Device and method for carrying out granulation treatment and residual heat utilization on liquid-state furnace slag

A slag and granulation technology is applied in the field of liquid slag granulation treatment and waste heat utilization devices, and achieves the effects of easy recycling, uniform slag particle size and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

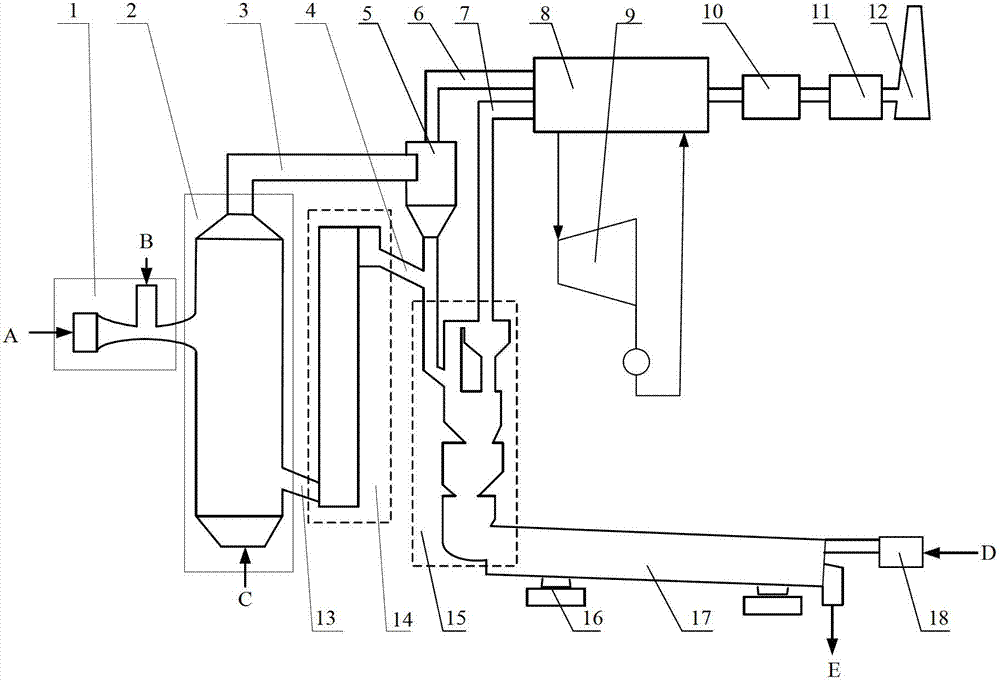

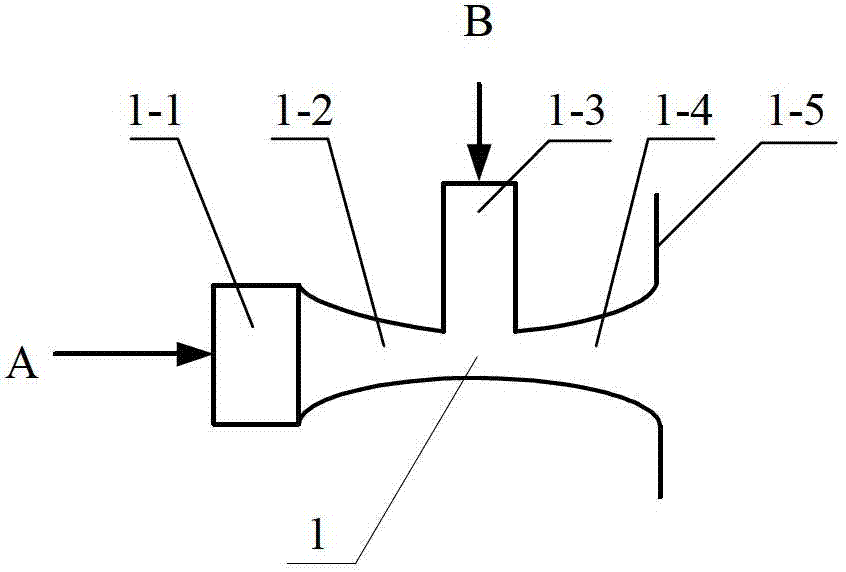

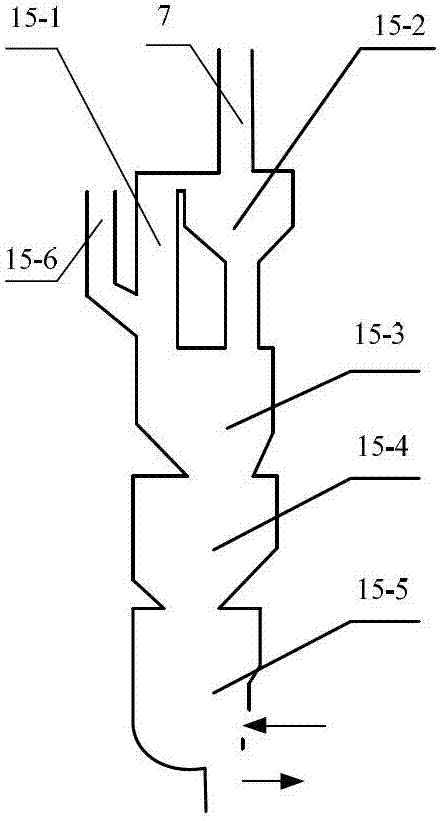

[0039] This embodiment provides a liquid slag granulation treatment and waste heat utilization device, connected as figure 1 As shown, it includes a granulation assembly 1, a slag storage tank 2, an exhaust gas separator 5, a waste heat boiler 8, a steam turbine 9, a dust collector 10, an induced draft fan 11, a chimney 12, a bucket elevator 14, and a gas-solid separation cooling chamber 15 , a converter 17, a blower 18; the granulation assembly 1 is provided with a high-pressure air or high-pressure water inlet A, a liquid slag inlet B and a granulated slag outlet, the granulated slag outlet is connected to the slag storage tank 2, and the bottom of the slag storage tank 2 is provided with Air inlet C, the lower part of the slag storage tank 2 is connected to the bucket elevator 14 through the high-temperature solid slag discharge pipe 13, the top of the slag storage tank 2 is connected to the tail gas separator 5 through the connecting pipe 3 of the granulated crude tail gas,...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that the structure of the gas-solid separation cooling chamber 15 is different. The gas-solid separation cooling chamber 15 of the present embodiment is composed of a riser 15-8, a three-stage gas-solid separation cooler 15- 7. The secondary gas-solid separation cooler 15-10, the primary gas-solid separation cooler 15-11 and the standpipe 15-9; the inlet of the standpipe 15-9 is connected to the lower part of the tail gas separator 5 and the top of the bucket elevator 14 , the outlet of the riser 15-6 is connected to the riser 15-8, the upper part of the riser 15-8 is connected to the third-stage gas-solid separation cooler 15-7, the lower part is connected to the second-stage gas-solid separation cooler 15-10, and the third-stage gas-solid separation cooler 15-10 is connected to the lower part of the riser 15-8 The upper part of the separation cooler 15-7 is connected to the high-temperature air connecting pipe ...

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that the structure of the gas-solid separation cooling chamber 15 is different. Bed 15-14, gas-solid separation cooler 15-15, air distribution plate 15-16 and blanking connecting pipe 15-17; the inlet of feeding riser 15-12 is connected to the lower part of tail gas separator 5 and bucket elevator 14 At the top, the baffle bed 15-14 is provided with multi-layer air distribution plates 15-16 from top to bottom, the outlet of the feed riser 15-12 is connected to the top air distribution plate 15-16, and the connection is provided with a baffle The plate 15-13, the upper part of the baffle bed 15-14 is connected to the gas-solid separation cooler 15-15, the upper part of the gas-solid separation cooler 15-15 is connected to the high-temperature air connecting pipe 7, and the lower part is connected to the air distribution plate 15-16, and the baffle The lower part of the beds 15-14 is connected to the converter 17....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com