Method for measuring carbon concentration in polycrystalline silicon

A determination method and technology for polysilicon, which can be used in measurement devices, color/spectral properties measurement, material analysis by optical means, etc., can solve the problems of small effective segregation coefficient of carbon impurities and difficulty in accurately measuring the carbon concentration of polysilicon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

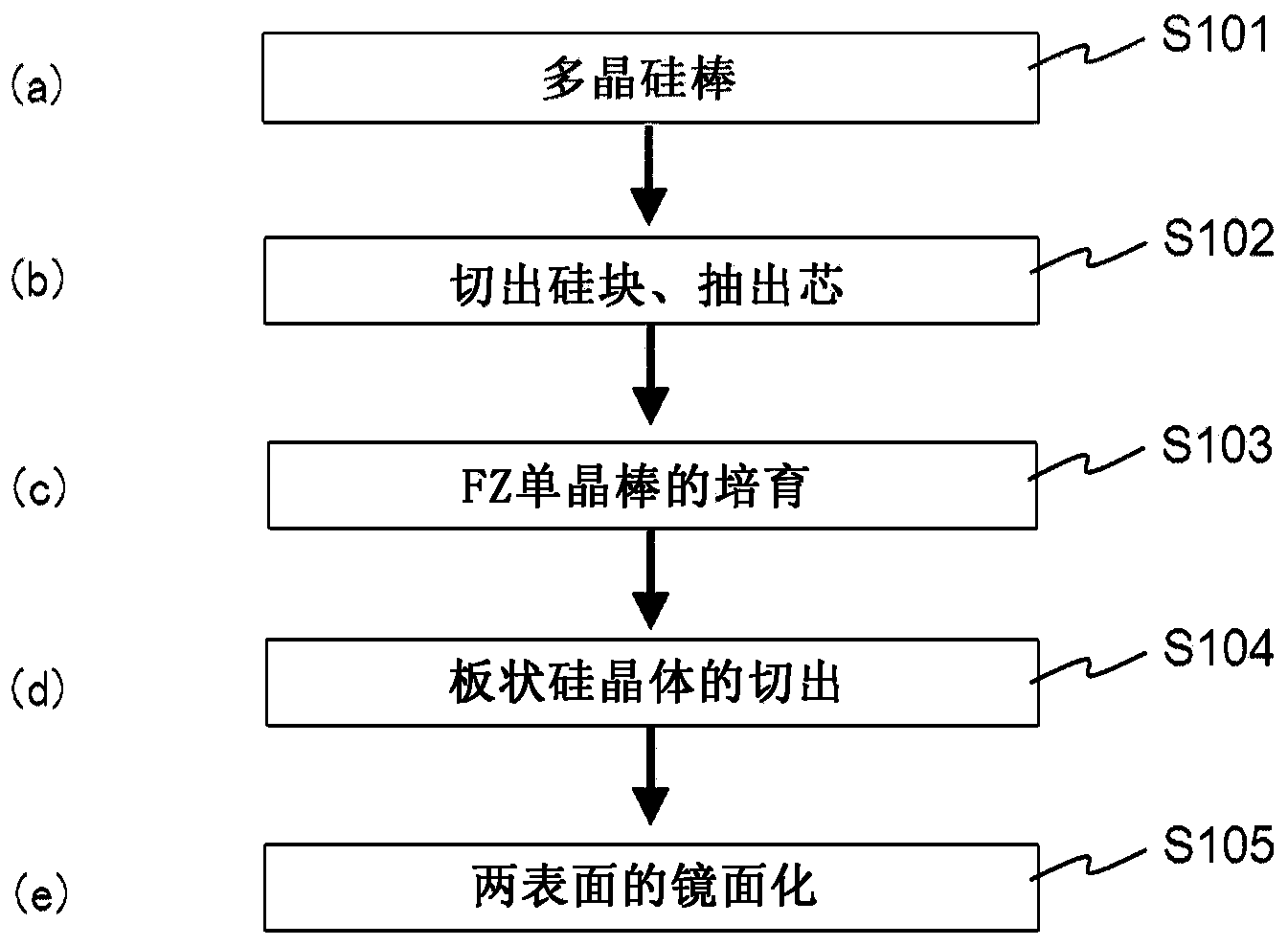

[0032] Preparation of samples for carbon concentration measurement: figure 1 It is a figure which shows an example of the preparation procedure of the sample for carbon concentration measurement. First, six polycrystalline silicon rods obtained by vapor phase growth by the Siemens method were prepared ( S101 ). For these polycrystalline silicon rods, cores (silicon blocks) each having a length of 150 mm and a diameter of 20 mm were extracted in a cylindrical shape from the longitudinal direction ( S102 ). Hereinafter, these are called cores 1-6. Next, FZ single crystal silicon rods having a diameter of approximately 10 mm and a length of approximately 200 mm are grown by using the aforementioned cores 1 to 6 as raw materials ( S103 ).

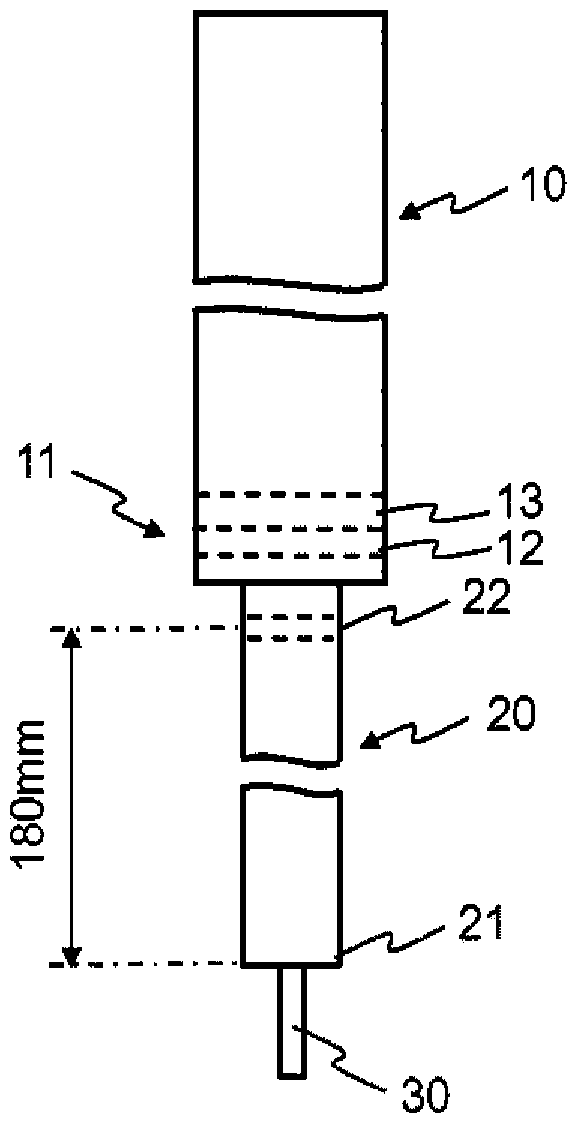

[0033] figure 2 It is a diagram for explaining cutting out a plate-shaped silicon crystal from an FZ single crystal silicon rod and a holding part. In this figure, symbol 10 is a core (silicon block), symbol 20 is an FZ single crystal silic...

Embodiment

[0050] Example: According to the above steps, one piece of plate-shaped FZ monocrystalline silicon with a thickness of 2.000 mm and one piece of plate-shaped polysilicon with a thickness of 2.006 mm and 2.477 mm were prepared from polycrystalline silicon rods, and mirror grinding was performed on both surfaces.

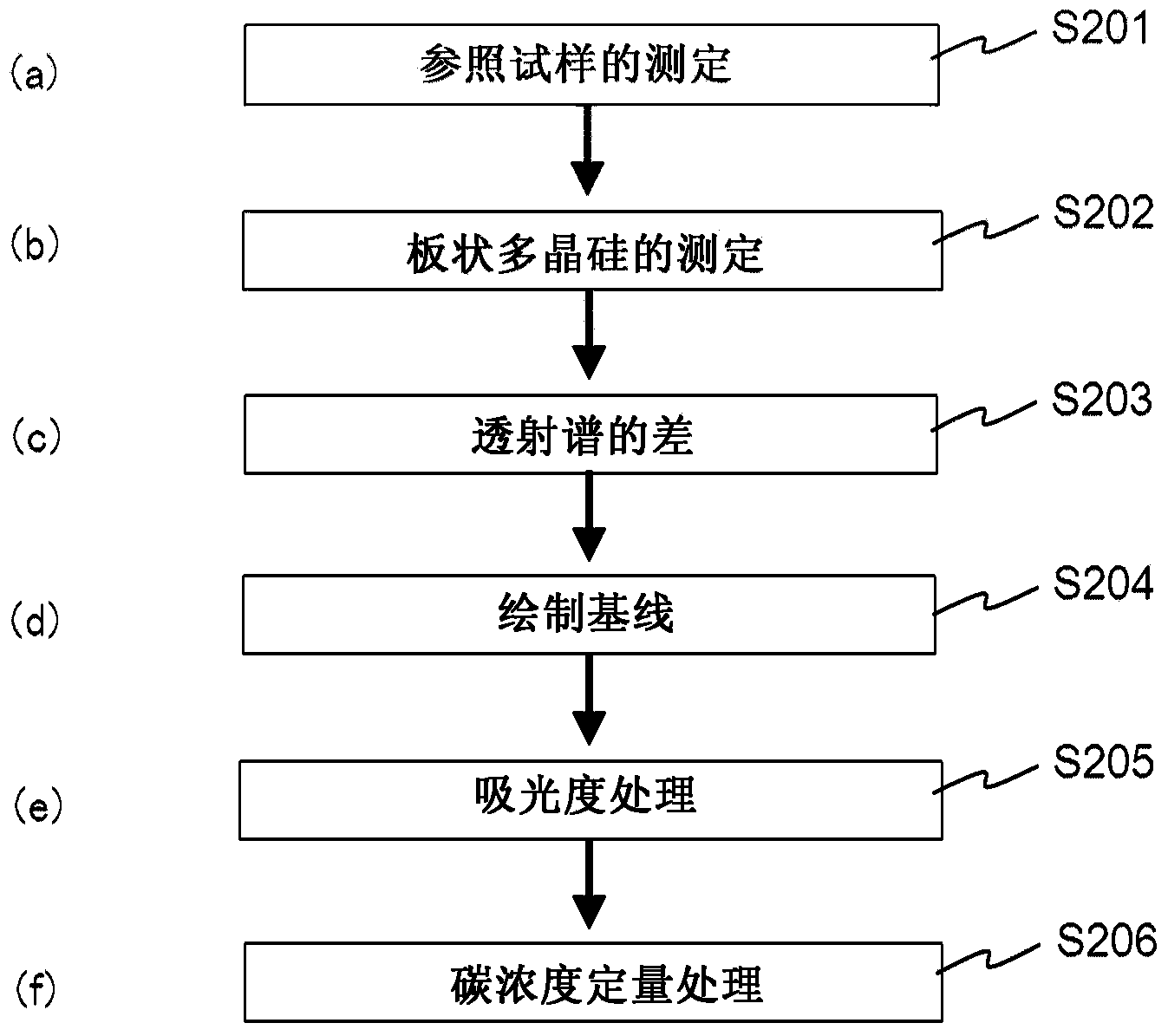

[0051] The transmission spectra of these samples were measured, and the carbon concentration of each sample was determined. As a result, the plate-shaped FZ single crystal silicon was 0.08758 ppma, and the plate-shaped polycrystalline silicon with thicknesses of 2.006 mm and 2.477 mm were -0.06909 ppma and 0.56866 ppma, respectively.

[0052] A second calibration curve was prepared from the carbon concentration value -0.06909ppma of plate-shaped polysilicon with a thickness of 2.006mm and the carbon concentration value of 0.56866ppma in plate-shaped polysilicon with a thickness of 2.477mm, and the thickness of the second calibration curve was obtained as 2.00±0.01mm Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com