Steel bar connecting piece, connecting method, connecting connector and special extrusion die

A technology for extruding dies and connecting joints, which is applied in the direction of connecting components, rods, building components, etc. It can solve the problems of large overlapping areas, large overlapping lengths, and difficulty in construction on site, so as to achieve good connection strength and prevent The effect of sleeve breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

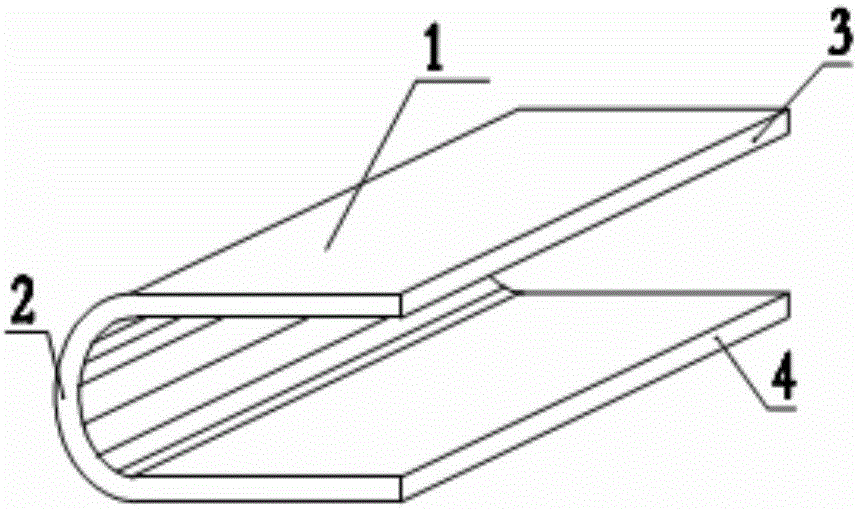

[0059] see image 3 , this embodiment is the second embodiment of the connector 1 for steel bar connection of the present invention, the difference between the connector 1 of this embodiment and the embodiment 1 is: the first steel plate segment 3 and The second steel plate section 4 is connected with an additional arc-shaped steel plate section 2-1 at the end opposite to the arc-shaped steel plate section 2, and the arc surface of the additional arc-shaped steel plate section 2-1 is connected to the first steel plate Segment 3 is tangent to second steel plate segment 4 . The cross-section of the connecting piece 1 in this embodiment is in the shape of an oblong shape similar to a standard runway in a playground.

specific Embodiment approach

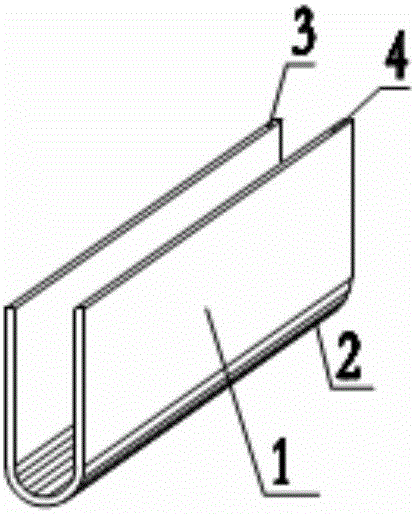

[0061] see Figure 4 with Figure 5 , this embodiment is a specific implementation of the connection method for steel bar connection realized by the connector 1 described in the application embodiment 1 of the present invention, and the connection method includes the following steps:

[0062] (1) The connecting ends of the reinforcing bar A5 and the reinforcing bar B6 to be connected are brought together in parallel to form an overlapping overlapping section, and the length of the overlapping overlapping section is greater than the length of the connector 1;

[0063] (2) Buckle the connecting piece 1 on the overlapping section of steel bar A5 and steel bar B6, and let one of the steel bars A5 reach the arc-shaped bottom of the connecting piece 1 and make it close (see Figure 4 );

[0064] (3) Cover the special extrusion die installed on the extruding device outside the connector 1, and the extruding device adopts existing conventional equipment;

[0065] (4) Use extrusion ...

Embodiment 4

[0067] see Figure 6-Figure 8 , this embodiment is the first specific implementation of the steel bar connection joint obtained by applying the connection method described in Example 3 of the present invention, and the joint includes the connection of steel bar A5 and steel bar B6 that are close together in parallel to form overlapping overlapping sections end and the connecting piece 1 wrapped on the connecting end of the steel bar A5 and the steel bar B6, the inner surface of the connecting piece 1 and the convex rib on the surface of the steel bar tightly bite together, and the contact surface between the steel bar A5 and the steel bar B6 is pressed against each other Tight and bite.

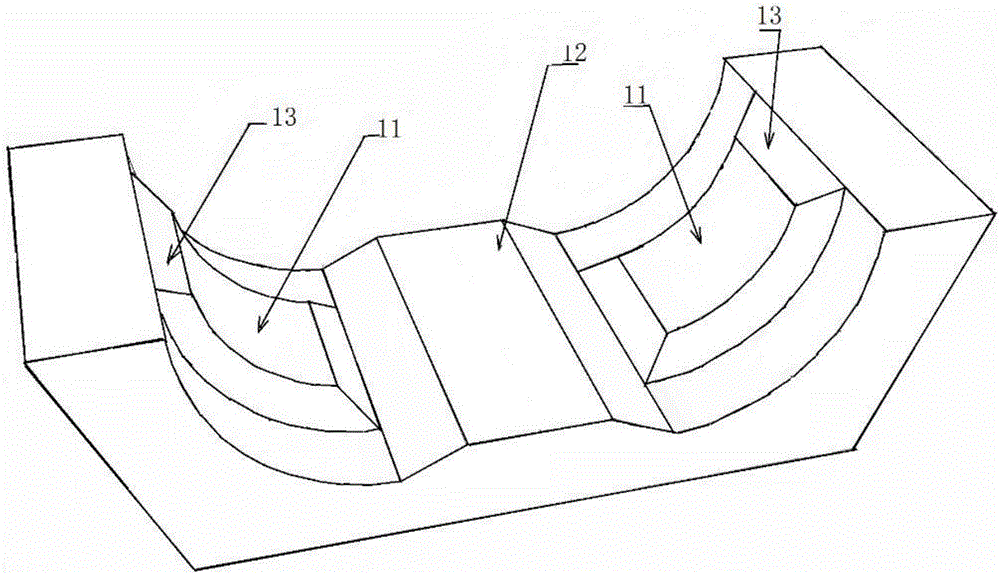

[0068] The outer surface of the connecting piece 1 is provided with circumferential grooves 7 , and the circumferential grooves 7 are in multiple groups, distributed along the axial direction of the connecting piece 1 , and surround the whole connecting piece 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com