Metal silicon powder production process and device

A technology of metal silicon powder and preparation process, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of long residence time, impact on product quality, and large screen wear, so as to reduce the content of finished powder and improve the quality of finished products at one time. rate, reducing the effect of feed particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

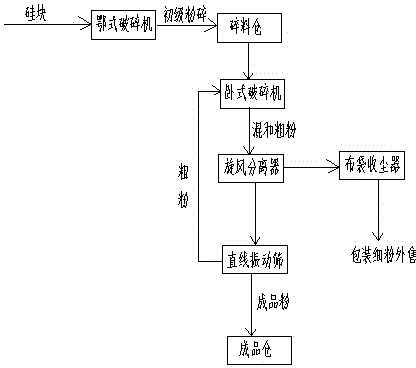

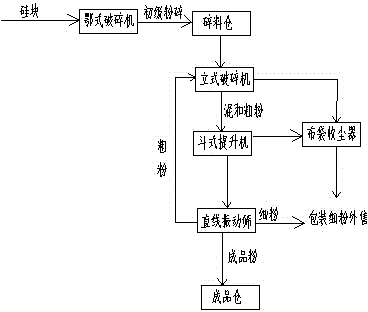

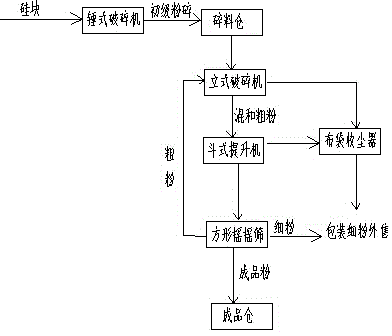

[0033] Such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the process steps of the present invention are as follows: first, the silicon block is primary pulverized by a hammer crusher, enters the crushed material bin through the first bucket elevator, and then is sent into a vertical pulverizer for grinding and pulverization; the pulverized material is mixed and coarsely The powder is sent to the square swinging sieve through the second bucket elevator for screening, the finished powder sieved to the lower part of the square swinging sieve is stored in the finished product warehouse, and the coarse powder retained in the upper part of the square swinging sieve is sent back to the vertical sieve through the third bucket elevator. Type pulverizer for re-crushing; the fine powder of the pulverized material is collected by the bag vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com