Low-loss large-effective area single mode fiber and manufacturing method thereof

An effective area, single-mode fiber technology, used in cladding fibers, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of increasing the nonlinearity of communication systems, increasing fiber attenuation, and large bending losses, and reducing optical power. Density, reducing nonlinearity, increasing the effect of effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

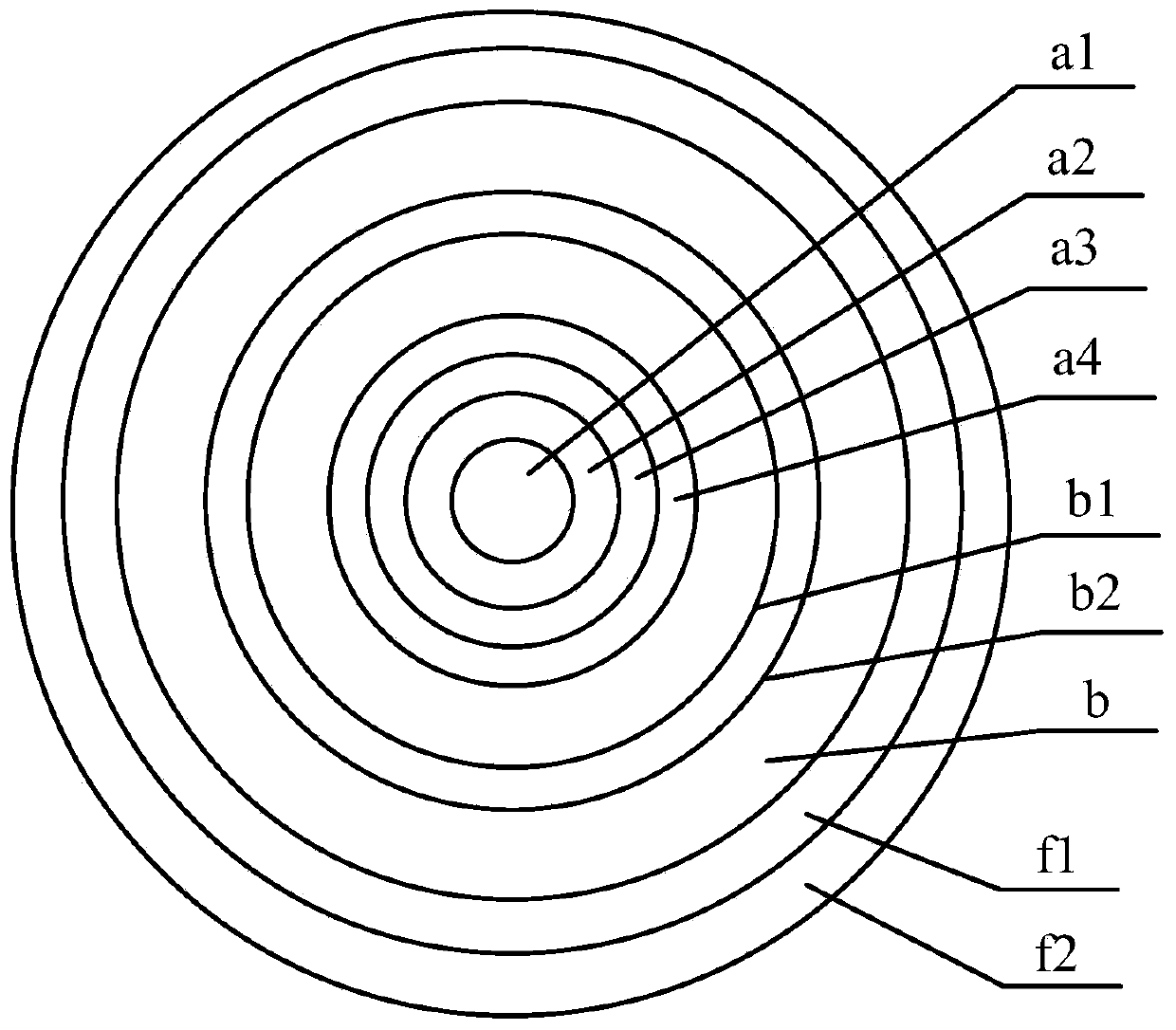

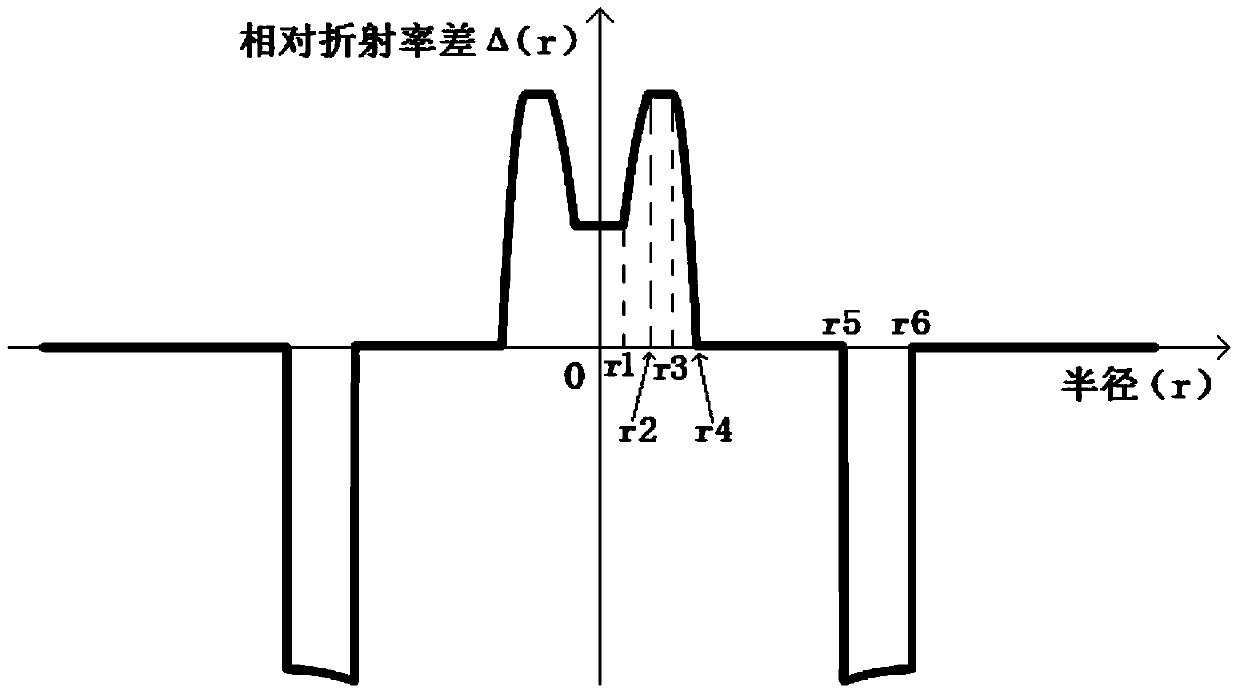

[0090] Silicon tetrachloride, germanium tetrachloride, high-purity oxygen, C 2 f 6 The mixed gas is passed into the deposition lathe (PCVD or VAD or MCVD or OVD), the total flow rate of the mixed gas is 13500ml / min, and the germanium-doped quartz glass core layer is generated under the high temperature of the hydrogen-oxygen flame, and the first core of the deposited core layer is area a 1 Relative refractive index difference Δ with quartz glass cladding b 1 (r) The change with the core radius r satisfies "Δ 1 (r)=c 1 "Relationship curve: 0≤r≤r 1 , r 1 = 1.50 μm, c 1 =0.10%, this part corresponds to figure 2 r in 1 The refractive index curve, forming figure 1 The first core region a in 1 ; the second core area a 2 Relative refractive index difference Δ with quartz glass cladding b 2 (r) The change with the core radius r satisfies "Δ 2 (r)=A×ln(r)+c 2 "Relationship curve: r 1 ≤r≤r 2 , r 2 =3.0μm, A=0.0022, c 2 =-0.00006, which corresponds to figure 2 r in ...

Embodiment 2

[0101] Silicon tetrachloride, germanium tetrachloride, high-purity oxygen, C 2 f 6 The mixed gas is passed into the deposition lathe (PCVD or VAD or MCVD or OVD), the total flow rate of the mixed gas is 12600ml / min, and the germanium-doped quartz glass core layer is generated under the high temperature of the hydrogen-oxygen flame, and the first core of the deposited core layer is area a 1 Relative refractive index difference Δ with quartz glass cladding b 1 (r) The change with the core radius r satisfies "Δ 1 (r)=c 1 "Relationship curve: 0≤r≤r 1 , r 1 = 1.0 μm, c 1 =0.07%, this part corresponds to figure 2 r in 1 The refractive index curve, forming figure 1 The first core region a in 1 ; the second core area a 2 Relative refractive index difference Δ with quartz glass cladding b 2 (r) The change with the core radius r satisfies "Δ 2 (r)=A×ln(r)+c 2 "Relationship curve: r 1 ≤r≤r 2 , r 2 =3.9μm, A=0.0019, c 2 =-0.00001, which corresponds to figure 2 r in 2...

Embodiment 3

[0109] Silicon tetrachloride, germanium tetrachloride, high-purity oxygen, C 2 f 6 The mixed gas is passed into the deposition lathe (PCVD or VAD or MCVD or OVD), the total flow rate of the mixed gas is 5000ml / min, and the germanium-doped quartz glass core layer is generated under the high temperature of the hydrogen-oxygen flame, and the first core of the deposited core layer is area a 1 Relative refractive index difference Δ with quartz glass cladding b 1 (r) The change with the core radius r satisfies "Δ 1 (r)=c 1 "Relationship curve: 0≤r≤r 1 , r 1 = 2.0 μm, c 1 =0.15%, this part corresponds to figure 2 r in 1 The refractive index curve, forming figure 1 The first core region a in 1 ; the second core area a 2 Relative refractive index difference Δ with quartz glass cladding b 2 (r) The change with the core radius r satisfies "Δ 2 (r)=A×ln(r)+c 2 "Relationship curve: r 1 ≤r≤r 2 , r 2 =3.0μm, A=0.0025, c 2 =-0.00010, which corresponds to figure 2 r in 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com