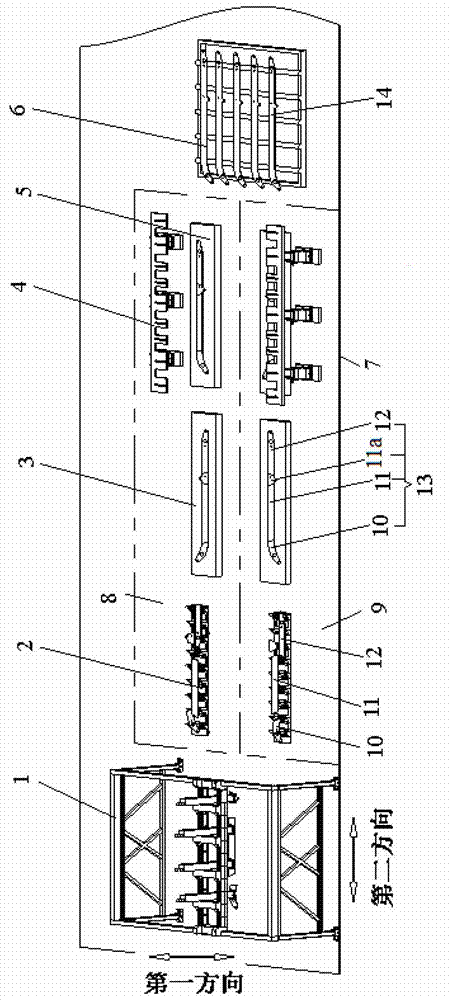

Sucker hoisting device and plate welding conveying system

A hoisting device and conveying system technology, applied in the direction of auxiliary devices, conveyor objects, welding equipment, etc., can solve the problems of potential safety hazards, low work efficiency, difficulty in adapting to plate parts, etc., and achieve convenient and reliable tailor welding processing, high Automated functions and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

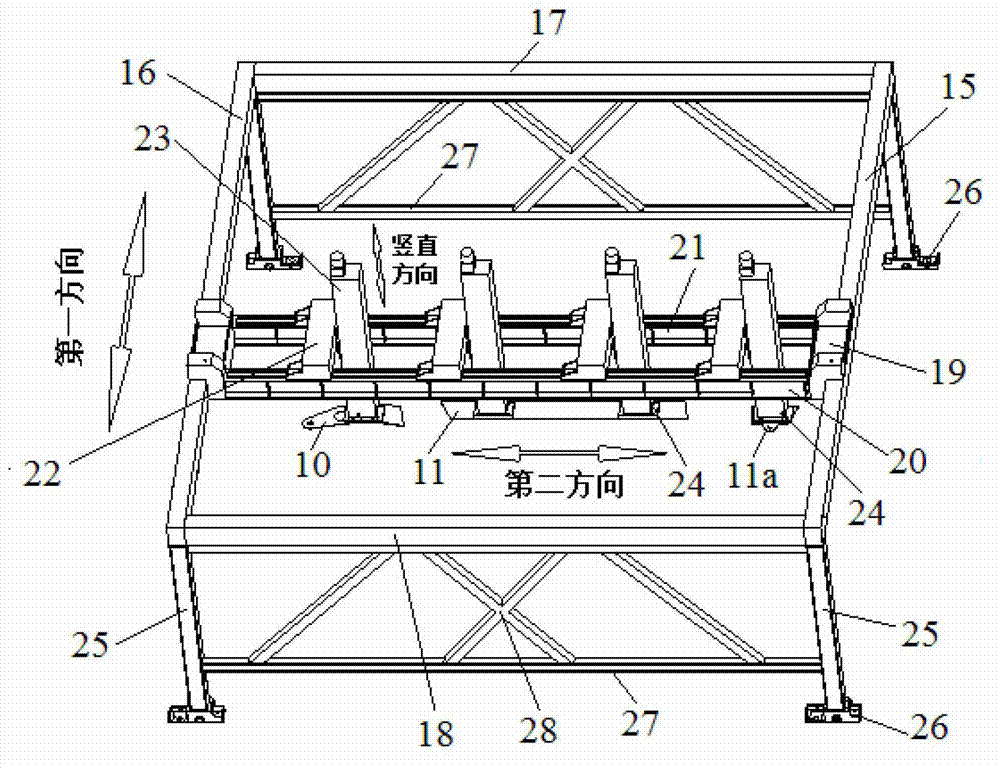

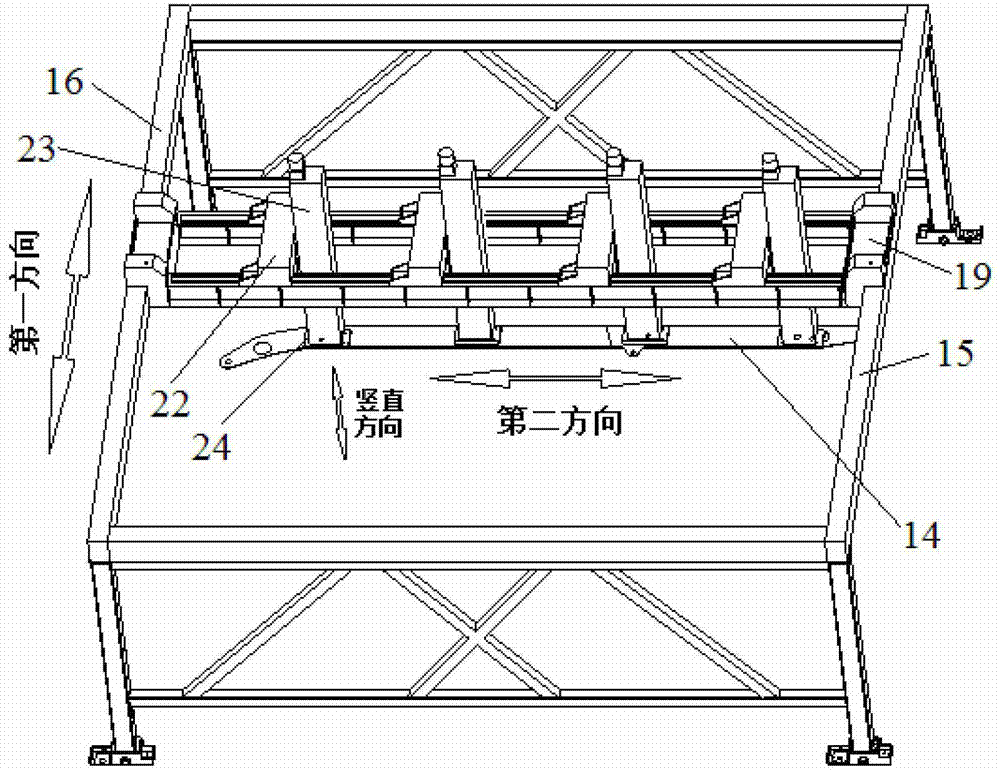

[0050] The specific embodiments of the present invention will be described in detail below with reference to the drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the scope of protection of the present invention is not limited to the following specific embodiments .

[0051] It is stated in advance that figure 2 with image 3 The suction cup hoisting device shown is only a preferred embodiment of the present invention. Within the technical concept of the present invention, the suction cup hoisting device of the present invention is not limited to the gantry type suction cup hoisting device shown in the figure, that is, it is not limited to the ground rail 7 moves on the ground in cooperation, it can also form a suspended suction cup hoisting device by using a wall rail or a hanging rail. In addition, although the mobile driving structure of the relevant component parts of the suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com