Modularize building method for nuclear reactor of nuclear plant

A construction method and modular technology, which can be applied to the detailed information of nuclear power plants, nuclear power plants, nuclear power generation, etc., can solve problems such as shortening the construction period, the efficiency of large/super-large transport hoisting/hoisting machinery cannot be fully utilized, and the effect is not significant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

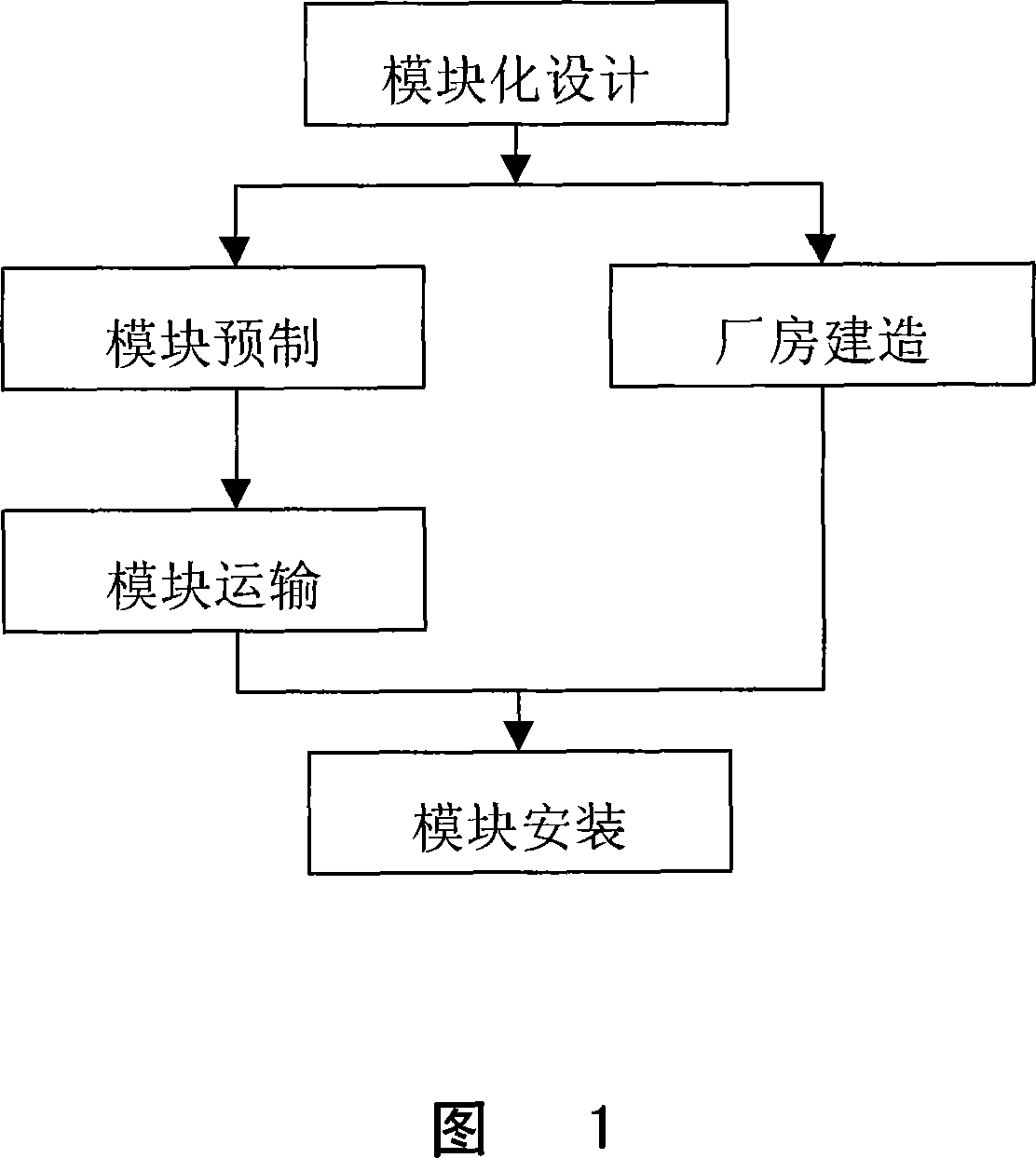

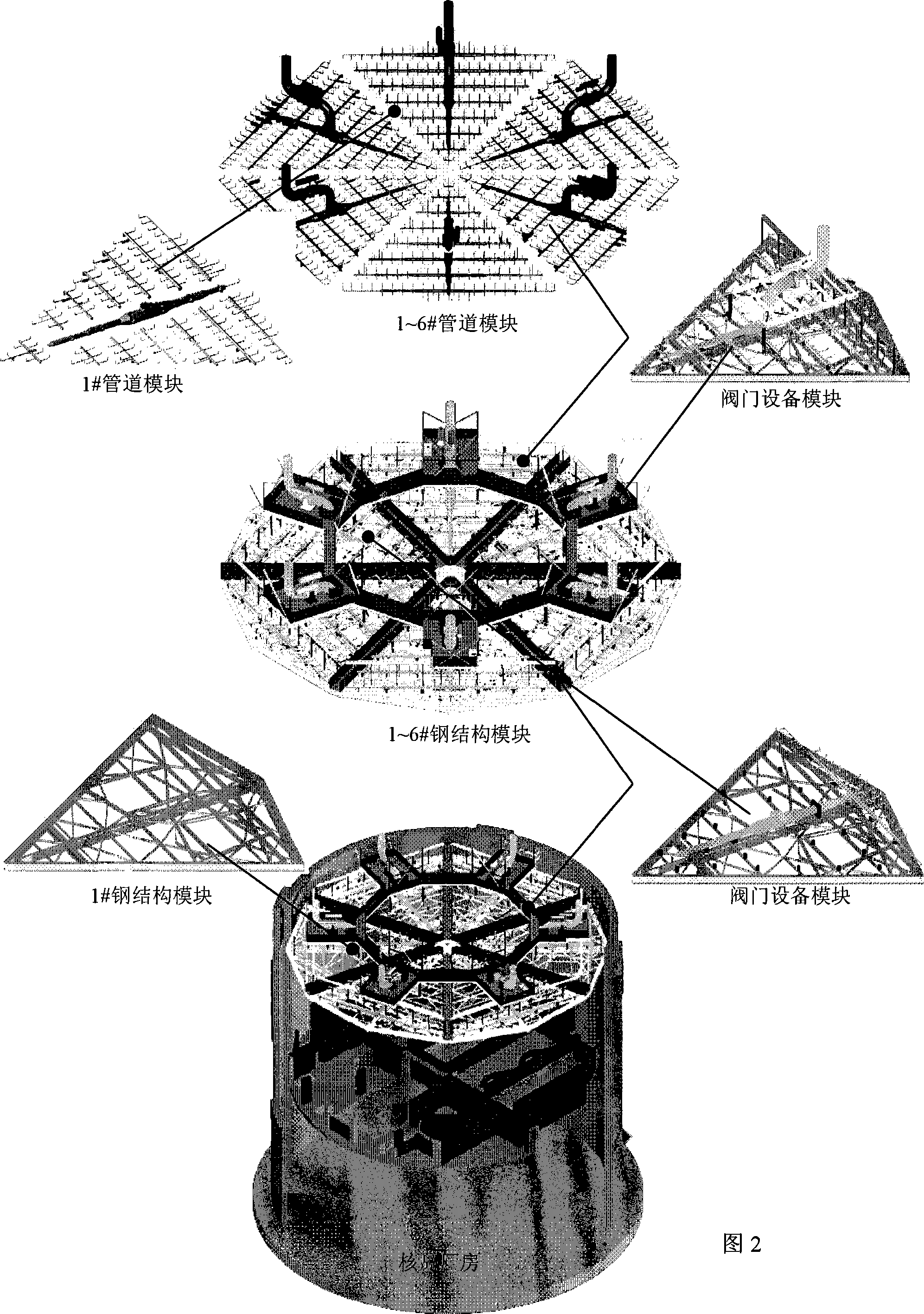

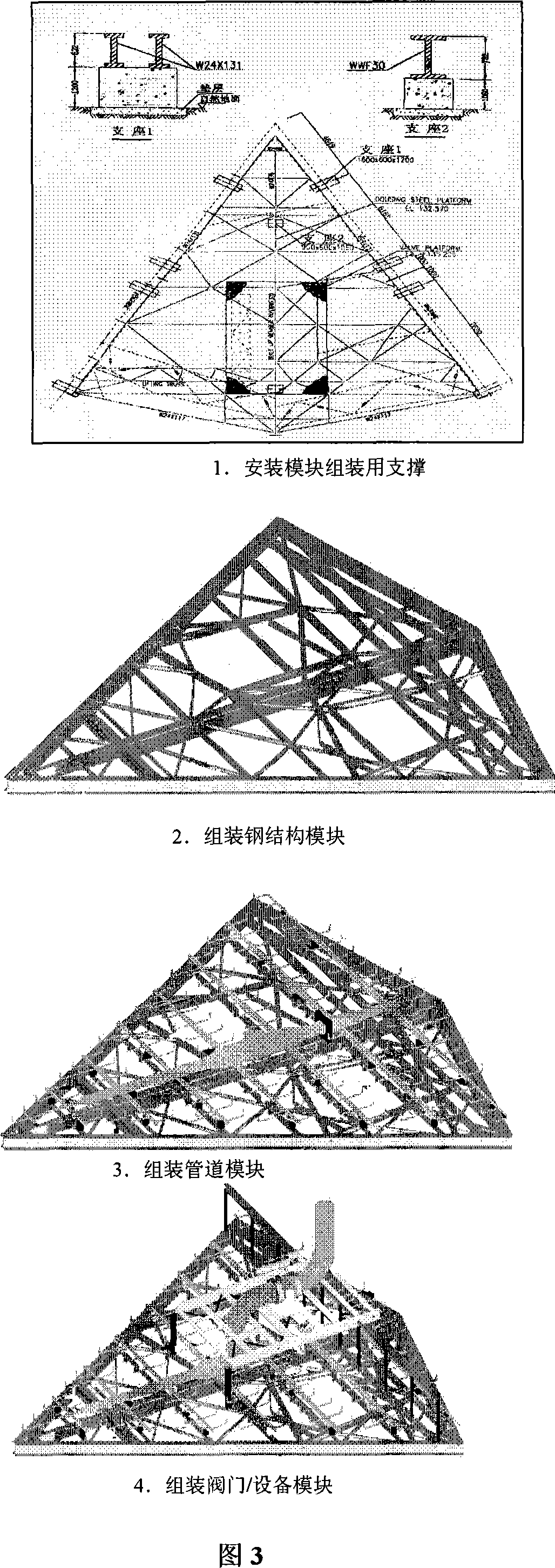

[0039]The present invention comprehensively analyzes various construction technologies, construction management methods and experience in the construction of nuclear island projects in the first and second rounds of nuclear power plants in my country. On the basis of the shortcomings of huge resources and huge investment in temporary infrastructure construction on site, the concept of modular construction is used to put forward the modular concept and modular design appeal for the upstream engineering design, and the traditional construction concept and construction technology are carried out in the construction stage of the project. optimized and refined. And introduce P3 plan management technology, computer three-dimensional model technology, nuclear power plant open top method construction technology, factory manufacturing concept, use the parallel construction organization method of construction and installation engineering, and carry out in-depth construction and installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com