Using method of full-automatic production line of slices

A fully automatic, production-line technology, applied in the directions of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of no intelligent or automatic production line, high product cost, and reduced living space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

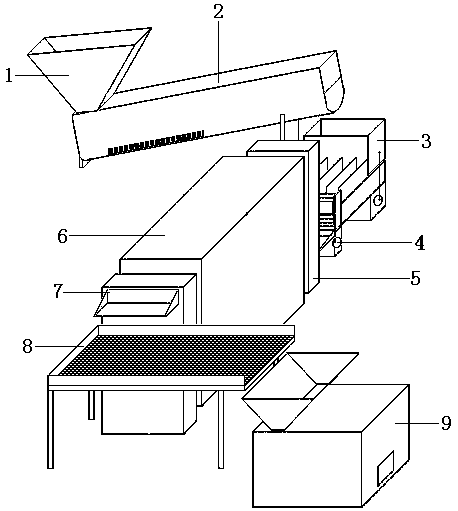

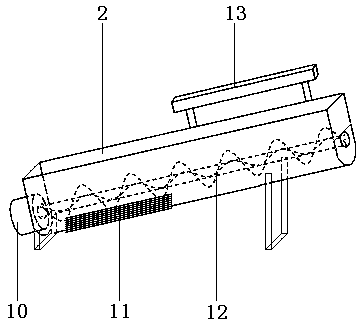

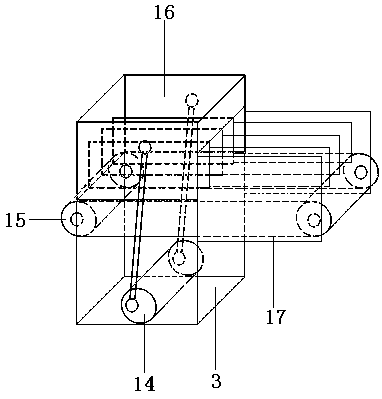

[0025] A fully automatic production line for slicing: including material box 1, ultrasonic water tank 2, shaping machine shell 3, slicing machine bracket 4, first-level hoist box body 5, hot air dryer box body 6, second-level hoist machine box body 7, track type separator Screening 8, moisture-proof storage box 9, adjustable speed reduction motor 10, ultrasonic generator 11, screw propeller 12, high-pressure nozzle 13, eccentric shaft motor of shaping machine 14, roller motor of shaping machine 15, hopper of shaping machine 16, conveyor belt 17. Slicer eccentric shaft motor 18, reciprocating cutter 19, drum traction motor 20, primary hoist drum motor 21, primary hoist belt 22, dry heating tube 23, dryer drum motor 24, circulation fan 25. The secondary hoist drum motor 26, the secondary hoist belt 27, the eccentric shaft deceleration motor 28, the digital control box 29, the power signal line 30, the material box 1 is connected to the ultrasonic water tank 2, and the ultrasonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com