Shock-proof prefabricated steel tube shear wall mixed structural building

A hybrid structure and shear wall technology, applied in building structures, buildings, building components, etc., can solve the problems of unreasonable overall assembly and connection structure, inconvenient component operation, complex formwork system, etc., to shorten the construction period, The effect of high component prefabrication rate and excellent quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

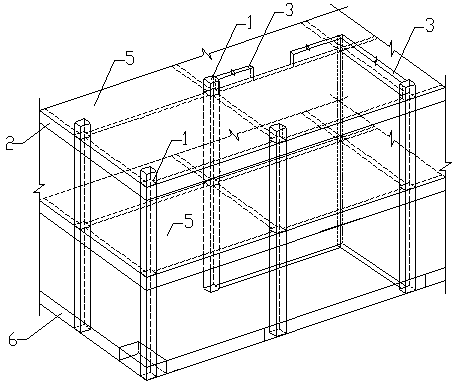

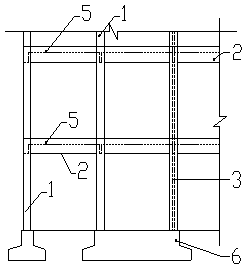

[0052] Such as Figure 1-Figure 23 As shown, the building of the present invention mainly includes: steel column 1, steel beam 2, shear wall 3, laminated floor slab 5, foundation 6, foundation 6 is connected with steel column 1, foundation 6 is connected with shear wall 3, steel column 1 is connected to steel beam 2, steel beam 2 is connected to laminated floor 5, steel beam 2 is connected to shear wall 3, shear wall 3 is connected to laminated floor 5, and shear wall 3 is connected vertically to the upper and lower sections. The upper single shear wall 3 is combined and connected to form a shear wall cylinder, the prefabricated stair tread plate 51 is connected with the upper support beam 52 and the lower support beam 53, and the self-supporting masonry filling wall 65 is connected with the main structural parts.

[0053] The specific implementation of each structural part and its connection:

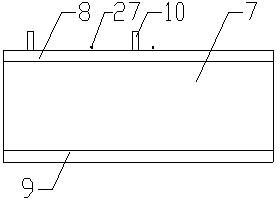

[0054] Steel beam 2, see attached image 3 , steel beam 2 is divided into two cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com