Antibacterial meta-aramid fiber and preparation method thereof

A technology of aramid fiber and antibacterial agent, which is applied in the field of antibacterial meta-aramid fiber and its preparation, which can solve the problems of unsatisfactory antibacterial performance and unchanged antibacterial performance of meta-aramid fiber, so as to maintain permanent antibacterial ability and improve antibacterial efficiency , The effect of facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

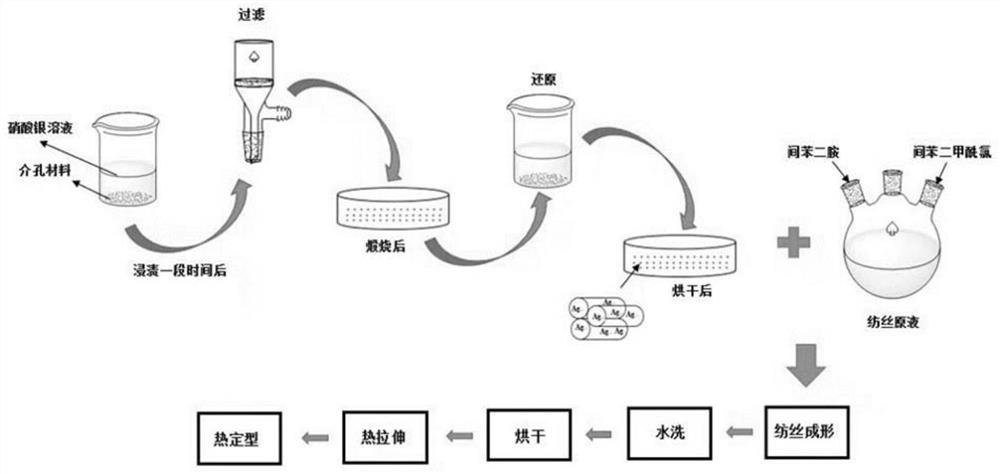

Method used

Image

Examples

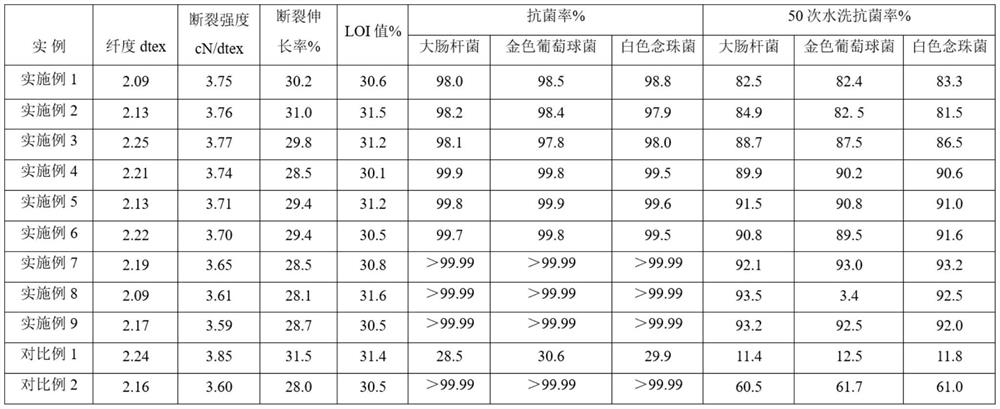

Embodiment 1

[0067] Choose the mesoporous material MCM-41 with a pore size of 10nm and a specific surface area of 500m 2 / g, disperse 50gMCM-41 in 500g mass concentration of 1% silver nitrate solution, immerse MCM-41 in the silver nitrate solution for 2h at 50°C, then wash with water for 3 times, filter to obtain filter cake, filter The cake was vacuum-dried at 60° C. for 6 hours to obtain a mesoporous material loaded with silver ions. The mesoporous material loaded with silver ions is calcined in a muffle furnace at 400°C for 2 hours, and becomes powder after cooling. The powder is dispersed in water, and 50 g of hydrazine hydrate with a mass concentration of 3.5% is added dropwise. After fully reacting, it is washed with water and filtered. Dry at 60° C. for 6 hours to obtain silver-loaded antimicrobial agent powder of mesoporous material.

[0068] Add 2.725mol m-phenylenediamine to 2.5kg N,N-dimethylacetamide, stir and dissolve, then cool the reaction system to -5°C, add isophthaloyl...

Embodiment 2

[0070] Choose the mesoporous material SBA-15 with a pore size of 10nm and a specific surface area of 1000m 2 / g, 50g SBA-15 is dispersed in 500g mass concentration and is in the silver nitrate solution of 1%, under the condition of 50 ℃, in the silver nitrate solution, SBA-15 is soaked 2h, carry out 3 times of water washing afterwards, obtain filter cake after filtering, filter The cake was vacuum-dried at 60° C. for 6 hours to obtain a mesoporous material loaded with silver ions. The mesoporous material loaded with silver ions is calcined in a muffle furnace at 400°C for 2 hours, and becomes powder after cooling. The powder is dispersed in water, and 50 g of hydrazine hydrate with a mass concentration of 3.5% is added dropwise. After fully reacting, it is washed with water and filtered. Dry at 60° C. for 6 hours to obtain silver-loaded antimicrobial agent powder of mesoporous material.

[0071] Add 2.725mol m-phenylenediamine to 2.5kg N,N-dimethylacetamide, stir and dissol...

Embodiment 3

[0073] Choose the mesoporous material CMK-3 with a pore size of 10nm and a specific surface area of 1000m 2 / g, disperse 50g CMK-3 in 500g mass concentration of 1% silver nitrate solution, immerse CMK-3 in silver nitrate solution for 2h at 50°C, wash with water 3 times afterwards, filter to obtain filter cake, filter The cake was vacuum-dried at 60° C. for 6 hours to obtain a mesoporous material loaded with silver ions. The mesoporous material loaded with silver ions is calcined in a muffle furnace at 400°C for 2 hours, and becomes powder after cooling. The powder is dispersed in water, and 50 g of hydrazine hydrate with a mass concentration of 3.5% is added dropwise. After fully reacting, it is washed with water and filtered. Dry at 60° C. for 6 hours to obtain silver-loaded antimicrobial agent powder of mesoporous material.

[0074] Add 2.725mol m-phenylenediamine to 2.5kg N,N-dimethylacetamide, stir and dissolve, then cool the reaction system to -5°C, add isophthaloyl ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com