Flexible carbon fiber nonwoven fabric

一种非织造布、碳纤维的技术,应用在非织造布、纤维处理、纺织品和造纸等方向,能够解决柔性不上足够、制造工序繁杂、断裂等问题,达到制造工序简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] (1) Preparation of electrospinning solution

[0100] Polyacrylonitrile (made by Mitsubishi Chemical Corporation, バレックス) (hereinafter referred to as PAN): 2.7

[0101] Phenolic resin (manufactured by Qunyei Chemical Industry Co., Ltd., PSK-2320) (hereinafter Ph): 3.0 Butoxytitanium (IV) (manufactured by Aldrich): 3.5

[0102] Dimethylformamide (manufactured by Wako Pure Chemical Industries, Ltd., special grade): 90.8

[0103] The mass ratio is mixed and dissolved to prepare an electrospinning solution.

[0104] (2) Electrospinning

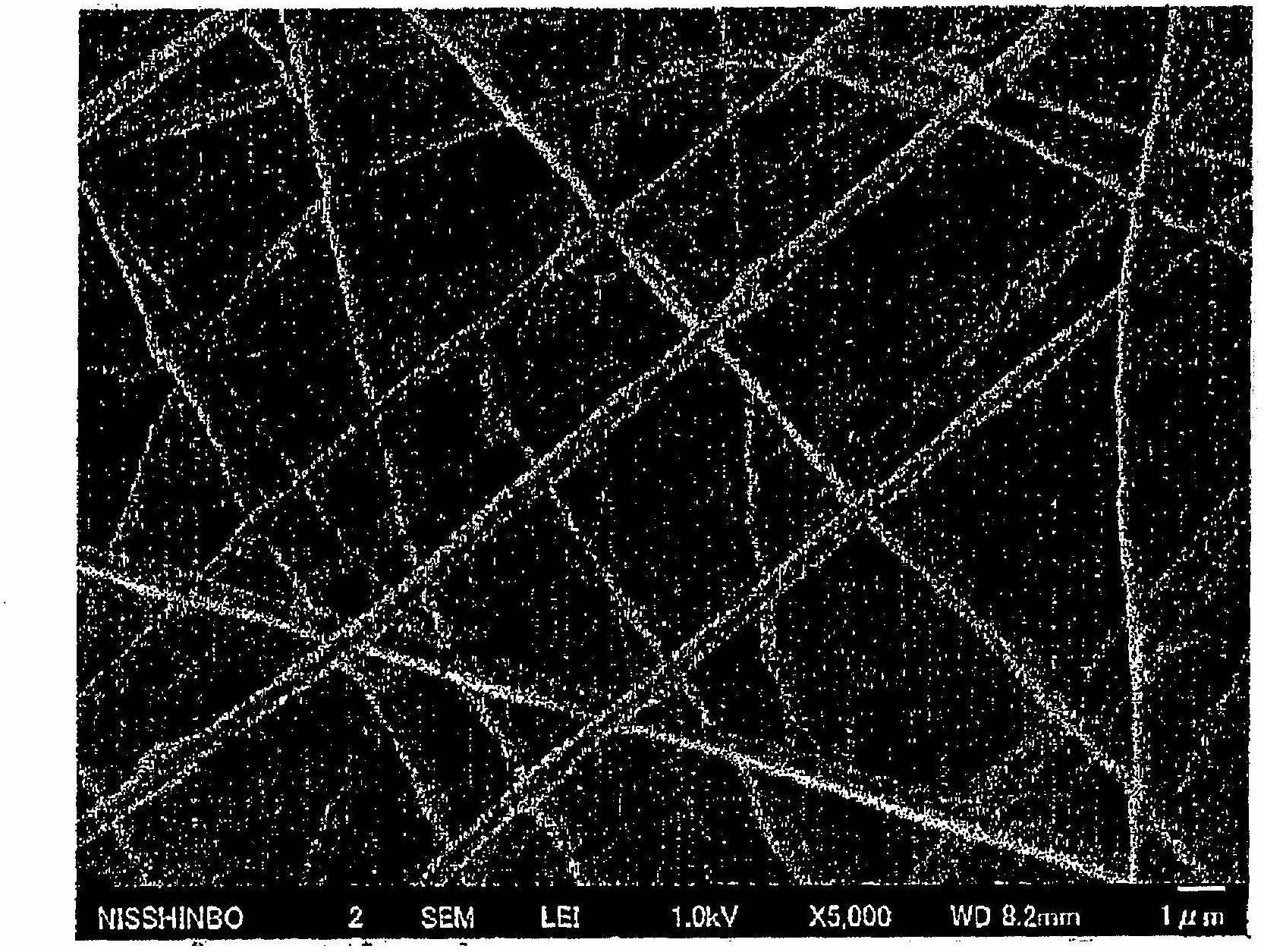

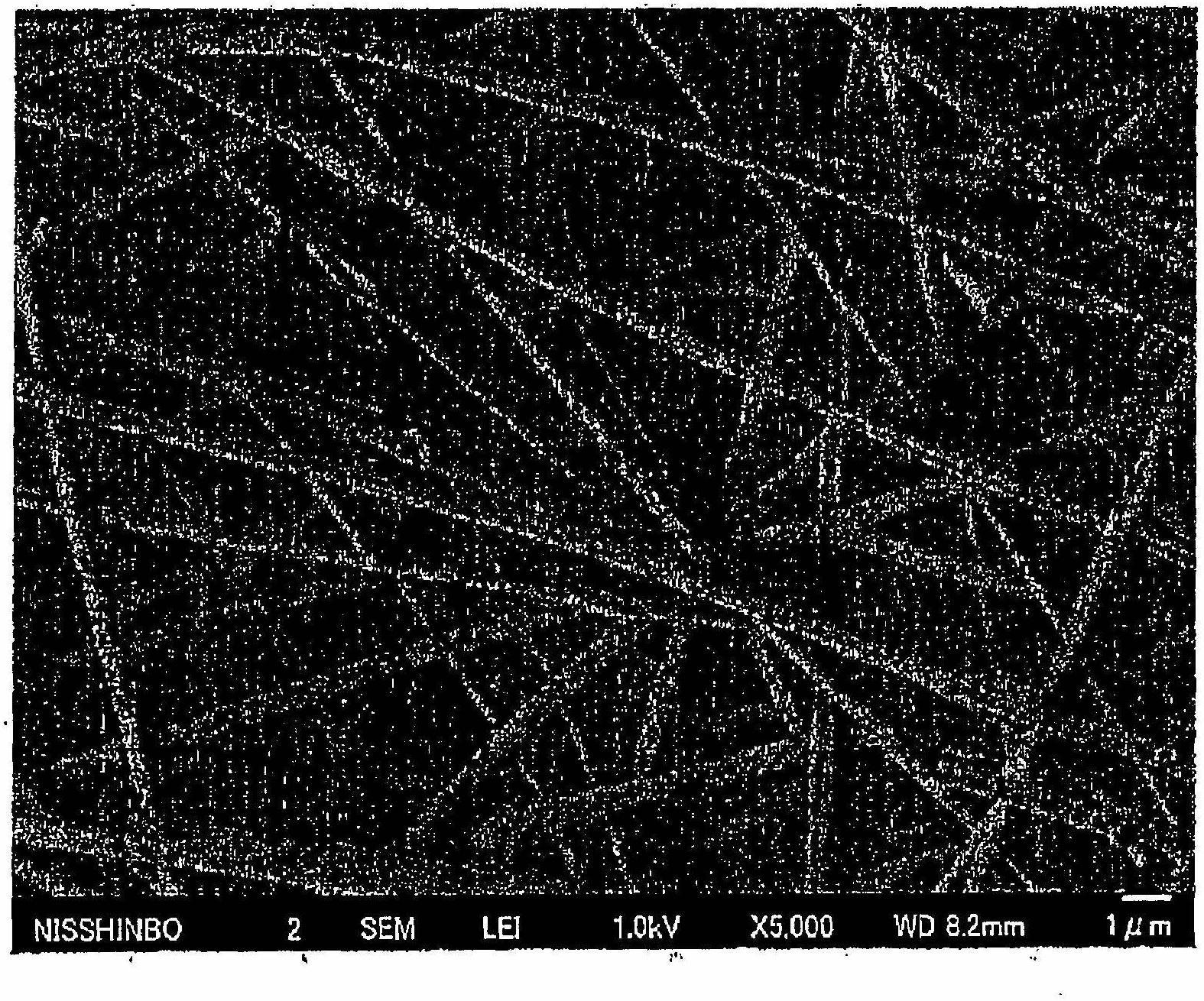

[0105] The electrospinning solution obtained above was fixed in an electrospinning device (manufactured by Fuyens Co., Ltd., ESP-2300). 25° C.) by electrospinning to obtain an ultrafine nonwoven fabric of long fibers with a laminated fiber diameter of about 600 nm.

[0106] (3) Curing (non-melting) treatment

[0107] The obtained ultrafine fiber nonwoven fabric was placed in an oven, heated from room temperature to 250° C. over 1.5 hours, ...

Embodiment 2

[0117] (1) Synthesis of polyacrylonitrile-polymethacrylic acid copolymer

[0118] 30.93 g of acrylonitrile (manufactured by Wako Pure Chemical Industries, Ltd.), 4.07 g of methacrylic acid (manufactured by Wako Pure Chemical Industries, Ltd.), and 300 mL of pure water were placed in a flask, and nitrogen gas was deaerated by bubbling (oxygen ), heated at 70° C., and fed while stirring a solution in which 100 mg of potassium persulfate (manufactured by Wako Pure Chemical Industries, Ltd.) was dissolved in 50 mL of pure water. After continuous stirring for 4 hours, the cloudy solution was concentrated and finally vacuum-dried to obtain about 20 g of polyacrylonitrile-polymethacrylic acid copolymer (hereinafter referred to as PAN-MAA).

[0119] (2) Preparation of electrospinning solution

[0120] PAN-MAA obtained from the above: 1.5

[0121] Ph: 1.5

[0122] Titanium(IV) tetrachloride (manufactured by Aldrich): 0.4

[0123] Dimethylformamide (manufactured by Wako Pure Chemica...

Embodiment 3

[0135] (1) Preparation of electrospinning solution

[0136] Take PAN: 15

[0137] Ph: 15

[0138] Titanium(IV) chloride (manufactured by Aldrich): 4.0

[0139] Dimethylformamide (manufactured by Wako Pure Chemical Industries, Ltd., special grade): 66

[0140] The mass ratio is mixed and dissolved to prepare an electrospinning solution.

[0141] (2) Electrospinning

[0142] Electrospinning was performed under the same conditions as in Example 1 to obtain a nonwoven fabric of ultrafine fibers laminated with long fibers having a fiber diameter of about 15 μm.

[0143] (3) Solidification and firing (carbonization) continuous treatment

[0144] Heat treatment was carried out under the same conditions as in Example 2 to obtain an ultrafine carbon fiber nonwoven fabric.

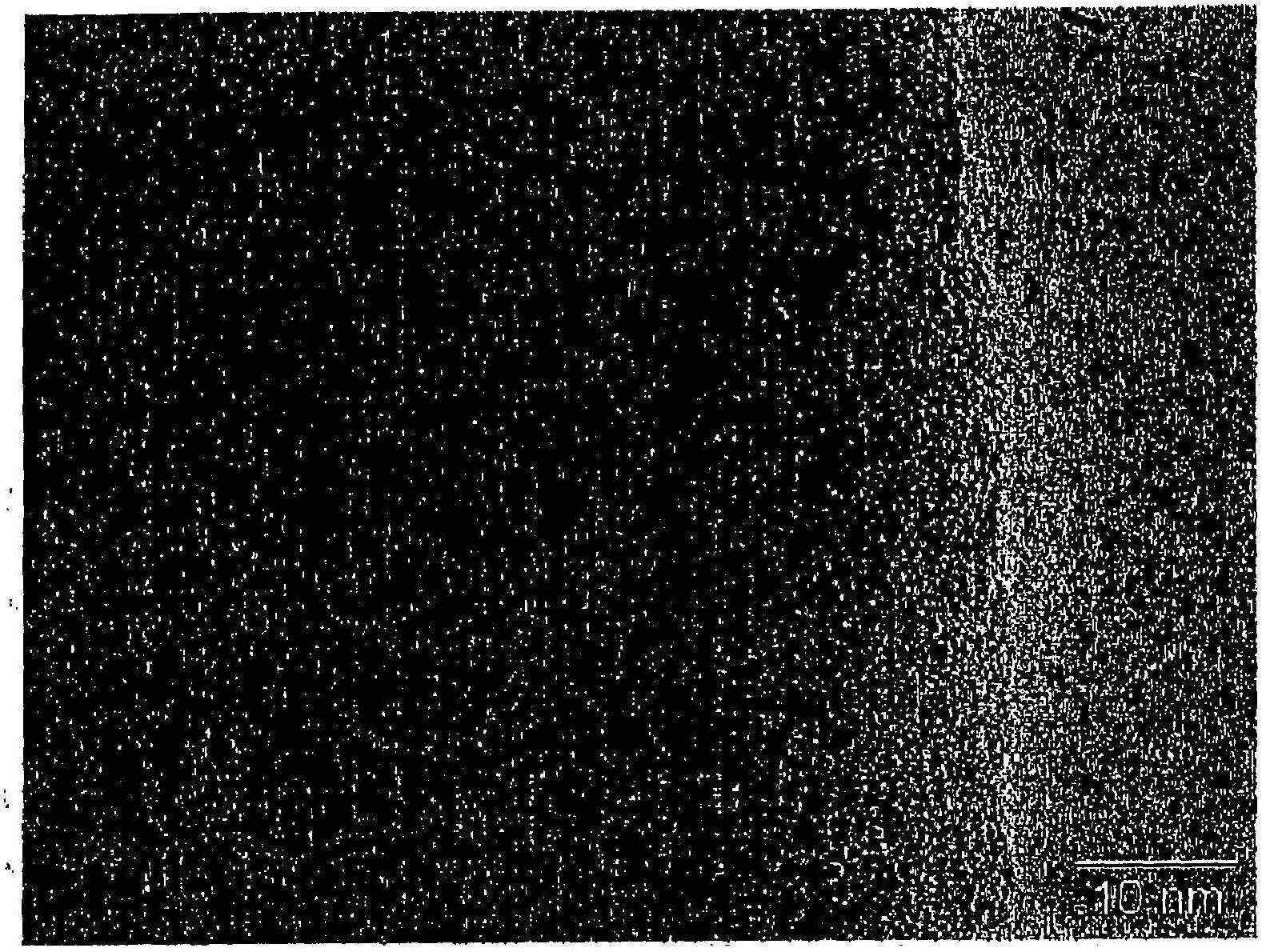

[0145] The obtained ultrafine carbon fiber nonwoven fabric was observed under an electron microscope, and it was confirmed that the fibers were not welded together. The fiber diameter is about 10 μm. The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com