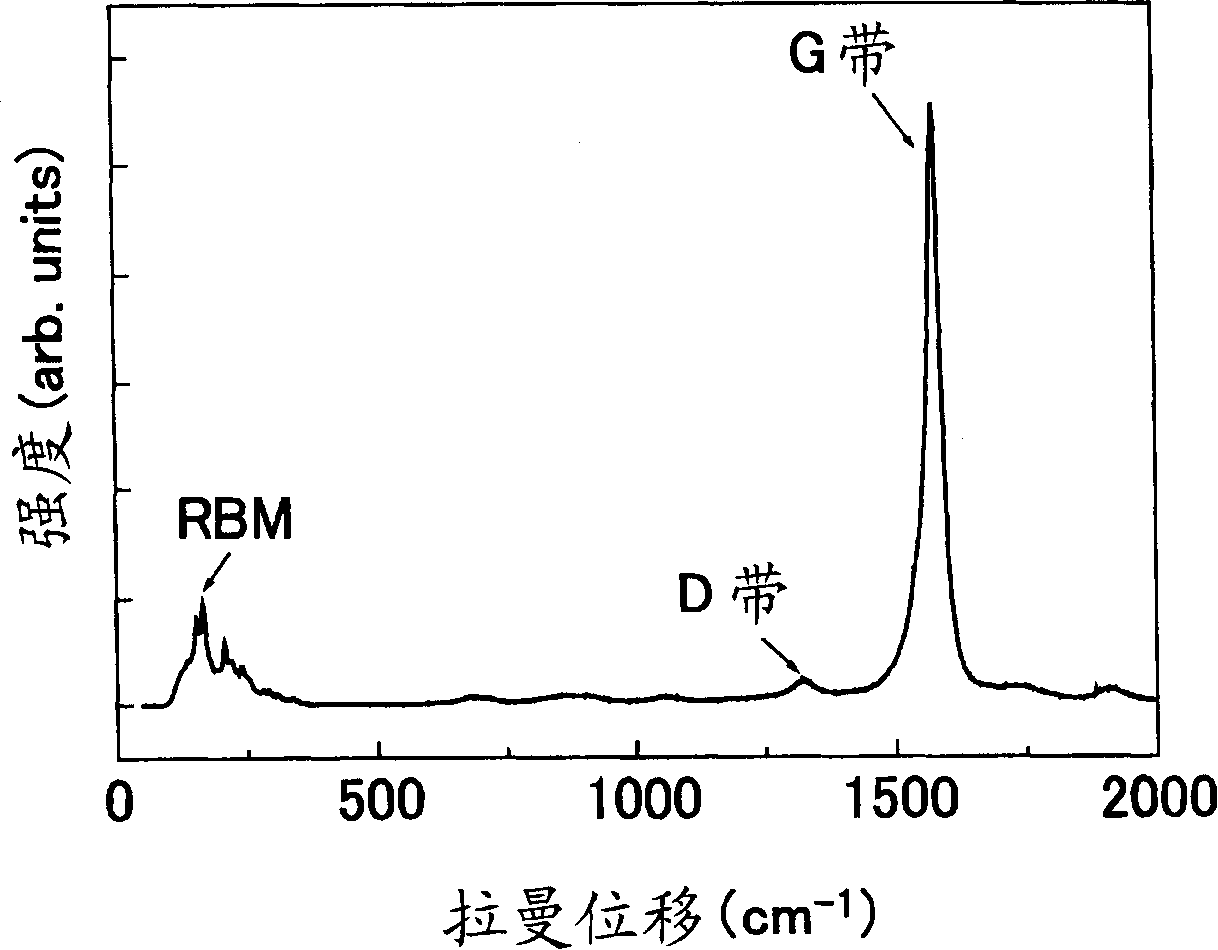

[0198] As the single-walled carbon nanotubes, those synthesized by the catalytic decomposition method of hydrocarbons were used as they were. The morphology of the single-walled carbon nanotubes is shown in figure 1 , and their resonance Raman spectra are shown in figure 2 . These single-walled carbon nanotubes are first stripped of metal impurities and subjected to a nitric acid reflux process to create defects on the tube walls. Add 1.2g of just-synthesized single-walled carbon nanotubes to 200mL of 2.6M HNO 3 The solution was then refluxed at 140° C. for 48 hours. Next, it was washed several times (4-5 times) with distilled water until the pH of the resulting sample became neutral.

[0199] Dispersant Treatment of Single Walled Carbon Nanotubes

[0200] HNO 3 The treated single-walled carbon nanotubes were suspended in 200 mL of water containing 4 mL of Triton X-100 as a surfactant and adjusted to pH 10 ...

Embodiment 2

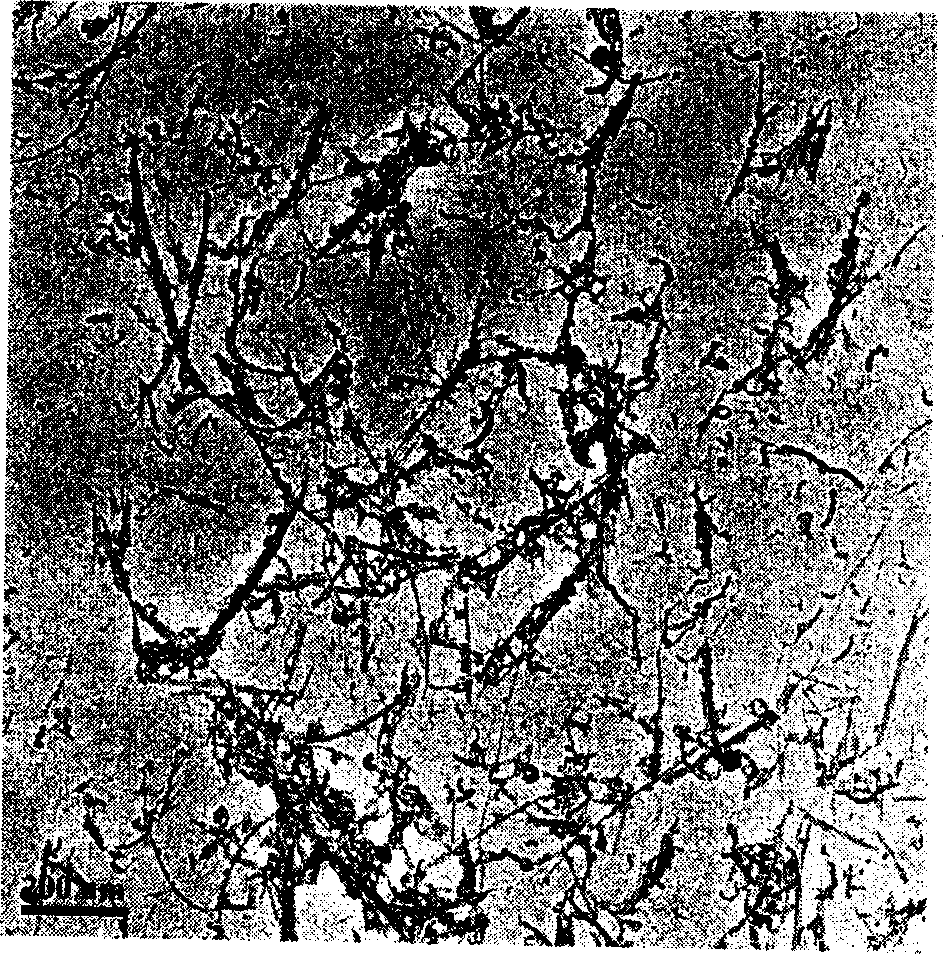

[0211] In order to remove metal impurities and improve dispersibility, HNO was obtained by the same process as used in Example 1 3 -Triton-Single-walled carbon nanotubes. However, during cut-off, instead of HNO 3 / H 2 SO 4 solution, using H 2 o 2 / H 2 SO 4 solution as a cut-off reagent. in 10 mL of 30% H 2 o 2 Add 40 mL of 96% H to the solution 2 SO 4 , prepare a fresh solution (4:1, vol / vol, 96% H 2 SO 4 / 30%H 2 o 2 ). After lowering the temperature to 35°C, immediately disperse 25 mg of HNO in the mixture 3 -Triton-single-walled carbon nanotubes, followed by ultrasonic treatment at this temperature for 30 hours. After sonication, the suspension was added to 1 L of distilled water to quench the oxidation reaction. Next, the solution was filtered and washed several times with distilled water until the final pH reached 7. Next, the obtained sample was dried at 120° C. for 24 hours. TEM images of these samples at different magnifications Figure 8 A and B ar...

Embodiment 3

[0216] In order to remove metal impurities and improve dispersibility, HNO was obtained by the same process as used in Example 1 3 -Triton-Single-walled carbon nanotubes. However, during cut-off, instead of HNO 3 / H 2 SO 4 solution, using (NH 4 ) 2 SO 8 / H 2 SO 4 solution as a cut-off reagent. 25mg of HNO 3 -Triton-single-walled carbon nanotubes in 50 mL of 96% H 2 SO 4 Pre-disperse for 1 hour to homogenize the mixture. Next, add 4 g of ammonium persulfate (NH 4 ) 2 S 2 o 8 As an oxidizing agent, the mixture was subjected to ultrasonic treatment at 35-40° C. for 4, 8, 20, and 30 hours. After sonication, the suspension was added to 1 L of distilled water to quench the oxidation reaction. Next, the solution was filtered and washed several times with distilled water until a final pH of 7 was reached. Next, the obtained sample was dried at 120° C. for 24 hours. The TEM image of the sample subjected to ultrasonic treatment for 20 hours is shown in Figure 10 mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com