Production method of semi-hydrated gypsum powder

A production method and technology of gypsum powder, which is applied in the production field of hemihydrate gypsum powder, can solve the problems of huge equipment investment, large installed capacity, and large wind resistance, and achieve low construction and operation costs, reasonable structural layout, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

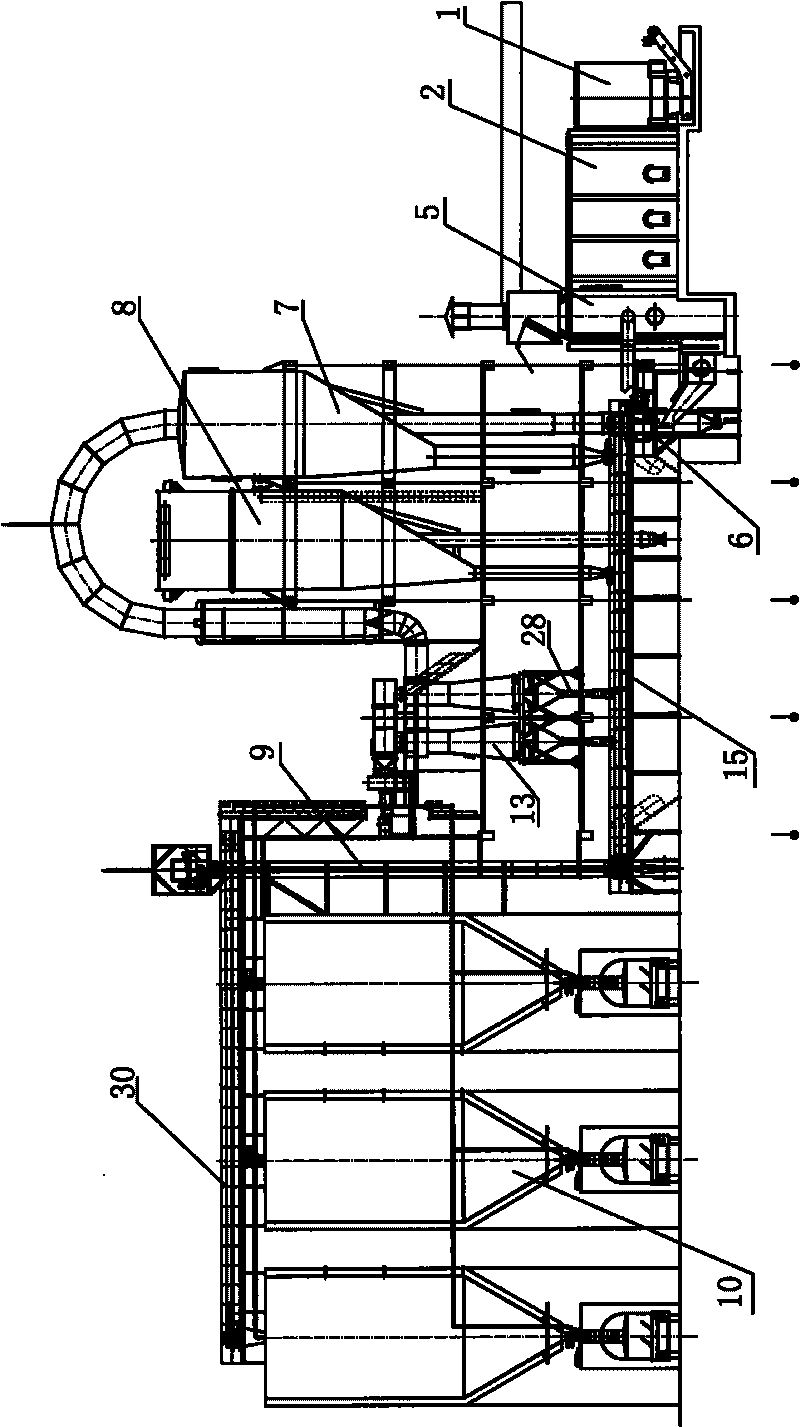

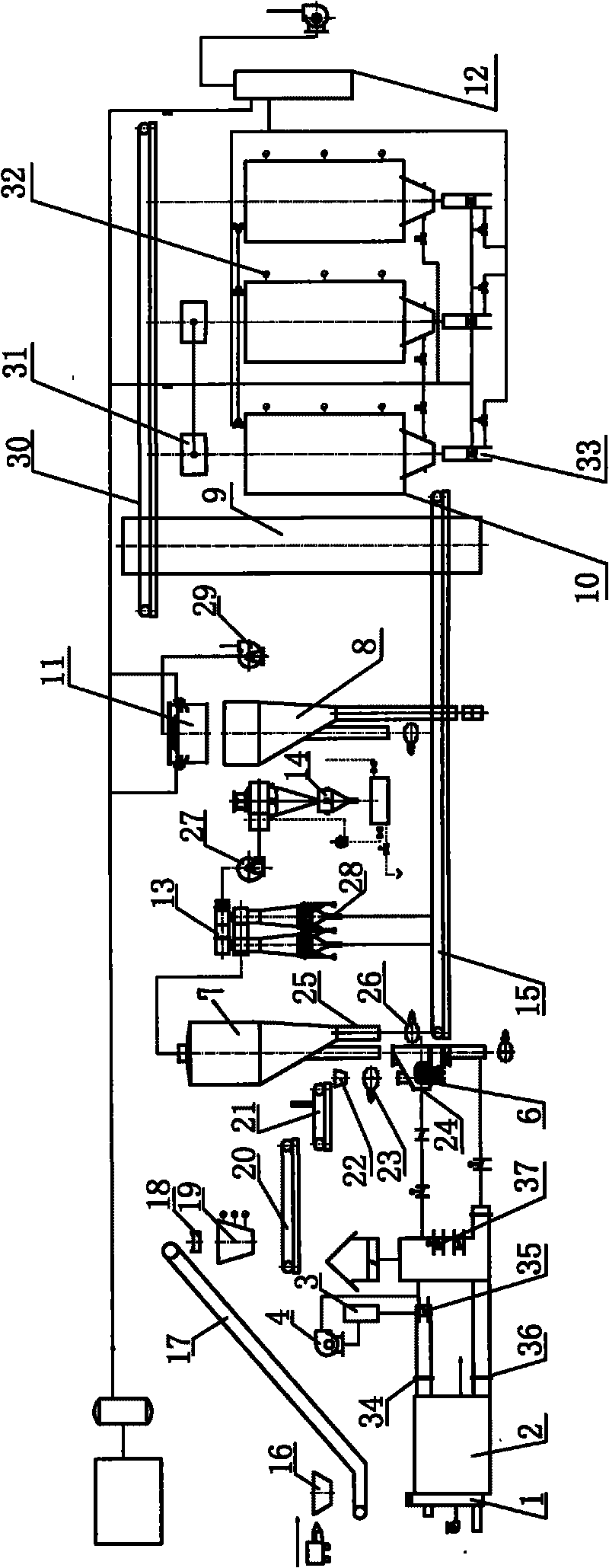

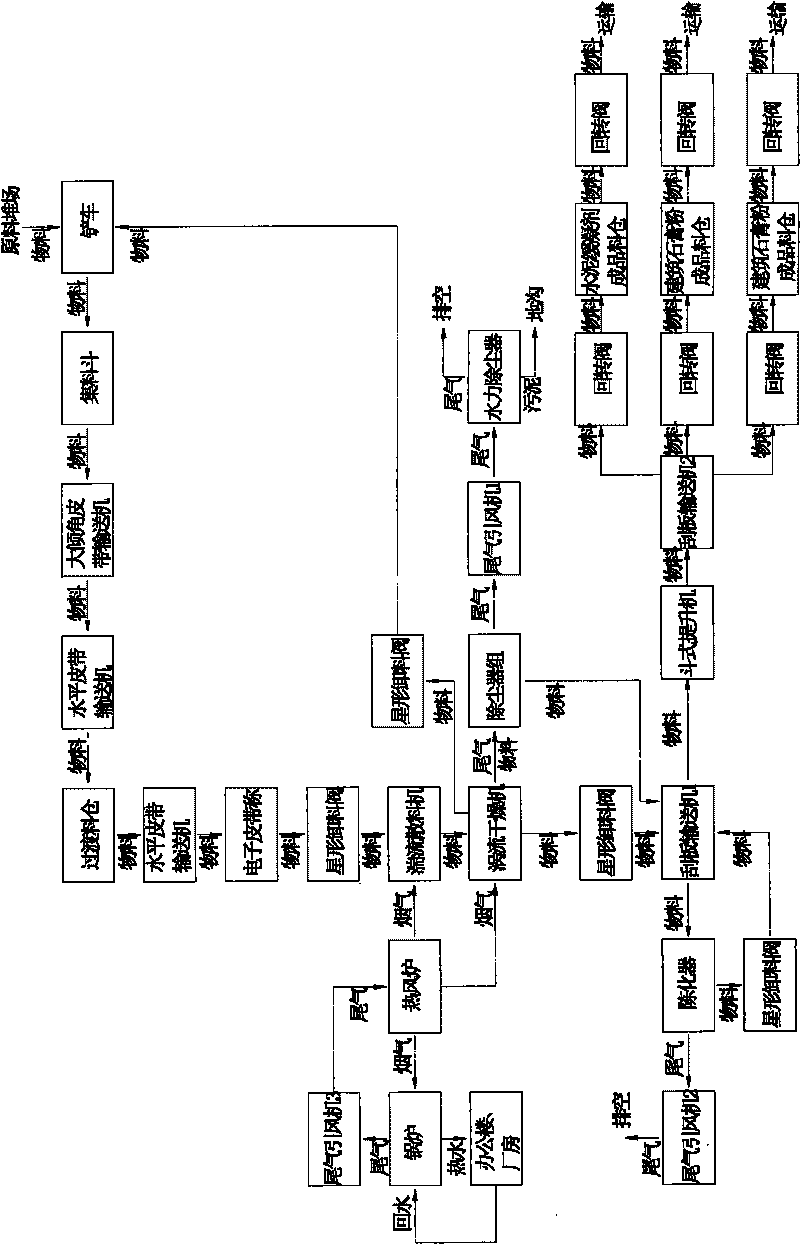

[0023] A production method of hemihydrate gypsum powder, comprising a raw material preheating and conveying system, drying and calcining of gypsum powder, conditioning and storage, a hot air supply system and a dust removal system.

[0024] The equipment used includes direct-fired coal-fired hot blast stove 1, hot air temperature at 200-750°C, high-temperature purification room 2, heat exchanger 3, induced draft fan 4, air mixing chamber 5, turbulent flow dispersing dryer 6, eddy current sedimentation drying machine 7, aging device 8, bucket elevator 9 and three tempering storage bins 10. The first bag filter 11, the second bag filter 12, the cyclone dust collector 13, the hydraulic dust collector 14, the first horizontal scraper conveyor 15, the collecting hopper 16, the large angle belt conveyor 17, and the first horizontal conveyor 18 , Transition silo 19 with material level meter, second horizontal conveyor 20, electronic belt scale 21 and lower hopper 22.

[0025] When p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com