Jig frame tooling component for longitudinal bulkhead segmented general assembling construction

A technology of segmented general assembly and longitudinal bulkhead, which is applied in the directions of ship components, transportation and packaging, ships, etc., to achieve the effect of reducing costs, simple and convenient use, and improving the efficiency of cranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

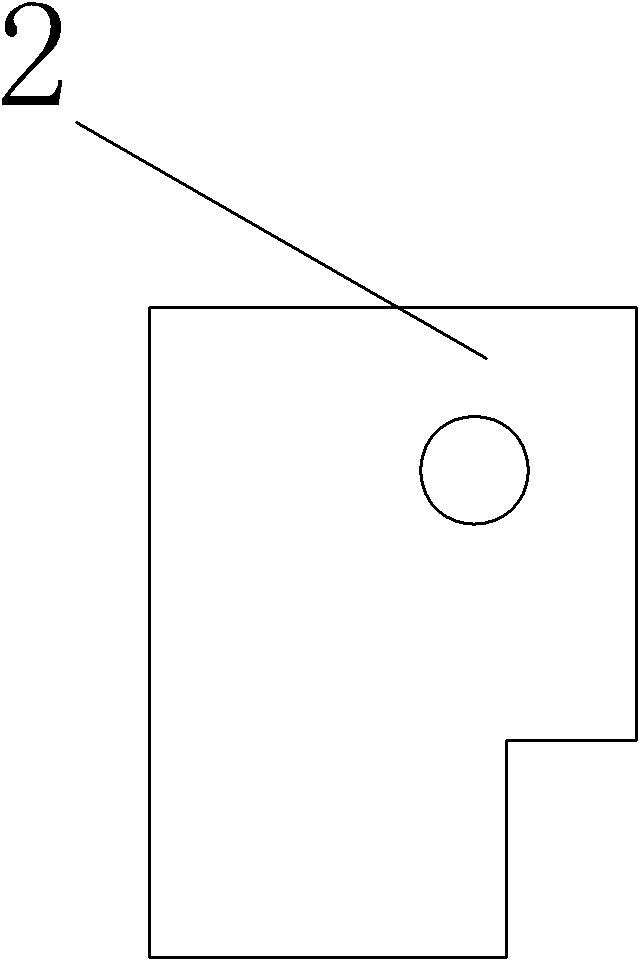

Image

Examples

Embodiment approach

[0022] The size of each part of the tooling member of the present invention is determined according to the specific shape of the segmented longitudinal bulkhead to be supported in the shipbuilding process. In order to enhance the versatility, the present invention provides a set of size parameters widely suitable for the use of various longitudinal bulkhead sections. Wherein, the height of big baffle 2 is 4 times of small baffle 3, and the distance between big baffle 2 bottom notch inner side and small baffle 3 outsides is twice of small baffle 3 heights. Specifically, in one embodiment, if the height of the large baffle is 600mm, the height of the upper and lower notches on the large baffle is 200mm, and the depth of the notch is 120mm; the height of the corresponding small baffle is 150mm, and the distance between the small baffle and the slot The inner side of the mouth depth is taken as 300mm, that is to say, the shortest distance between the small baffle and the large baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com