High-efficiency jet nozzle capable of continuously regulating position of jet pipe

A jet nozzle and jet nozzle technology, applied in the field of jet pumps, can solve problems such as waste of manpower and material resources, and achieve the effects of saving processing costs, optimizing efficiency, and minimizing operation and maintenance and equipment maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

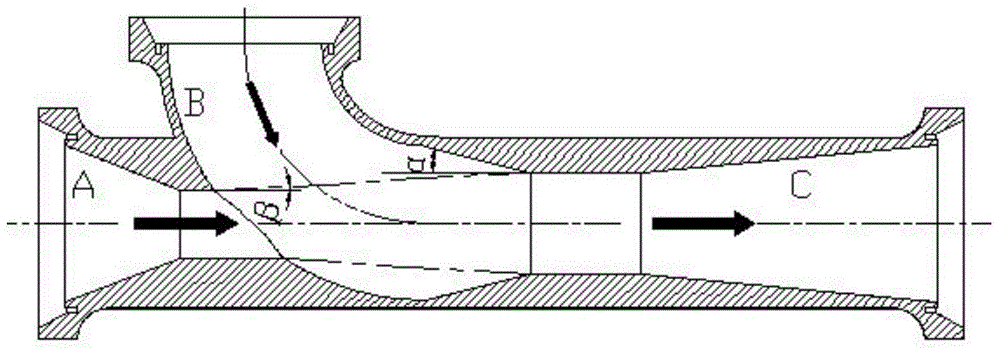

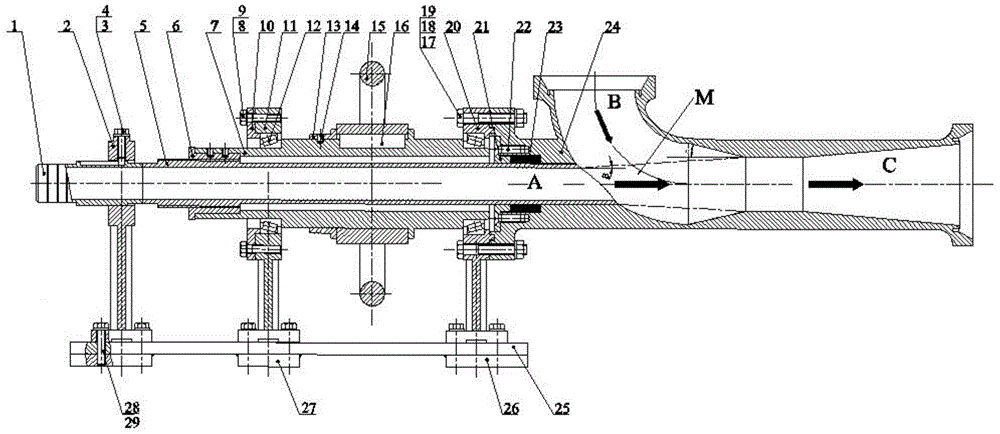

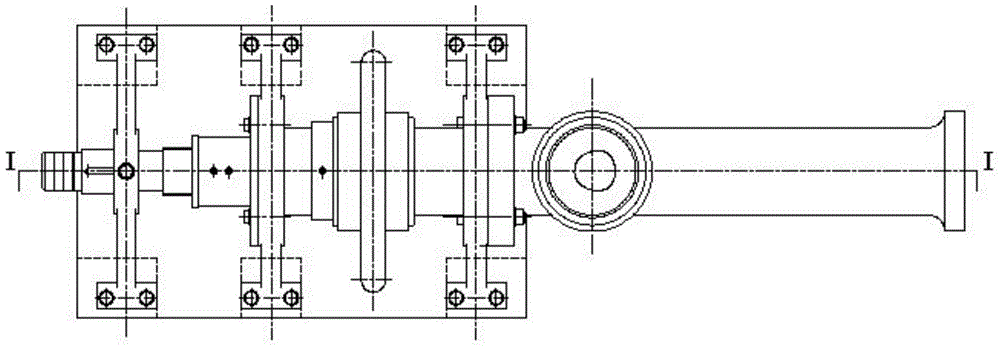

[0034] A high-efficiency jet nozzle that can continuously adjust the position of the jet nozzle to attach figure 1 The direction shown shows that the main body of the jet nozzle is a circular tube structure, and the left end of the jet nozzle is the input end of the jet nozzle, which is connected to the booster chamber A, and the inside of the booster chamber A is a conical inner cavity with a large left end and a small right end , the inside of the jet nozzle at the right end of the pressurization chamber is a mixing chamber M with a larger space, and the upper end of the corresponding jet nozzle above is radially formed with a solid powder feeding port; the inner cavity of the right part of the jet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com