Composite telegraph pole/street lamp pole and manufacturing method of street lamp pole

A technology for composite materials and electric poles, which is applied in the field of composite material electric poles, street light poles and street light poles and their production, can solve the problems of poor bending resistance, etc., and achieve improved bending resistance, easy transportation and installation, and low weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to allow those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The utility poles and lampposts made of composite materials disclosed in this embodiment can completely replace the existing metal or cement utility poles and lampposts, and have the advantages of light weight, convenient transportation and installation, high strength and long service life.

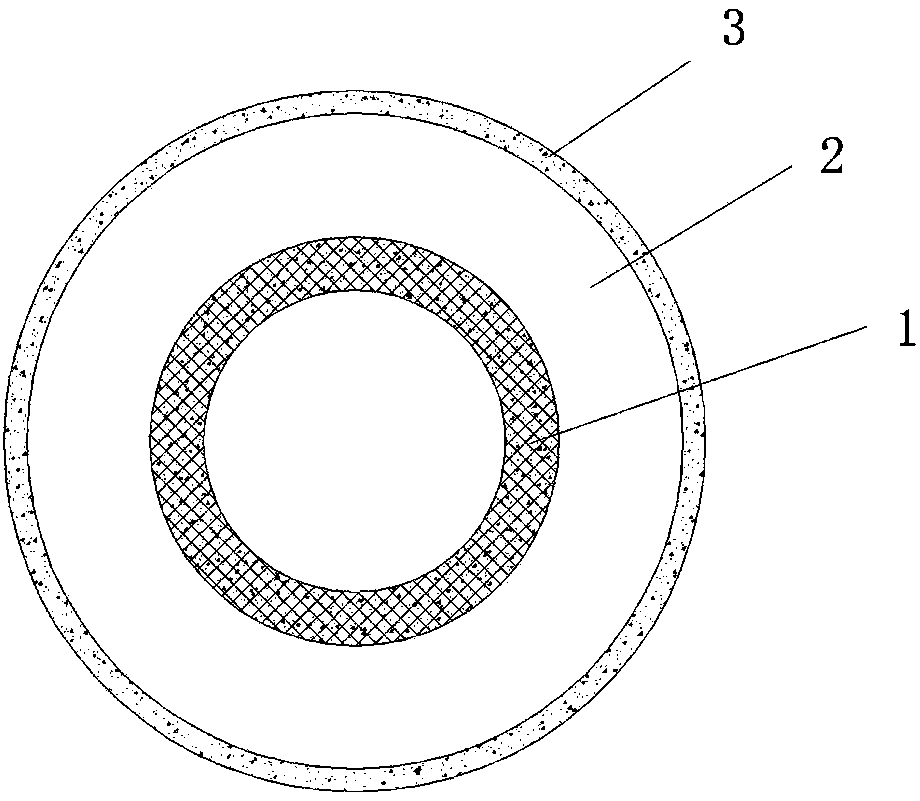

[0023] Such as figure 1 As shown, specifically, the utility poles and lampposts of composite materials disclosed in this scheme are in the same shape as the existing utility poles or lampposts as a whole, and are tubular, with a through hole with a large diameter at the lower end and a small diameter at the upper end in the middle, and a small diameter at the upper end on the outside. , The diameter of the lower end is large (when used as a street light pole, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com