Coal-water slurry slurrying system and method for coal chemical industry

A technology for coal-water slurry and coal chemical industry, applied in the field of coal chemical industry, can solve the problems of affecting the stability of slurry production, reducing the service life, and covering a large area, so as to provide stability of slurry production, simplify equipment, and reduce floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

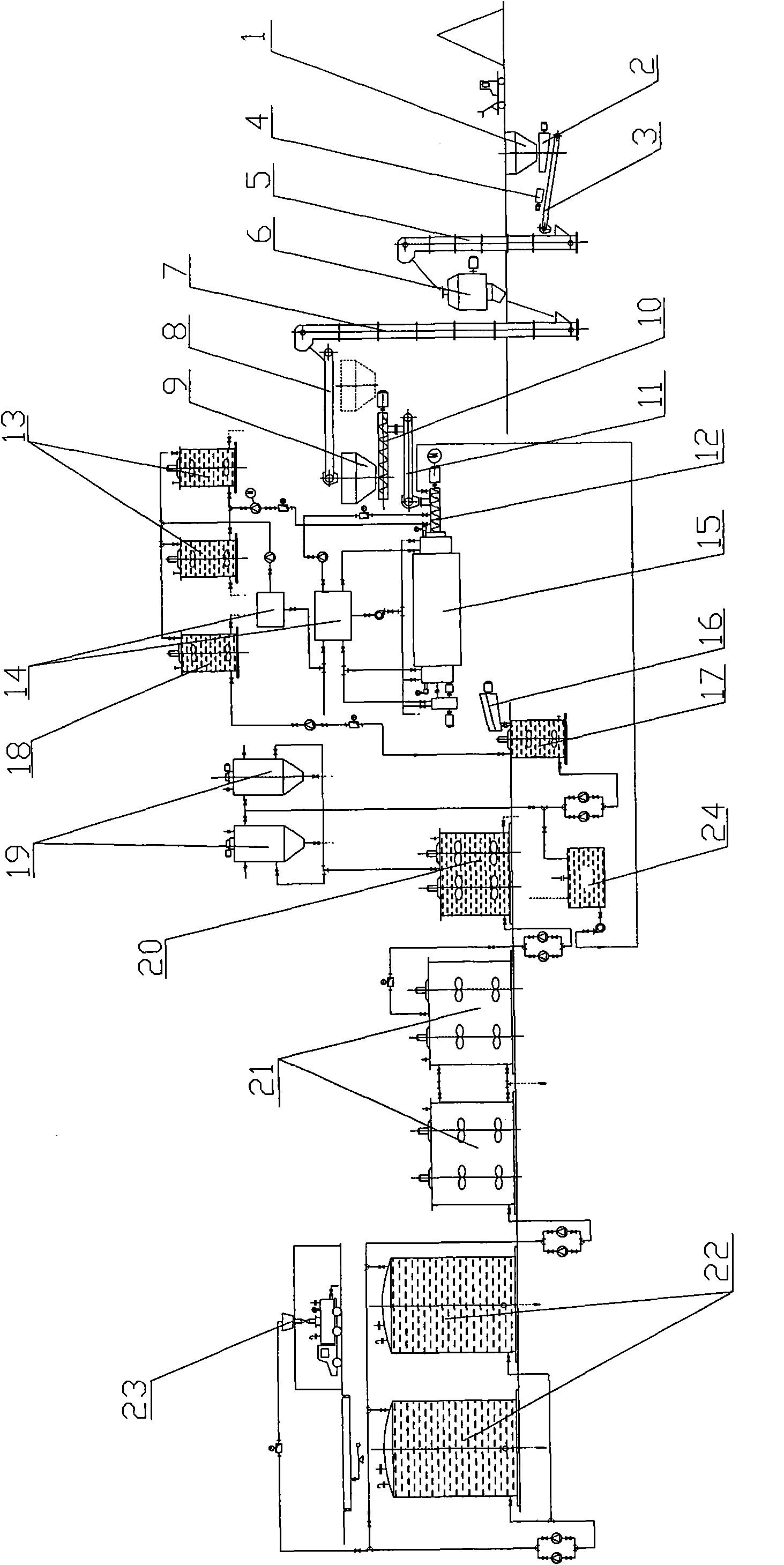

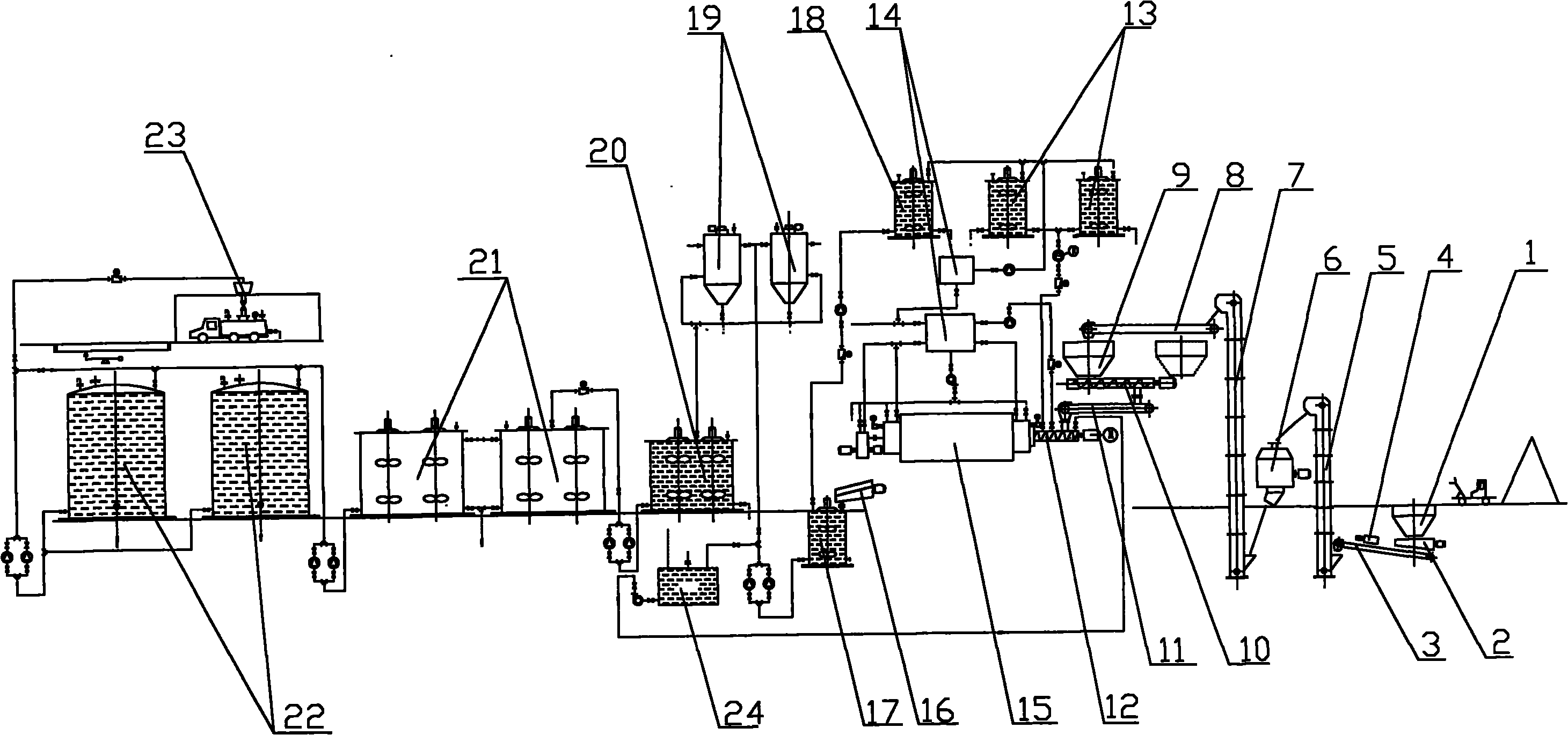

[0023] see figure 1 , the present invention relates to a system and method for making water-based coal slurry in the coal chemical industry. The system includes a raw material bin 1, a vibrating feeder 2, a belt conveyor-3, a magnetic separator 4, a bucket elevator-5, Crusher 6, bucket elevator II 7, belt conveyor II 8, intermediate warehouse 9, screw conveyor 10, belt weighing machine 11, coal water slurry screw feeder 12, dispersant dilution tank 13, water tank 14, Coal water slurry special mill 15, vibrating screen 16, coal water slurry buffer tank 17, stabilizer dilution tank 18, coal water slurry filter 19, stability adjustment treatment barrel 20, homogeneous aging tank 21, slurry storage tank 22 , slurry station 23 and waste pond 24;

[0024] The feeding place of the raw material bin 1 is provided with several grilles, the bottom outlet of the raw material bin 1 is facing the feeding end of the vibrating feeder 2, and the discharging end of the vibrating feeder 2 is fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com