Metal polyporous material with gradient pore structure and preparation thereof

A technology of metal porous and porous materials, which is applied in the field of metal porous materials and their preparation, can solve the problems of decreased permeability and pore diameter reduction, and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

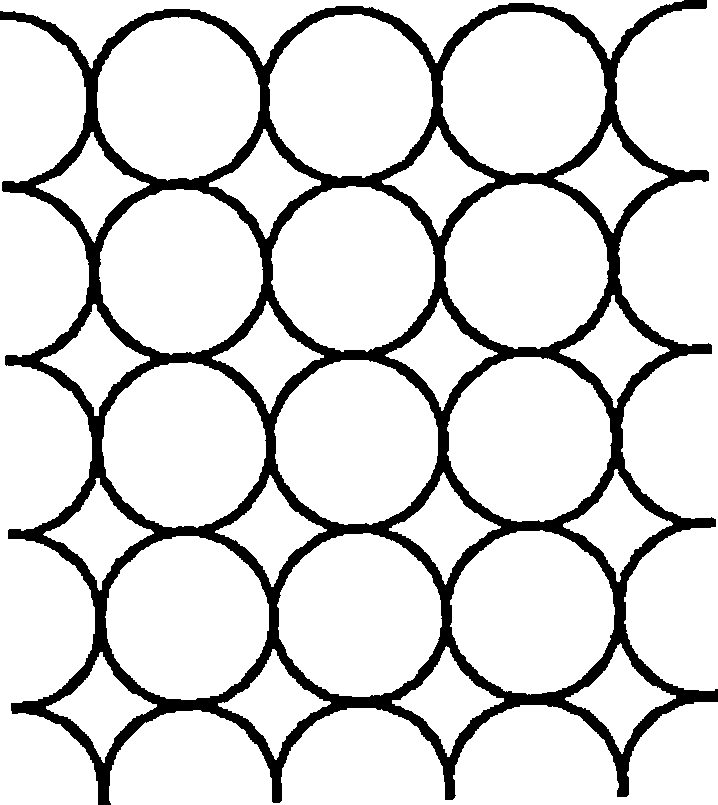

[0019] Gradient porous materials consist of two layers (see image 3 ), the pore diameter of the macroporous layer is 20 μm, and the pore diameter of the finely porous layer is 1 μm. The production process is to select 100-200 mesh stainless steel powder, and form it into a metal porous tube green body with a pore size of 20 μm and a diameter of Φ50×500 mm by cold isostatic pressing. The green body is sintered in a hydrogen atmosphere at 1350 ° C to obtain a sintered metal porous material as The support body is then sprayed, dipped, or centrifugally coated to form a fine-pore layer on the inner or outer wall of the support, with a pore size of 1 μm, and the fine-pore layer is composed of powder with an average particle size of 1 μm. its microstructure see Figure 6 , and its air permeability coefficient is shown in Table 1.

Embodiment 2

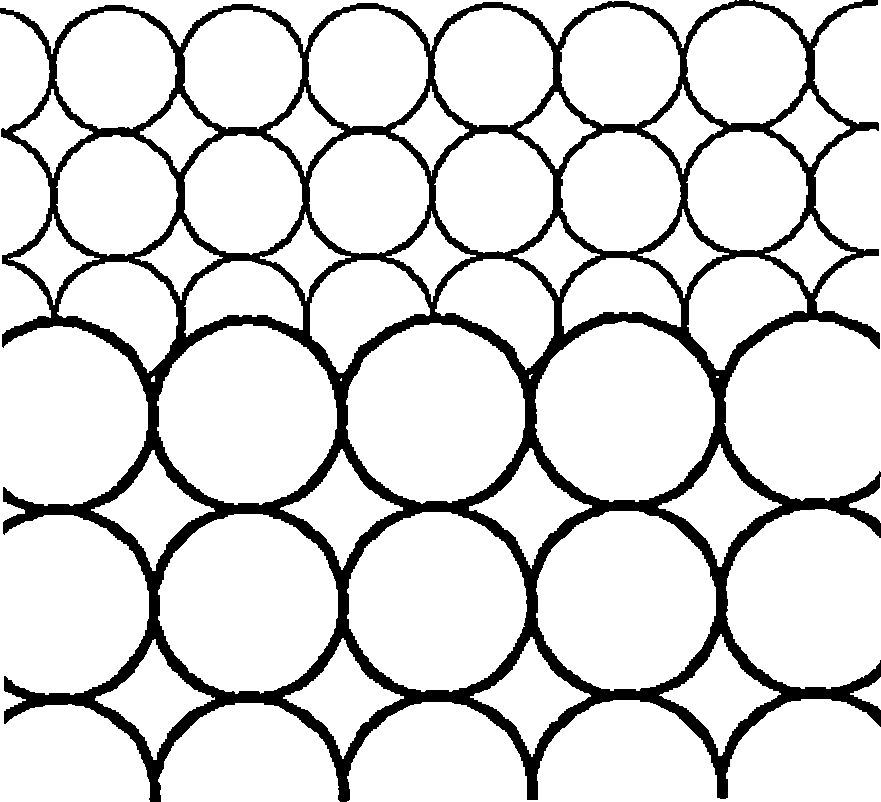

[0021] Gradient porous materials consist of multilayer structures (see Figure 5 ), the pore diameter of the macroporous layer is 20 μm, and the pore diameter of the finely porous layer is 1 μm. The production process is to select 100-200 mesh stainless steel powder, and form it into a metal porous tube green body with a pore size of 20 μm and a diameter of Φ50×500 mm by cold isostatic pressing. The green body is sintered in a hydrogen atmosphere at 1350 ° C to obtain a sintered metal porous material as Support body, and then use the method of spraying or dipping, or centrifugal coating to make multi-layer fine-pore layer successively on the inner wall or outer wall of the support. 10μm, 5μm, 1μm, 0.5μm powder composition. its microstructure see Figure 7 , the properties are shown in Table 1.

Embodiment 3

[0023] Gradient porous materials consist of two layers (see image 3 ), the pore diameter of the macroporous layer is 20 μm, and the pore diameter of the finely porous layer is 1 μm. The production process is to select a five-layer composite wire mesh metal porous material with a pore size of 20 μm (for its microstructure, see Figure 6 ), its shape can be pipe, plate or sheet, etc., and then use the method of spraying or dipping, or centrifugal coating to make a layer of fine-pored layer on the outer surface of the five-layer composite screen, the aperture is 1 μm, and the fine-pored layer is Composed of powder with an average particle size of 1 μm.

[0024] Table 1 Performance comparison between traditional metal porous materials and gradient metal porous materials

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com