Control handle for hand hydraulic carrier

A technology of operating handle and truck, applied in the direction of lifting device, etc., can solve the problems of shortening the lifting time and slow lifting of manual hydraulic truck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

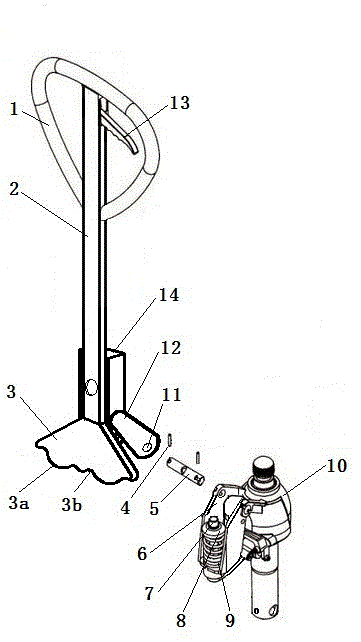

[0021] In order to better understand the improvement made by the present invention compared with the prior art, before describing the specific implementation of the present invention in detail, the prior art mentioned in the background art section will be described with reference to the accompanying drawings.

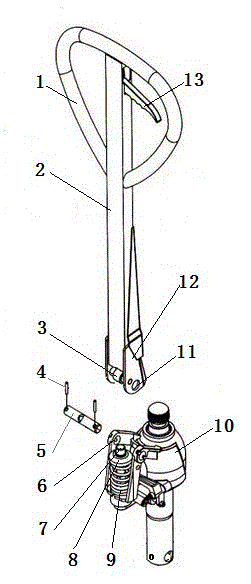

[0022] figure 1 The joystick of the existing manual hydraulic truck shown includes a rod body 2 and a ring handle 1. The ring handle 1 is installed on the rod body 2, which is convenient for the operator to press the rod body 2 and move the truck as a whole. Bar body 2 is also equipped with pinch handle 13 near the upper end part, and this pinch handle 13 has three gears, is respectively rising, neutral gear and descending, and when truck carries out lifting, pinch handle 13 should be adjusted to the rising gear. The rod body 2 is welded together with the guard plate 12, the pin shaft 5 passes through the pin shaft hole 11 on the guard plate 12 to connect the guard plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com