Assembly type firewall

A firewall and prefabricated technology, used in fire prevention, walls, building components, etc., can solve the problems of high proportion of firewall body engineering, large amount of scaffolding and formwork engineering, and large impact on the surrounding environment, and is conducive to safe and civilized construction. The effect of managing, ensuring the integrity of nodes, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

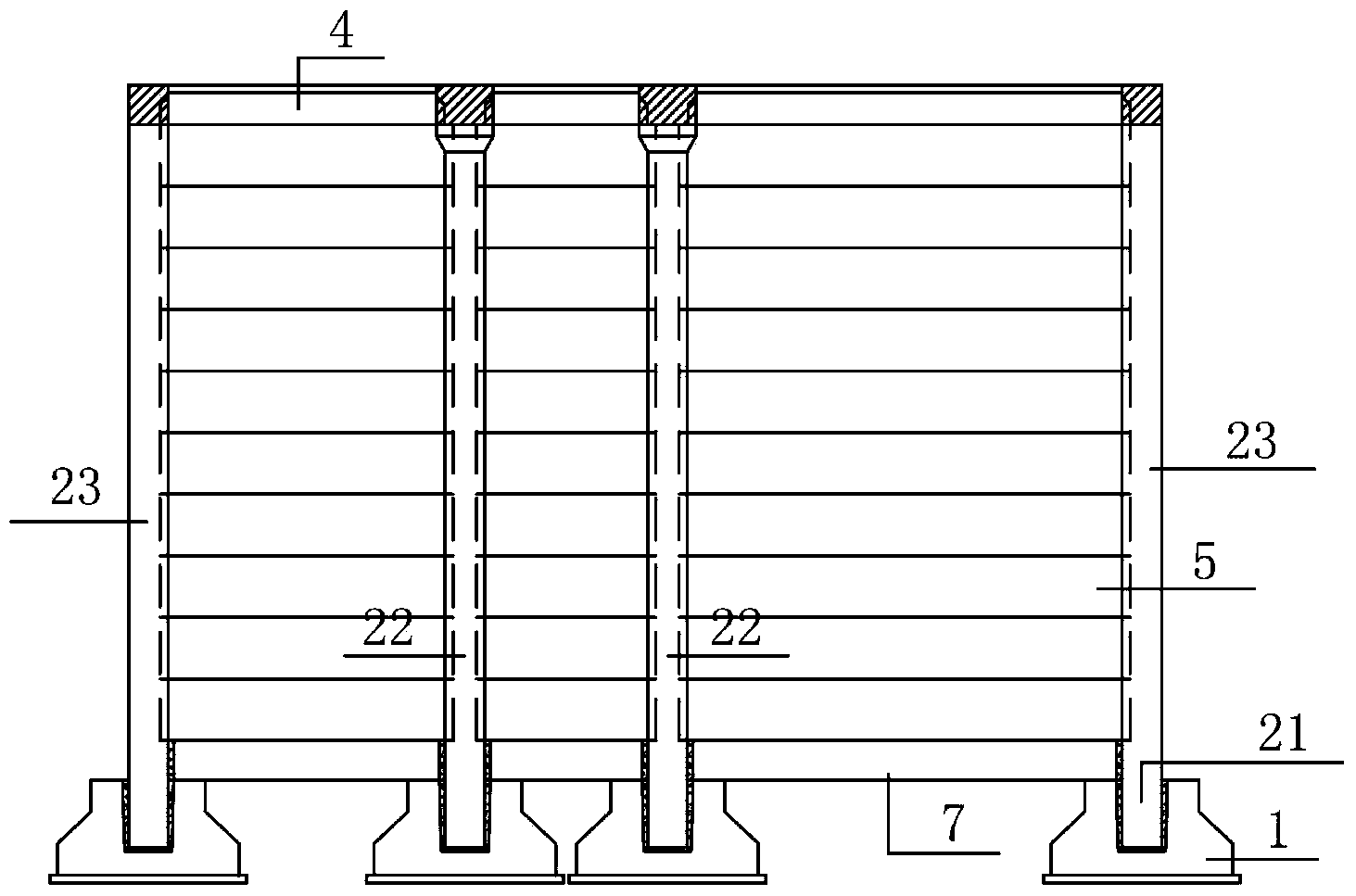

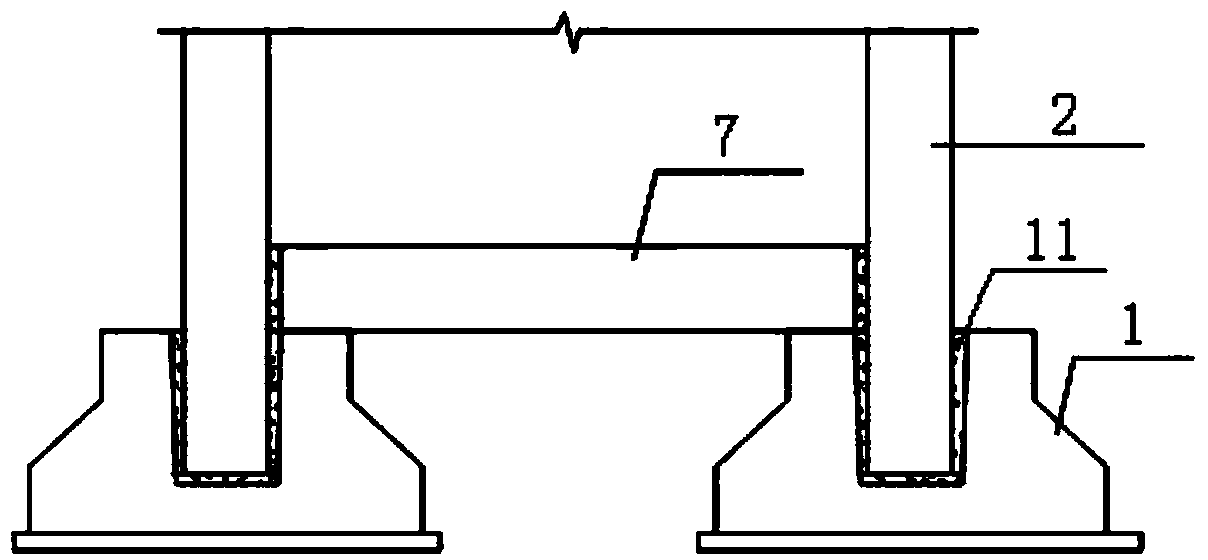

[0029] As shown in the figure, the prefabricated firewall is characterized in that it includes a plurality of foundations 1, a plurality of vertically arranged support columns 2, a plurality of horizontally arranged wall beams 3 and a first groove 40 at the bottom The top beam of the wall 4;

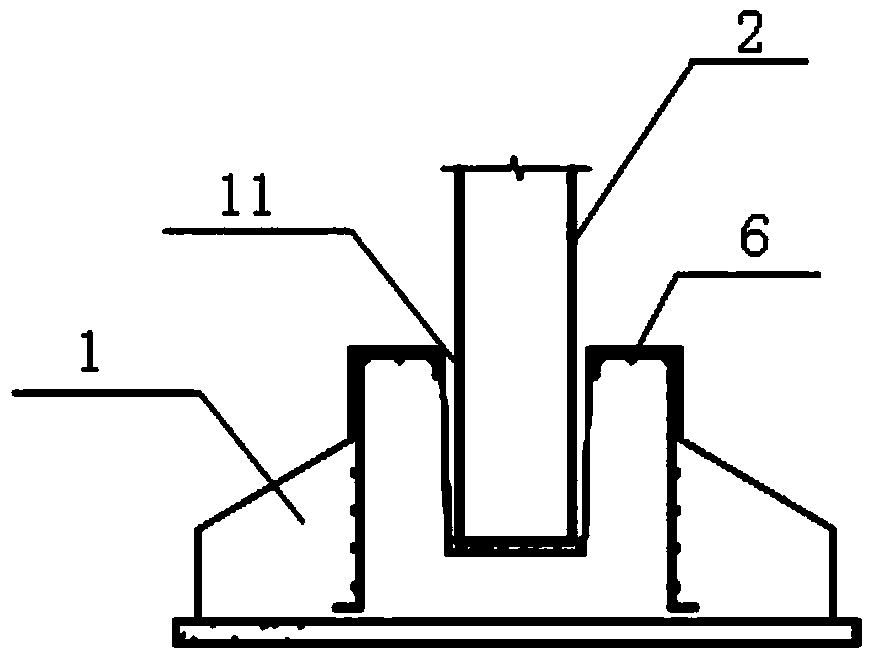

[0030] The foundation 1 is a cast-in-place cup structure, and the support column 2 is composed of a base column 21, a middle column 22 or a side column 23 from bottom to top. The base column 21 is placed in the cup mouth 11 of the foundation 1, and the horizontal The cross section is rectangular; the two opposite sides of the central column 22 are provided with an I-shaped groove 220 for installing the wall beam 3; one side of the side column 23 is provided with a second groove for installing the wall be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com