Device and method for adsorbing and removing methyl chlorosilane impurities to prepare high-purity trichlorosilane

A technology of high-purity trichlorosilane and monomethyldichlorosilane is applied in chemical instruments and methods, halogenated silanes, silicon compounds, etc., to achieve the effects of prolonging the service cycle, simple process flow, and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

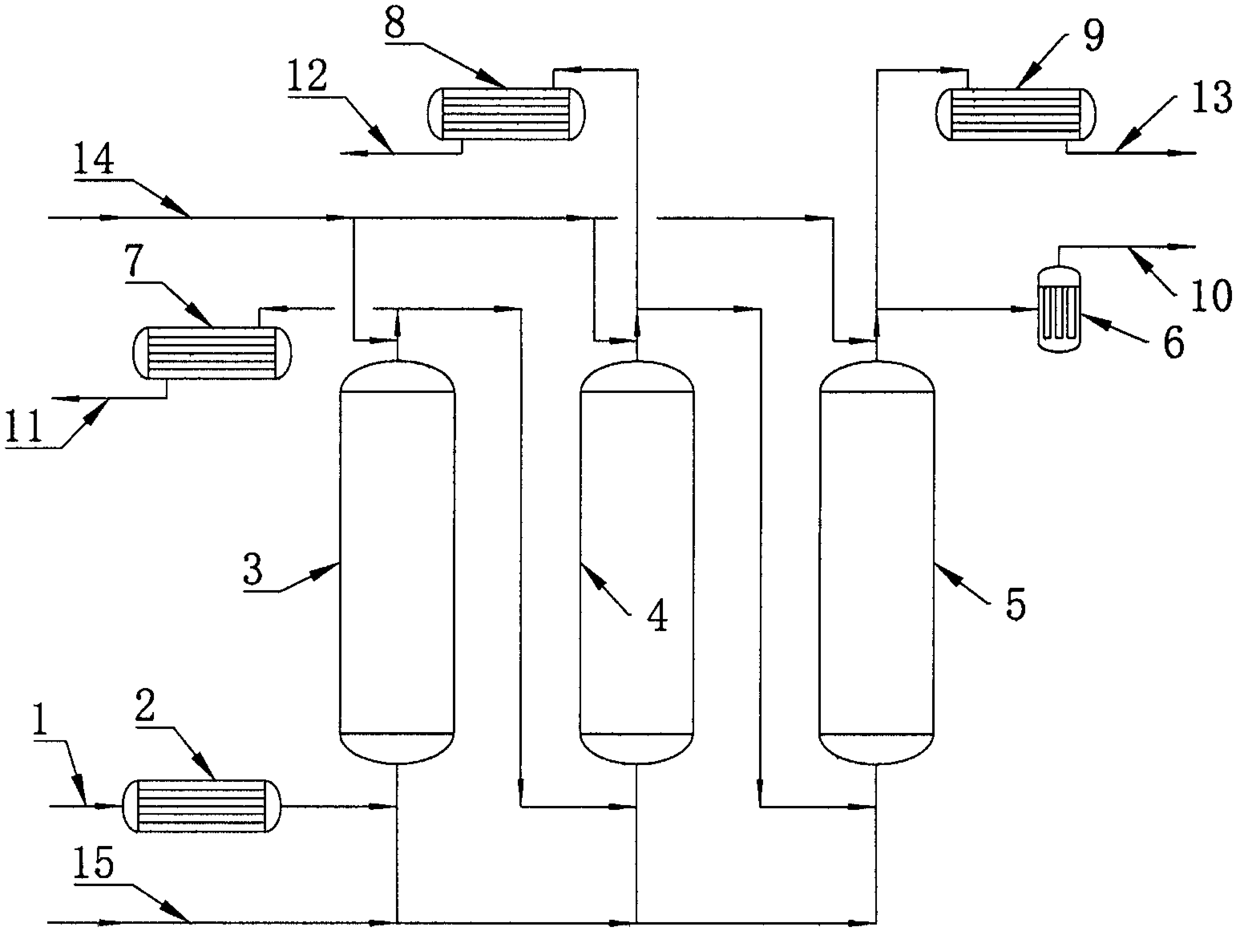

[0035] The trichlorosilane rectification process of an enterprise is as follows: light removal first, then heavy removal, second light removal and second weight removal; the trichlorosilane after the second light removal is taken as the raw material of the adsorption device, and firstly passed through the deep The cooler is cooled to 0°C, then enters the adsorption device at a flow rate of 20ml / min, and passes through the three-stage adsorption columns in sequence (the adsorbent amount of each adsorption column is 200g), the particle size of the semi-carbonized resin adsorbent packed in the A adsorption column 0.6 ~ 0.8mm, the average pore diameter is The specific surface area is 33m2 / g. The dimethyl monochlorosilane directional adsorbent packed in the B adsorption column has a particle size of 800-1600 μm and a pore size of The specific surface area is 700m2 / g. The monomethyldichlorosilane directional adsorbent packed in the C adsorption column has a particle size of 800-...

Embodiment 2

[0041] The trichlorosilane product obtained from the secondary weight removal tower was analyzed, and compared with the trichlorosilane product obtained from the second weight removal tower, a primary rectification purification was added. Among them, the theoretical plate number of the secondary weight removal tower is 240, and the reflux ratio is 6.2. The analysis results are shown in Table 2.

[0042] [Table 2]

[0043]

[0044] The same trichlorosilane material, after primary distillation and purification, the content of dimethyl monochlorosilane can only be reduced from 0.8ppmw to 0.4ppmw, and the content of monomethyldichlorosilane can only be reduced from 1.0ppmw to 0.5 ppmw, and above the lower detection limit of the analytical instrument. For the removal of trace impurities with relatively close boiling points, rectification technology is not as effective as adsorption technology, and cannot meet the production of electronic-grade polysilicon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com