Method for drawing hull section margin line

A hull and margin technology, applied in ship construction, ship parts, ships, etc., can solve problems such as increasing crane load and assembly work intensity and difficulty, hindering the improvement of enterprise shipbuilding level, and increasing the rate of large closing and cutting, etc. Achieve the effect of saving hoisting time, saving resources and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] This embodiment provides a method for drawing the margin line of the hull section, which can draw the margin line before the hull section is closed, and then carry out hoisting and closing, thereby reducing the time required for hoisting, and reducing Surgical rate, the method includes the following steps:

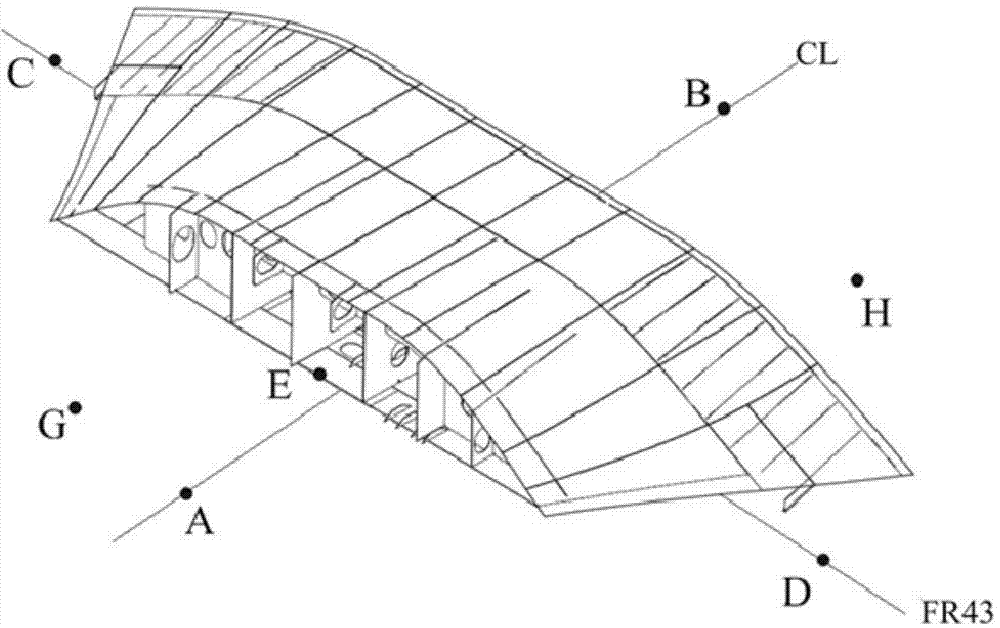

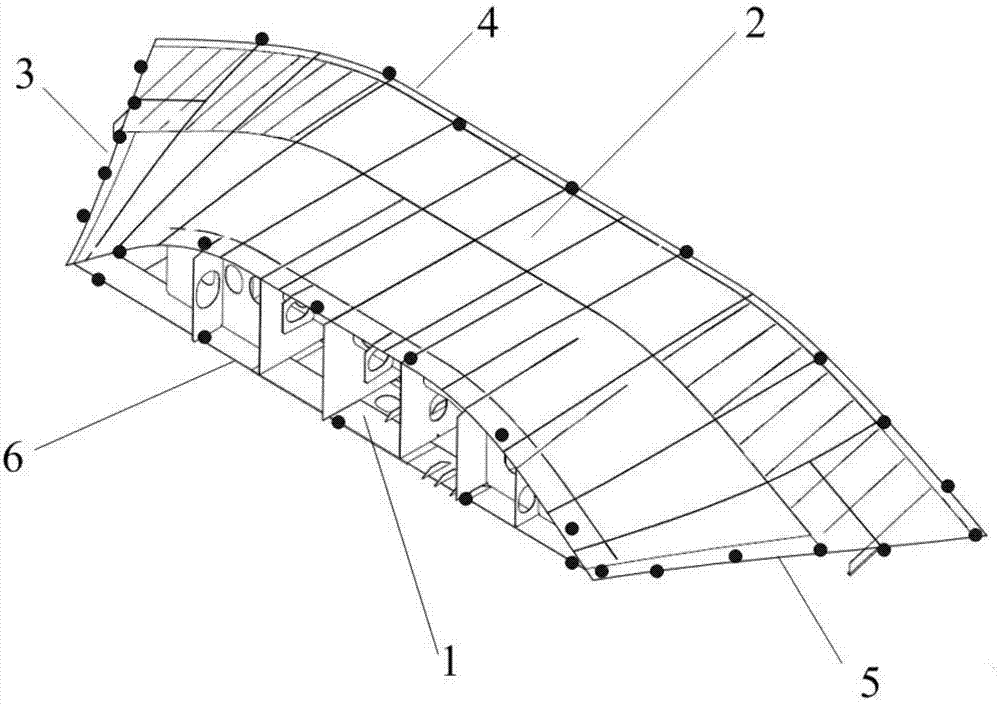

[0028] S110. Calculation: Calculate the required theoretical data value: first find the three-dimensional coordinate value of the intersection point of the upper opening of the outer plate 1 in the figure and the rib position line on the drawing of the segmented structure of the hull, that is, the distance from the segmental centerline The half-width value, the height value of the upper opening of the outer plate 1 to the inner bottom decking 2, the slope value of the upper opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com