Efficient, energy-saving and environmentally-friendly waste activated carbon regeneration method

A waste activated carbon, high-efficiency and energy-saving technology, which is applied in the direction of separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problem of single treatment method and achieve high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

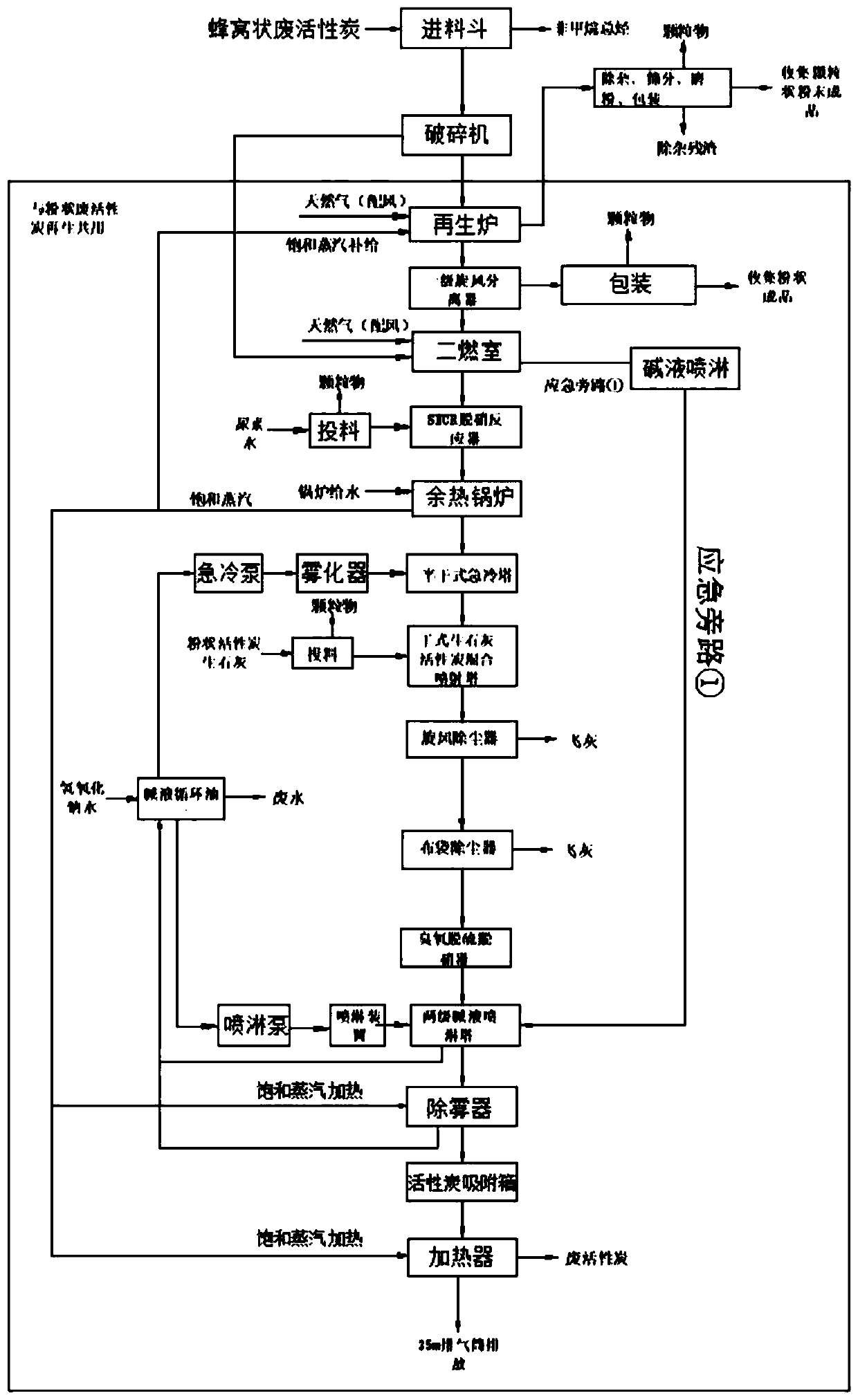

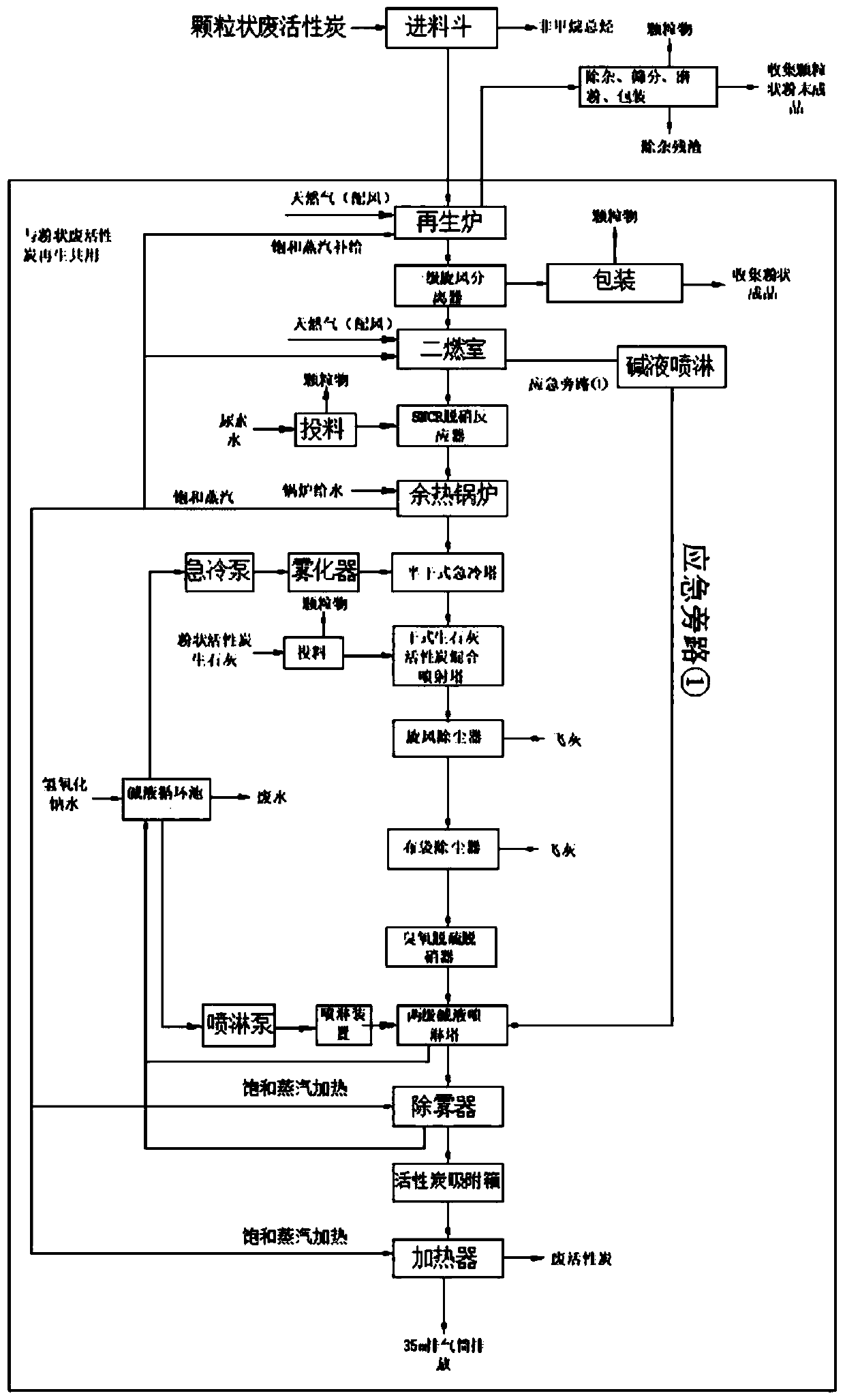

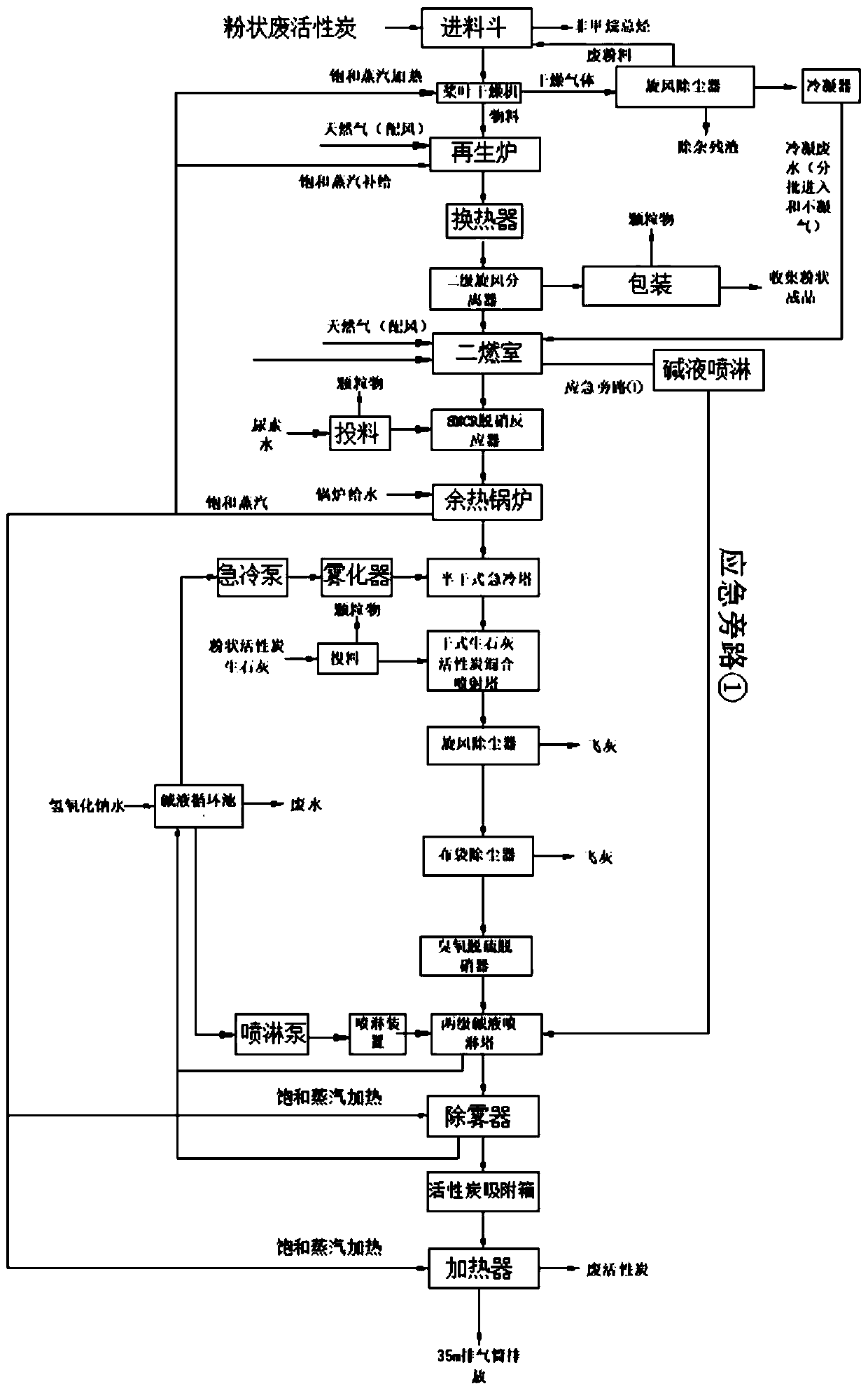

[0036] The following is attached Figure 1-5 The present invention is described in further detail.

[0037] A kind of highly efficient, energy-saving and environment-friendly waste activated carbon regeneration method, such as Figure 1-5 As shown, it includes feed system, regeneration system, discharge system, combustion system, flue gas purification system and waste heat recovery system. Step 1, feed system, put the materials to be regenerated into the feed hopper, and the materials are lifted by the bucket Machine, scraper machine into the airtight silo;

[0038] Step 2. Regeneration system. The material in the closed silo in step 1 is sent to the regeneration furnace through the screw feeder for regeneration, and a small amount of air and water vapor are introduced, and the exhaust gas adsorbed by the spent activated carbon is decomposed at high temperature and combined with oxygen The reaction produces water vapor and carbon dioxide gas, and the regenerated activated ca...

Embodiment 1

[0070] A kind of highly efficient, energy-saving and environment-friendly waste activated carbon regeneration method, such as Figure 1-3 As shown, it includes feed system, regeneration system, discharge system, combustion system, flue gas purification system and waste heat recovery system. Step 1, feed system, put the materials to be regenerated into the feed hopper, and the materials are lifted by the bucket Machine, scraper machine into the airtight silo;

[0071] Step 2. Regeneration system. The material in the closed silo in step 1 is sent to the regeneration furnace through the screw feeder for regeneration, and a small amount of air and water vapor are introduced, and the exhaust gas adsorbed by the spent activated carbon is decomposed at high temperature and combined with oxygen The reaction produces water vapor and carbon dioxide gas, and the regenerated activated carbon is deposited at the bottom of the regeneration furnace, and after cooling, it is sent to a closed ...

Embodiment 2

[0104] A kind of highly efficient, energy-saving and environment-friendly waste activated carbon regeneration method, such as Figure 4-5 As shown, it includes feed system, regeneration system, discharge system, combustion system, flue gas purification system and waste heat recovery system. Step 1, feed system, put the materials to be regenerated into the feed hopper, and the materials are lifted by the bucket Machine, scraper machine into the airtight silo;

[0105] Step 2. Regeneration system. The material in the closed silo in step 1 is sent to the regeneration furnace through the screw feeder for regeneration, and a small amount of air and water vapor are introduced, and the exhaust gas adsorbed by the spent activated carbon is decomposed at high temperature and combined with oxygen The reaction produces water vapor and carbon dioxide gas, and the regenerated activated carbon is deposited at the bottom of the regeneration furnace, and after cooling, it is sent to a closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com