Construction method for cylindrical frame supporting type hydraulic-climbing integral steel platform formwork shear steel plate layer

A shear steel plate and construction method technology, applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, building components, etc., can solve problems such as low construction efficiency and poor safety, and achieve reduction The effect of hoisting times, acceleration of hoisting and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

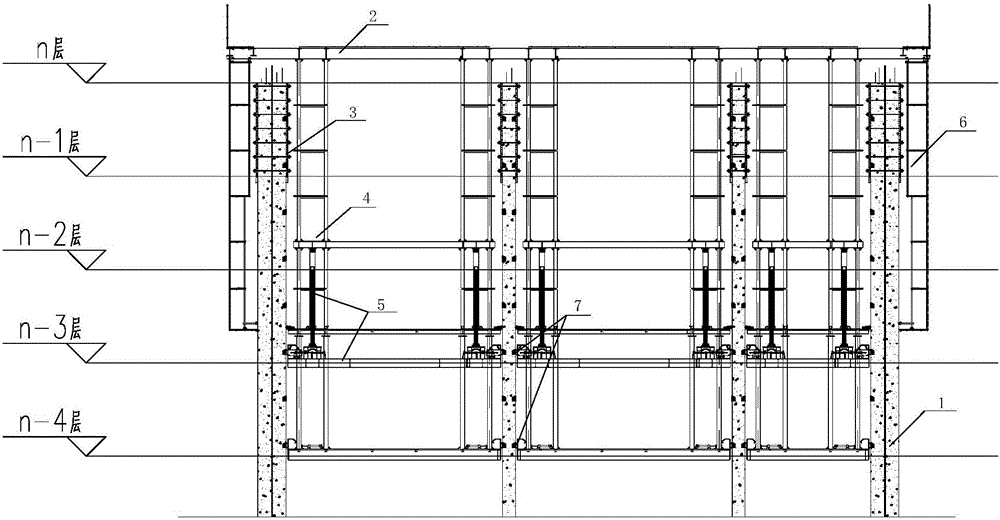

[0040] see Figure 1 to Figure 9 , the construction method includes the following steps:

[0041] Step 1: The formwork equipment of the cylinder support type hydraulic climbing integral steel platform is located on the top of the core tube wall 1 that has just been poured, and the formwork is fixed on the core tube wall 1 by fixing parts (not shown). Steel platform formwork equipment includes steel platform system 2, formwork system 3, cylinder support system 4, steel beam climbing system 5 and scaffolding system 6;

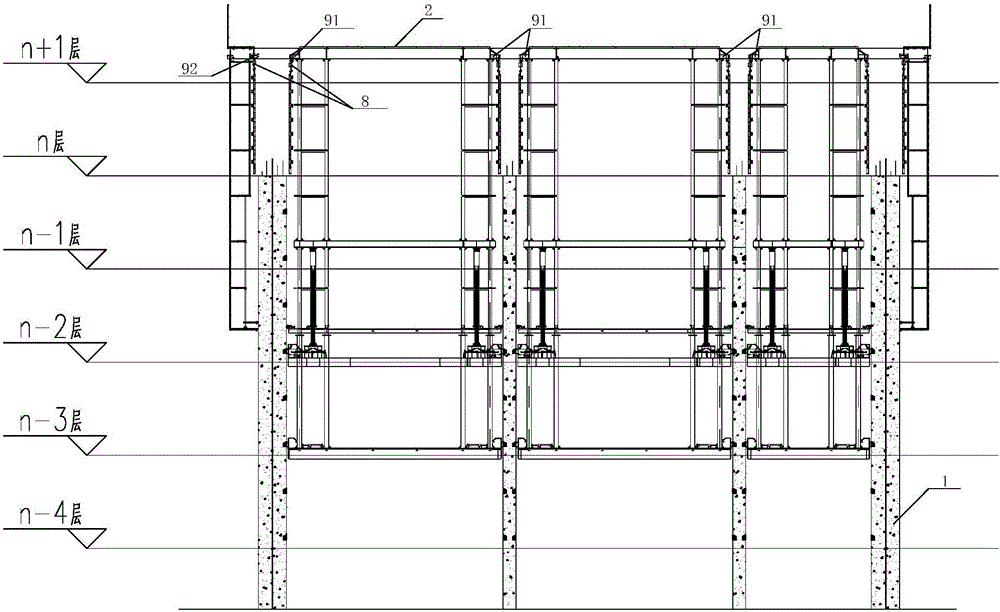

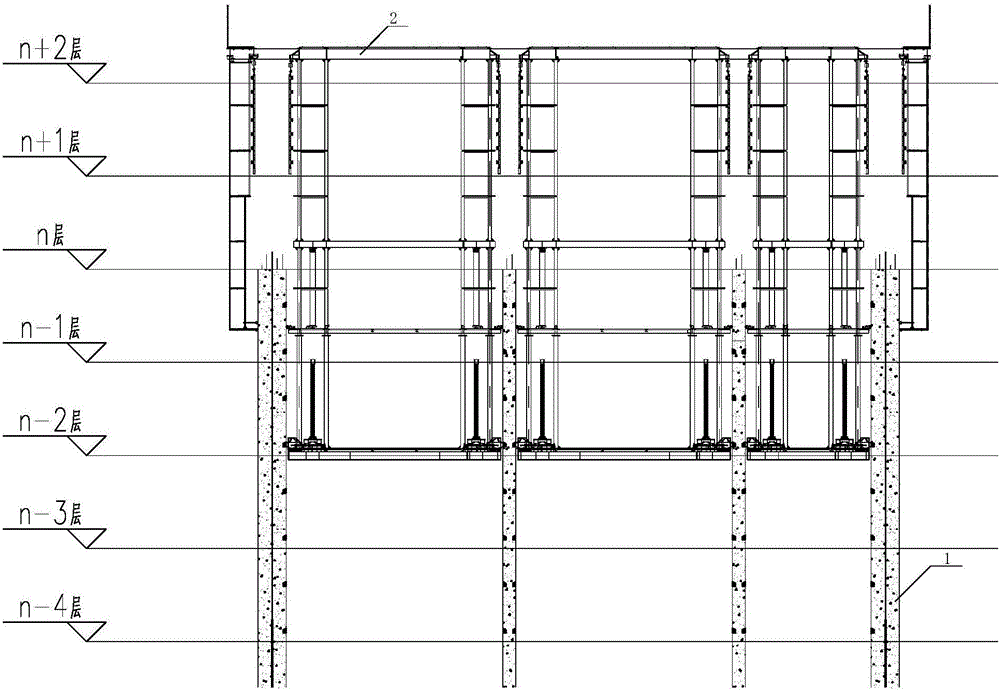

[0042] Step 2: Remove the fixing parts, use chain hoists 8 to fix the formwork on the lower end of the steel platform beam through the formwork lifting points set on the steel platform beam, and fix the formwork horizontal purlin on the hanger pole with lead wires; Step 3: Overall The steel platform formwork continuously climbs two storeys;

[0043] Step 4: Hoist the stiff column (not shown) and the shear steel plate 10, and install the shear steel plate 10 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com