Process for preparing high-specific surface area composite pore structure coal-based activated carbon by using low dosage of KOH

A technology with high specific surface area and composite pores, which is applied in the direction of carbon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of production equipment corrosion, production cost increase, and high price of petroleum coke, so as to save costs, improve utilization efficiency, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

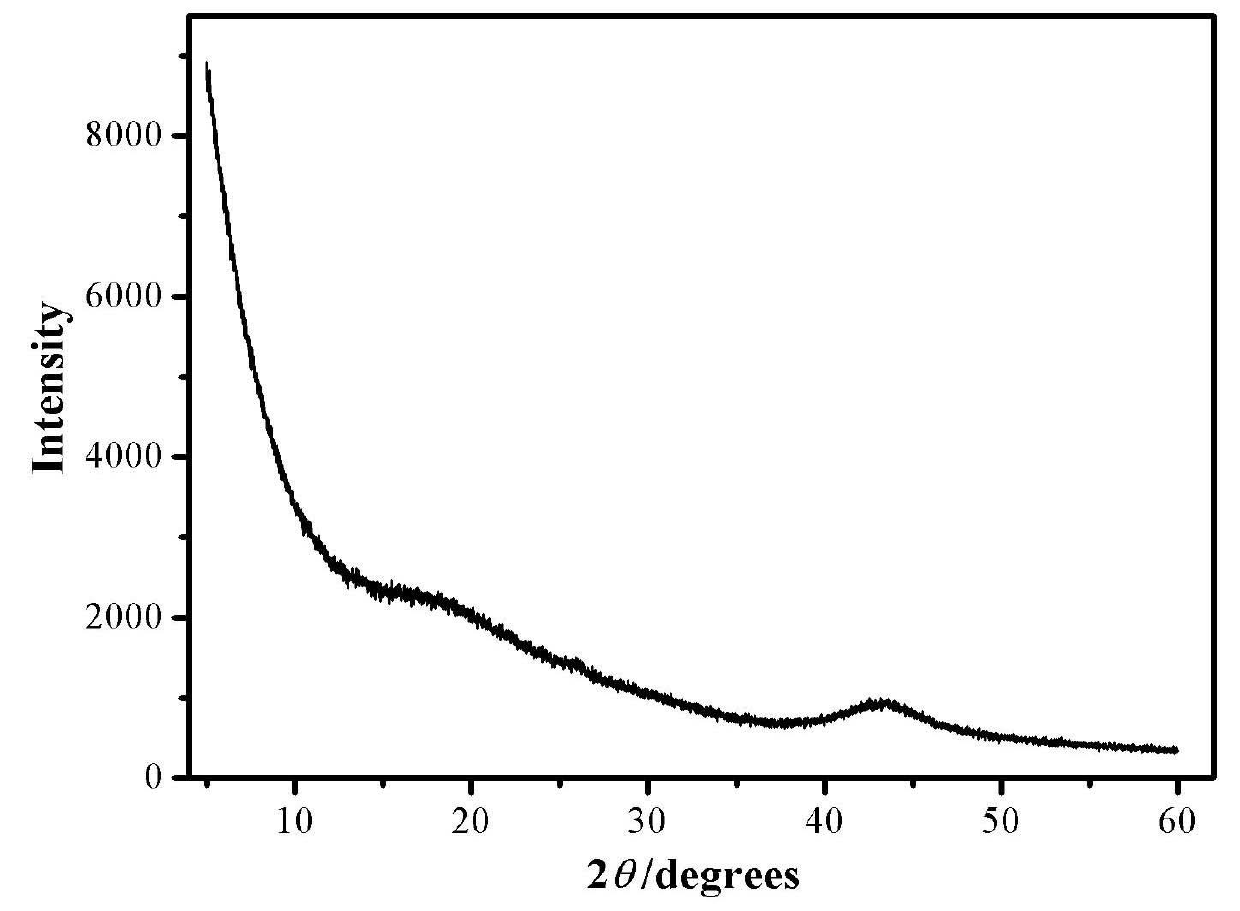

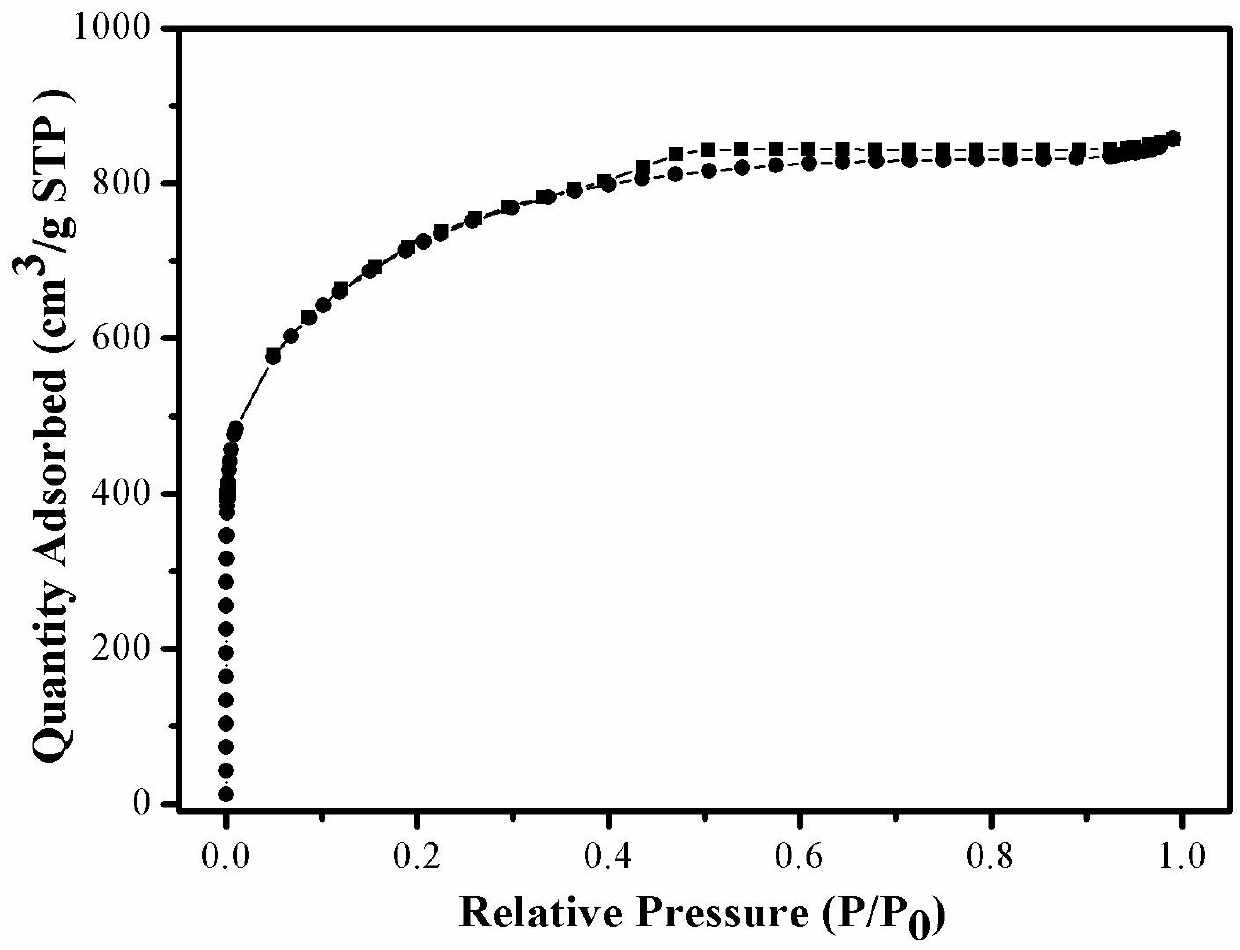

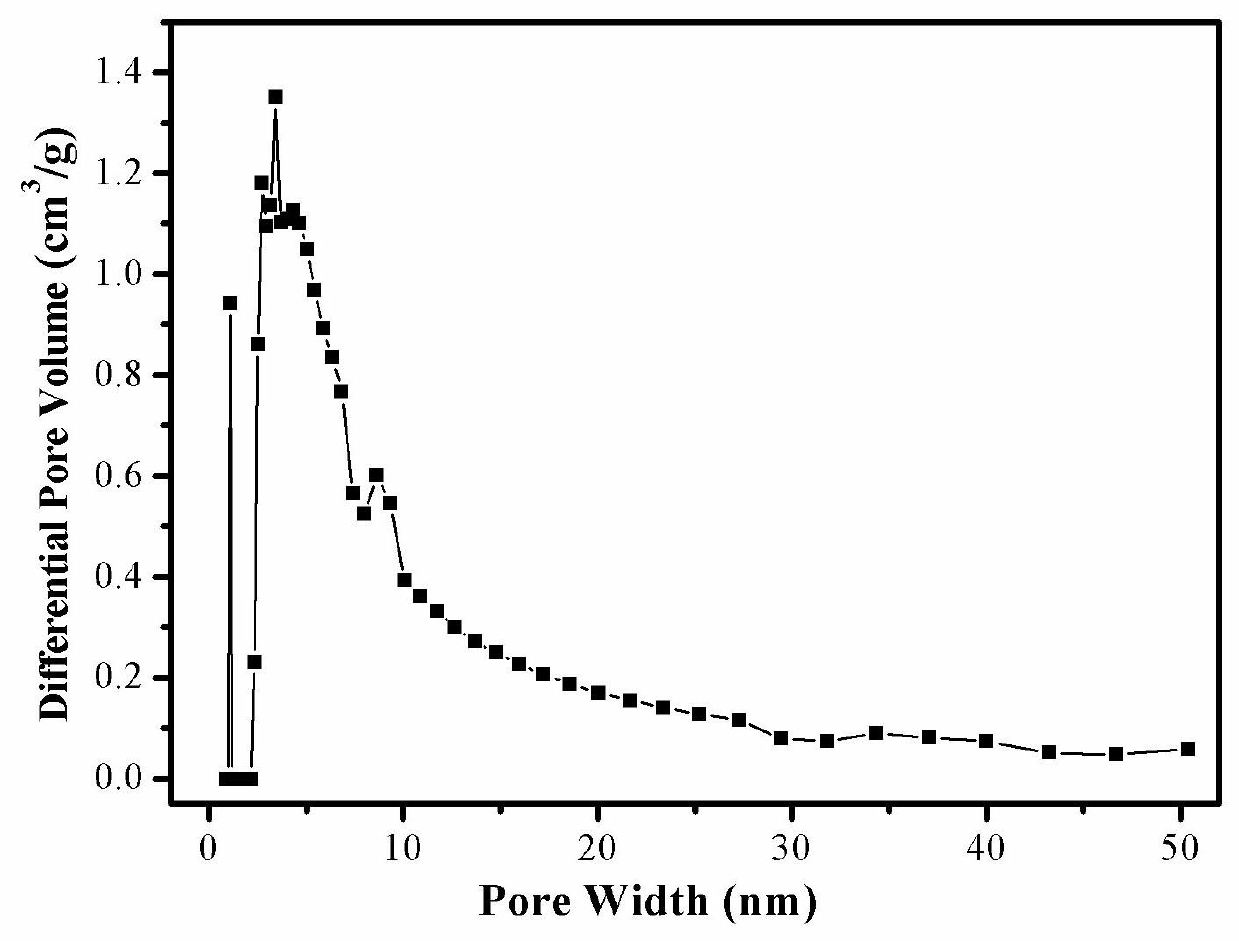

[0016] Embodiment 2: The coal sample in Liushuanggou, Xinjiang is crushed, sieved to 150-200 mesh, the sieved coal sample and KOH are mixed uniformly by solid phase grinding in the ratio of 1:0.6, and the mixture is mixed under nitrogen (N 2 ) in an atmosphere for carbonization and activation (increase the temperature at a rate of 6 °C / min to 800 °C, keep the temperature for 30 min, then increase the rate of temperature at 5 °C / min to 1100 °C, and keep the temperature for 30 min). After cooling to room temperature, take out the activated product, first Wash with boiling water, then wash with dilute hydrochloric acid, and finally wash with water to remove acid. After drying, the sample can be obtained. The yield of the sample is 37.6%, and the BET specific surface area of the sample is 1579 m 2 / g, Langmuir specific surface area is 1866m 2 / g, the pore volume is 0.773cm 3 / g, the mesopore volume is 0.449cm 3 / g, the pore structure is micropore-mesoporous composite pore str...

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com