Precise aerial alignment system and method of suspension bridge steel bridge

A technology for suspension bridges and steel girders, which is applied in the direction of suspension bridges, bridges, bridge forms, etc., and can solve problems such as the difficulty of precise docking of steel girders in the air, low longitudinal pulling effect, and long working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

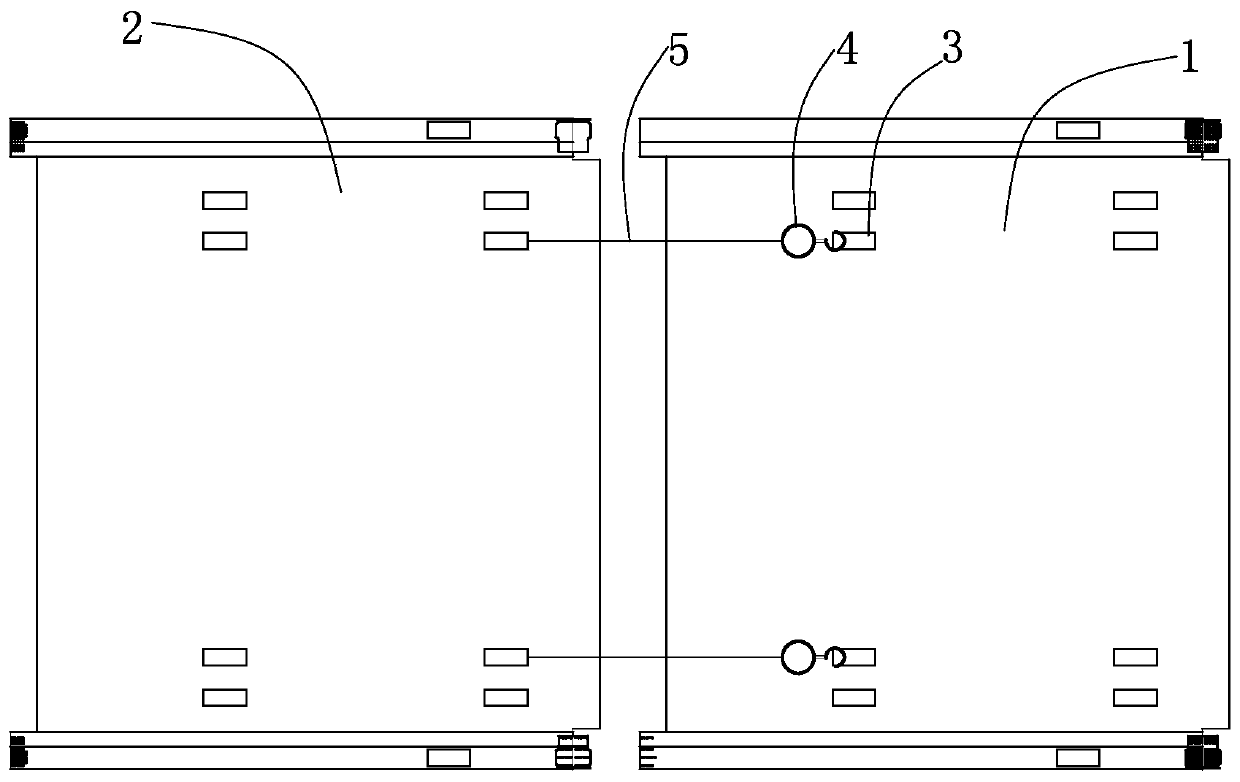

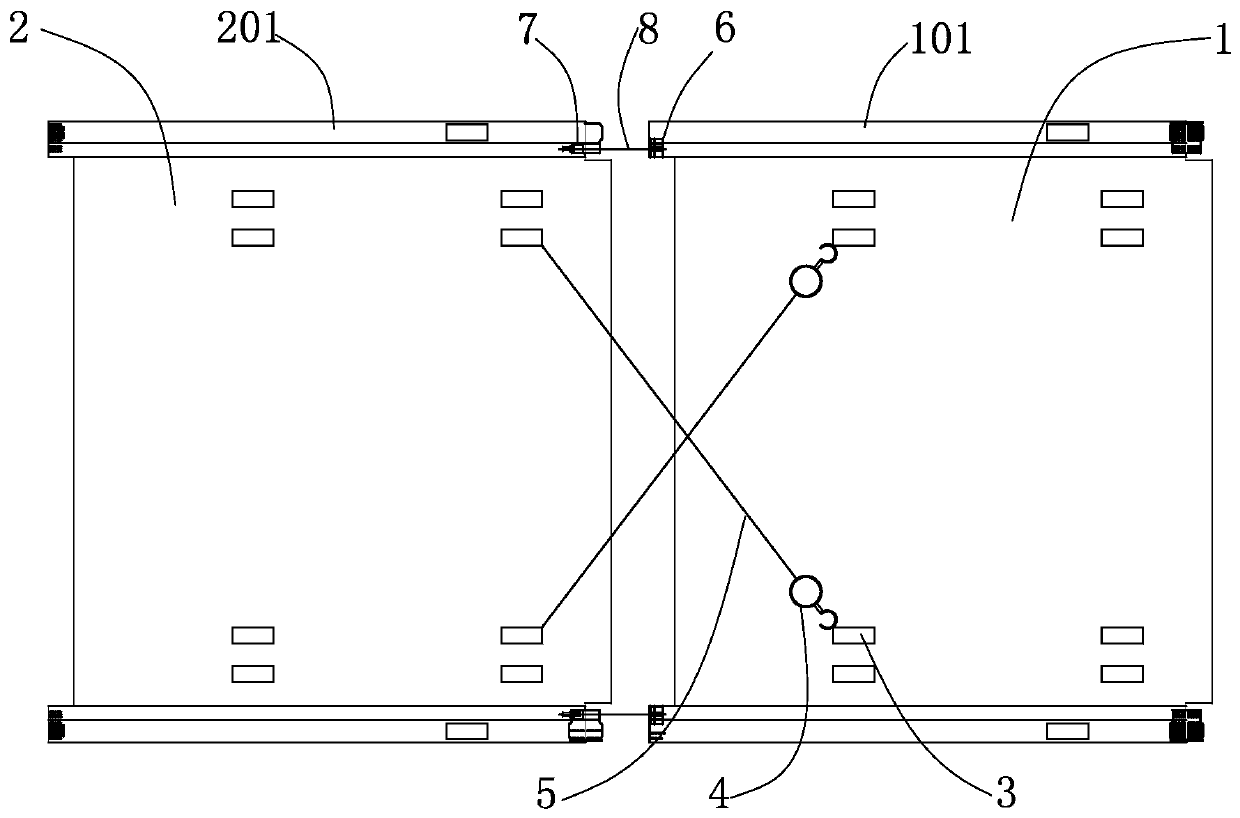

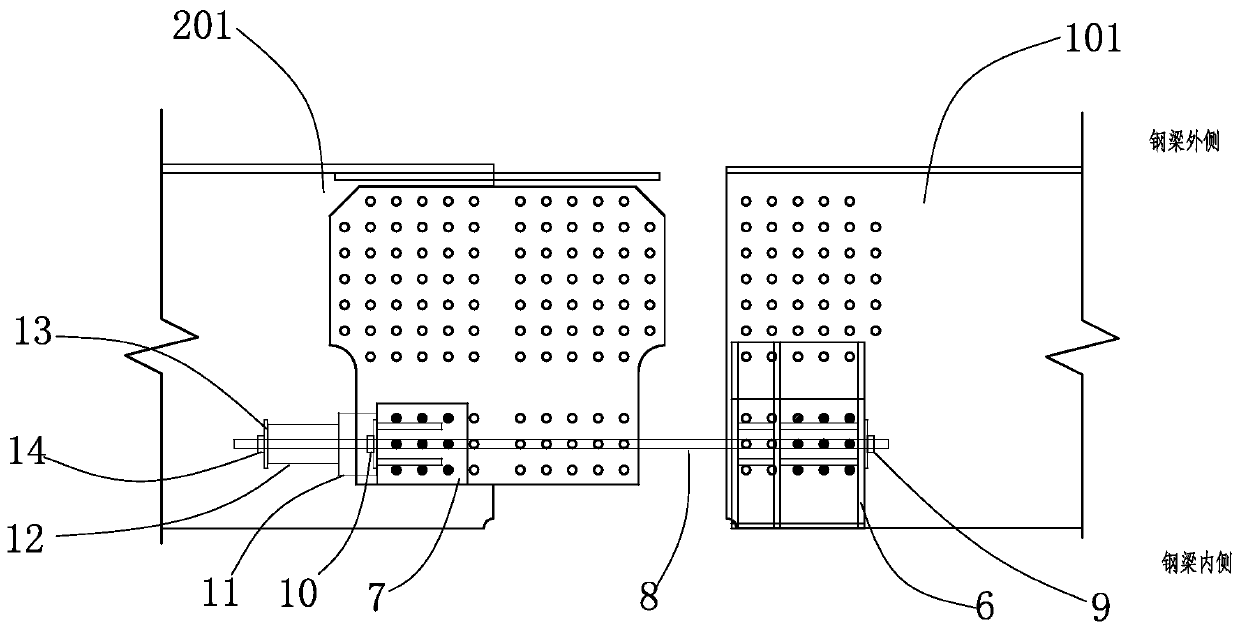

[0026] Such as figure 2 as shown, image 3 , Figure 4 As shown, a suspension bridge steel girder precision docking system in the air provided by the present invention, a fixing frame 6 is respectively arranged on the top surface of the two upper chords 101 of the first steel girder 1, and a fixing frame 6 is respectively arranged on the top surface of the butt joint ends of the two upper chords 101 of the first steel girder 1. Two steel beams 2, two upper chords 201 butt end top surfaces are respectively provided with a reaction force frame 7, and the fixed frame 6 and the reaction force frame 7 located on the same side of the two steel beams are connected by a pull rod 8, and one end of the pull rod 8 passes through the After the fixed frame 6 is screwed to the first fastening nut 9, the other end of the pull rod 8 is screwed to an auxiliary nut 10 after passing through the reaction force frame 7, and then passes through a box-shaped push bracket 11, a through-heart A typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com