LNG storage tank in-tank pipeline mounting method

An installation method and inner pipeline technology are applied in hoisting devices, transportation and packaging, load hanging components, etc., which can solve the problems of high construction cost, high-altitude operation risk, and long construction time, so as to improve safety and avoid safety Risk issues, the effect of reducing altitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

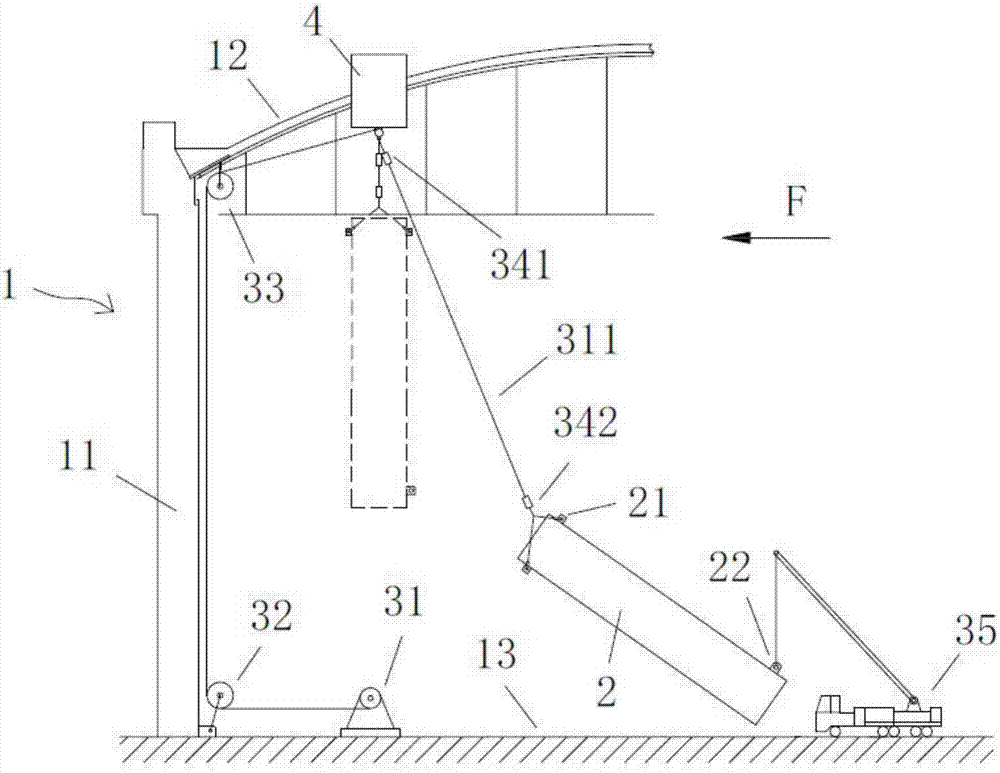

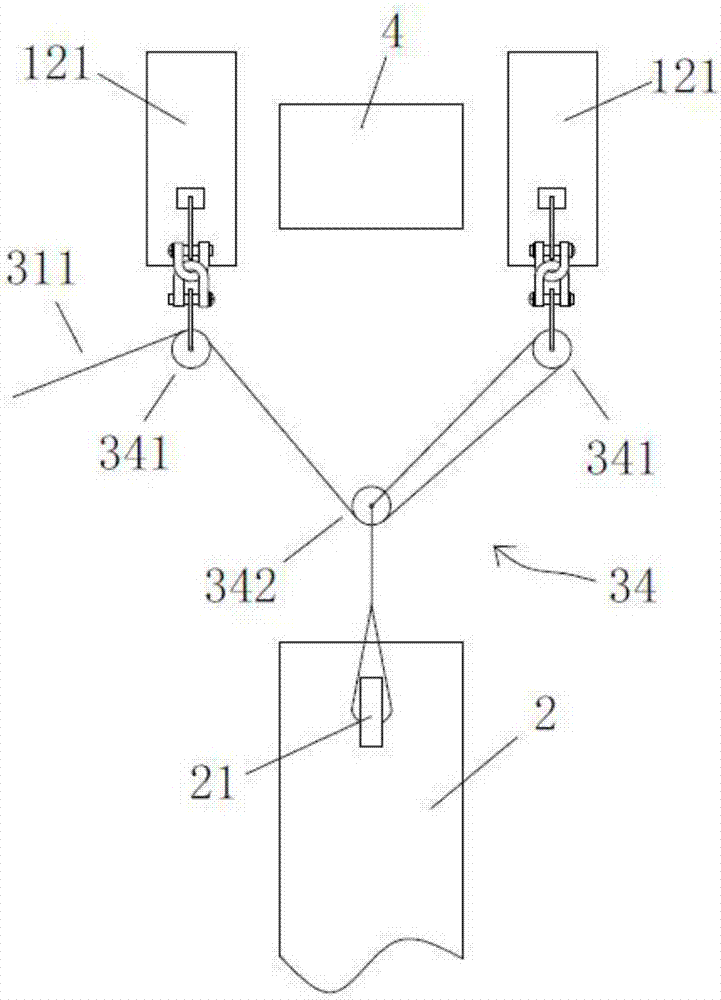

[0022] The technical solutions in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] combine figure 1 with figure 2 As shown, adopt the pipeline installation method in the LNG storage tank tank of the present invention, the concrete steps that the pipeline in the tank is installed are:

[0024] Step S1, prefabricating the pipeline in the tank. After the installation of the inner tank wall plate 11 and the storage tank dome 12 of the storage tank 1 is completed, all the segmented pipelines of the tank internal pipeline 2 are transported to the inside of the storage tank 1 . Carry out prefabrication work to tank inner pipeline 2 on the tank inner bottom plate 13, and place the tank inner pipeline 2 that has completed the prefabricated work horizontally on the tank inner bottom plate 13. In this way, by prefabricating super-long pipelines on the ground, the difficulty of operation can be reduced, the efficiency and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com