Tower drum lifting appliance

A technology of towers and spreaders, applied in the directions of load hanging components, transportation and packaging, can solve problems such as insufficiency and the inability of lifting lugs to use a safety factor, so as to increase the scope of application and reduce the time and cost of research and development and manufacturing. , The effect of saving hoisting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments according to the present invention will now be described in detail with reference to the accompanying drawings, examples of which are shown, in which like reference numerals refer to like components throughout.

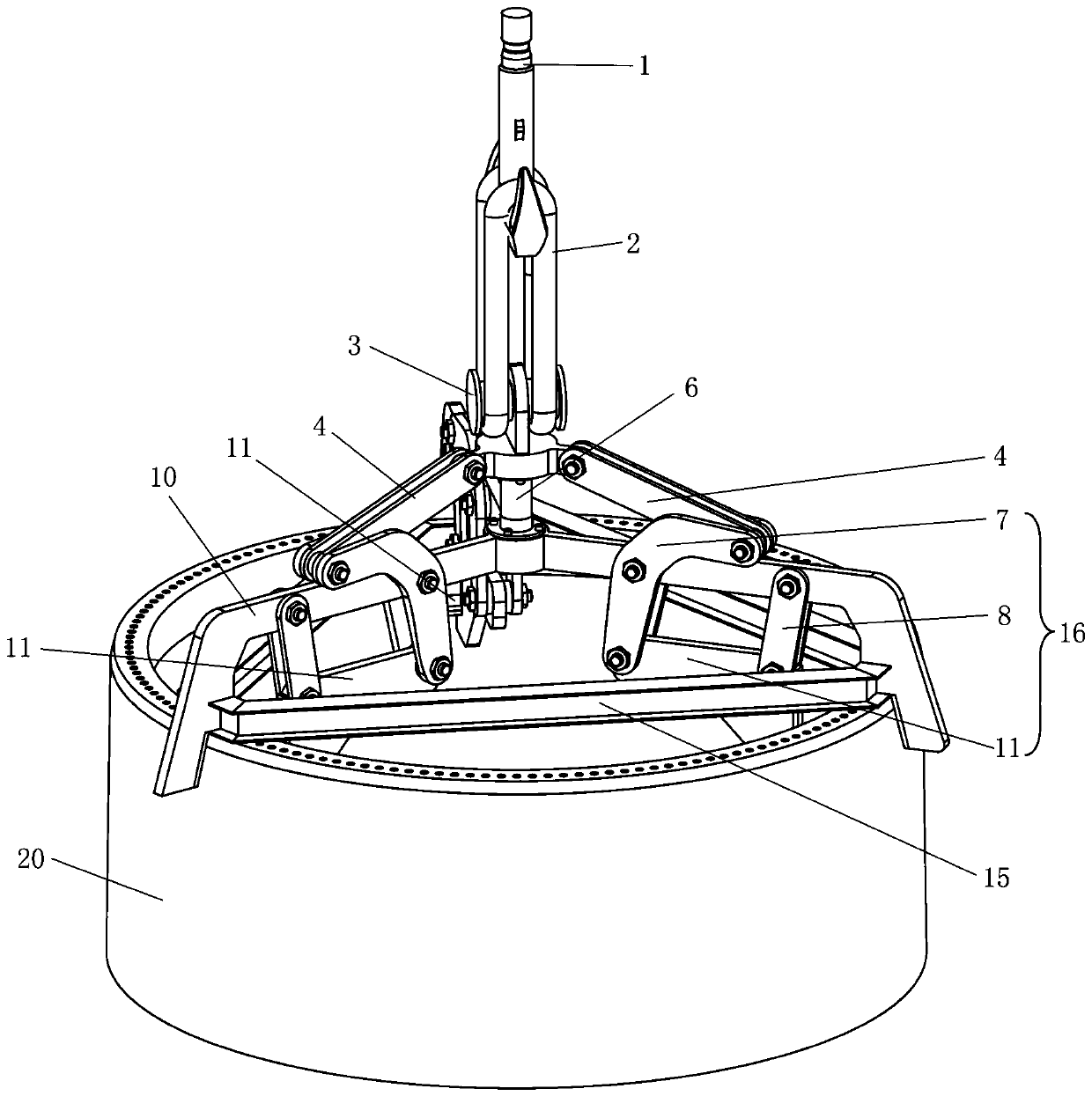

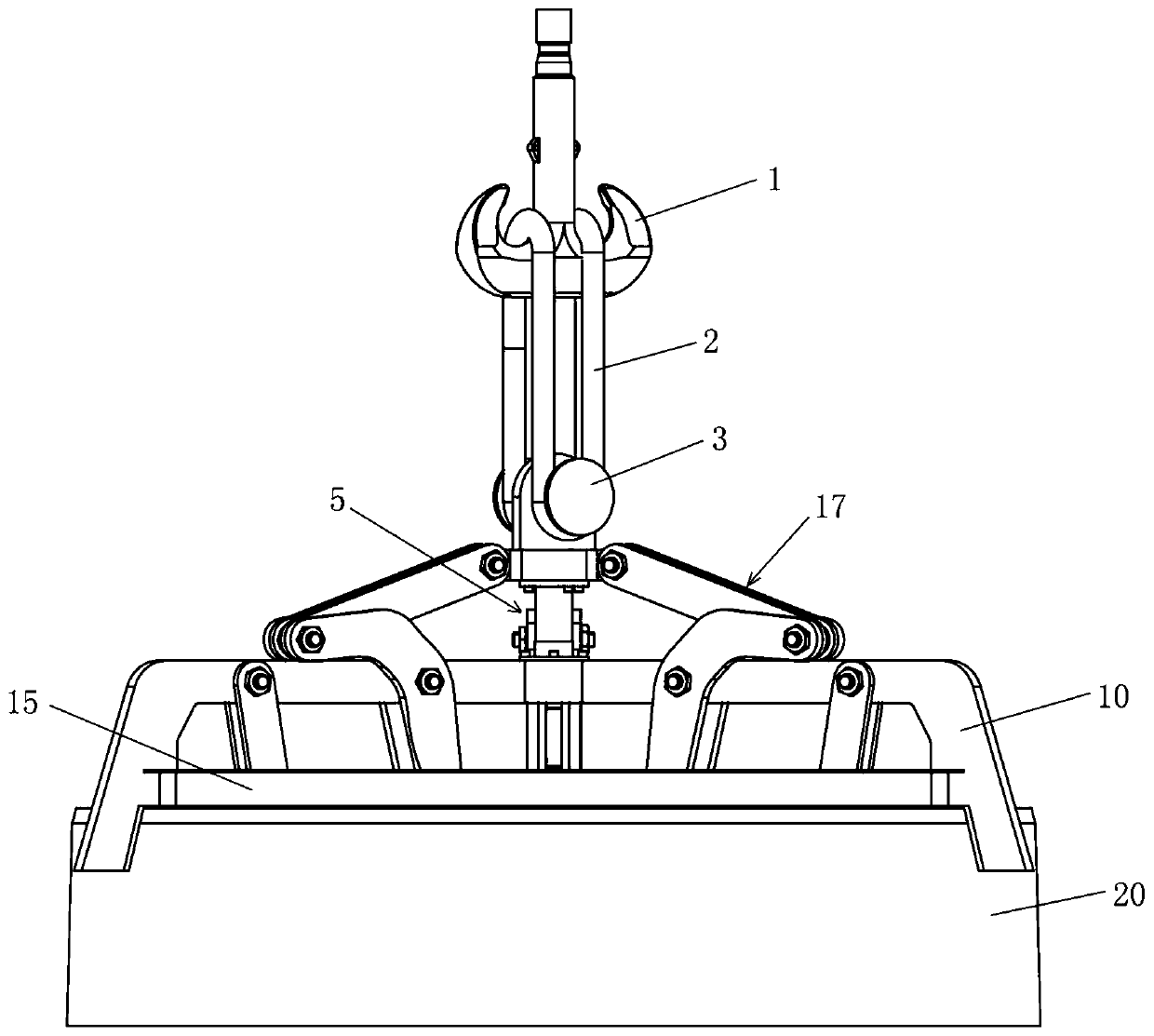

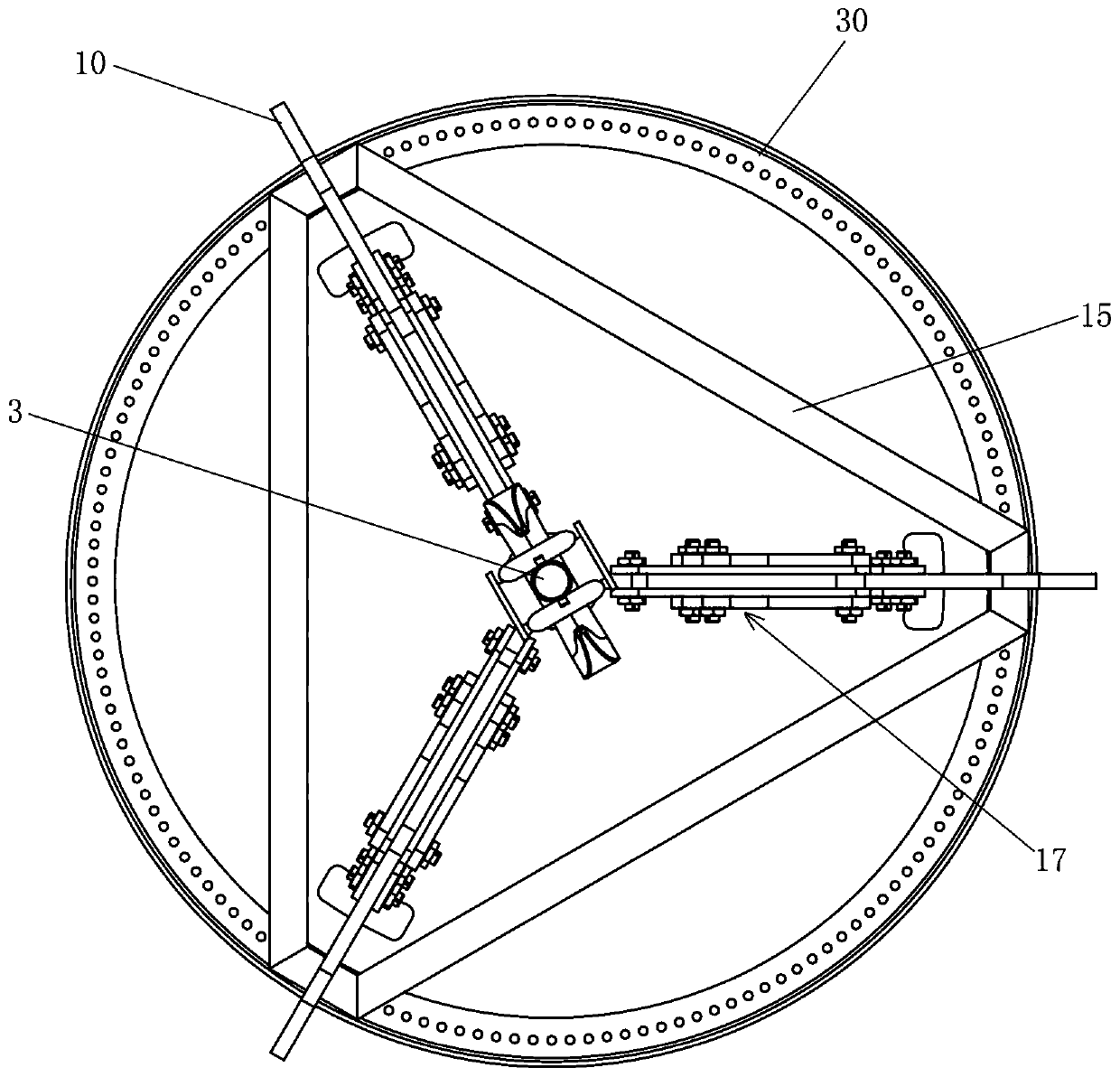

[0039] First, the structure of a tower spreader according to an exemplary embodiment of the present invention will be described with reference to the drawings. refer to Figure 1 to Figure 5 , the tower spreader according to the exemplary embodiment of the present invention includes a hanger 3 , a fixing frame 10 , at least two clamping arms 17 and a locking structure 5 . Wherein, the fixing frame 10 is located under the hanging base 3 , and the locking structure 5 can lock the hanging base 3 to the fixing bracket 10 or unlock it from the fixing bracket 10 . When using the tower spreader to perform hoisting operations, the hook 1 and the strap 2 can be connected to the hanger 3, in other words, the hanger 3 can provide a lifting point.

[0040] Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com