Butt joint connecting structure of precast concrete components

A technology of prefabricated concrete and prefabricated components, which is applied in the direction of building construction and construction, and can solve problems such as the difficulty in ensuring the minimum clear distance of the sleeve, the long time to form the bearing capacity at the connection, and the difficulty in protecting the longitudinal reinforcement to be connected. , to achieve the sustainable development of social economy, the thickness of the protective layer is easy to guarantee, and the effect of improving the level of building industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

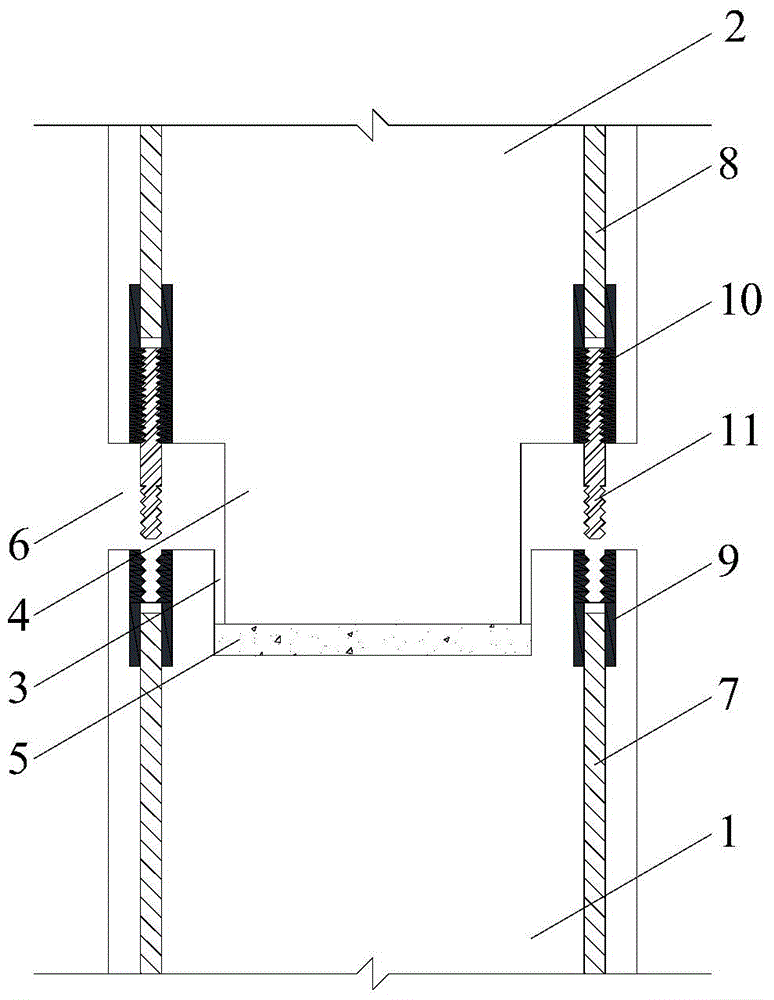

Embodiment 1

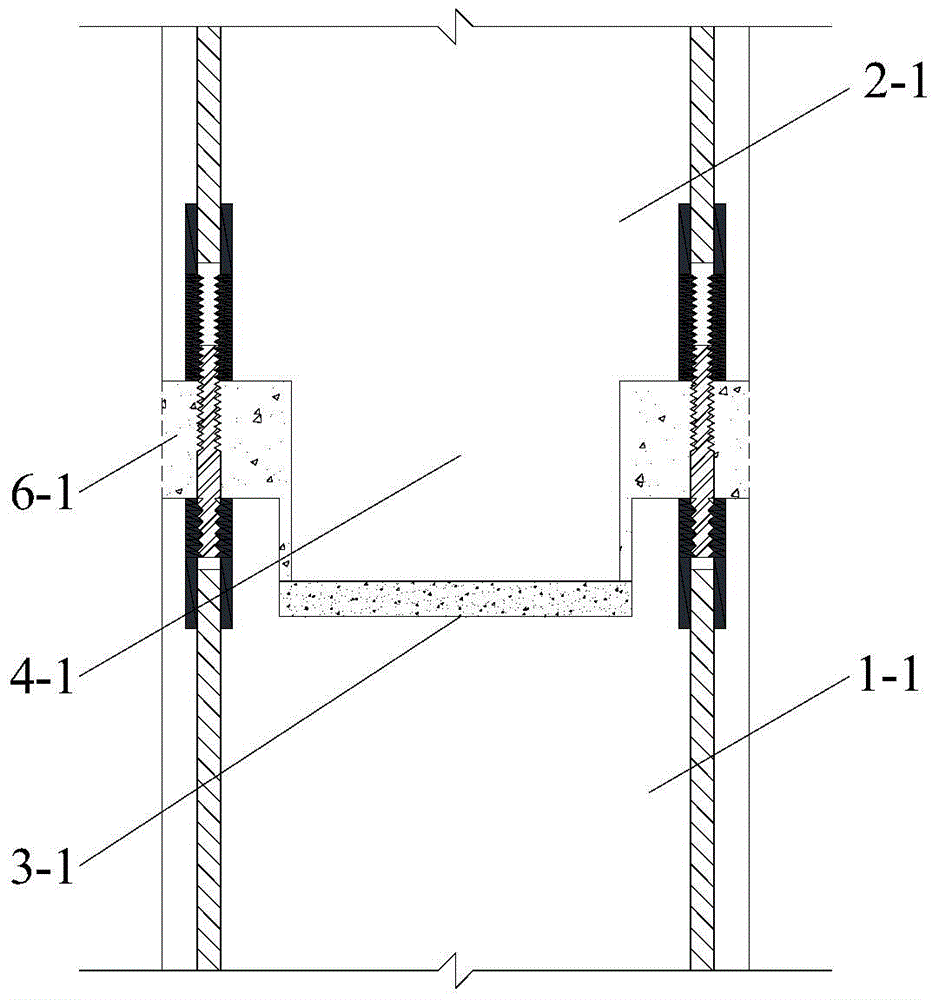

[0027] Such as figure 2 As shown, it is a non-floor position connection of columns, the connection objects are prefabricated column one 1-1 and prefabricated column two 2-1, the connection end of prefabricated column one 1-1 is provided with a pit 3-1, and the prefabricated column The connecting end of the second 2-1 is provided with a protrusion 4-1, the protrusion 4-1 is adapted to the transverse shape and size of the pit 3-1, and the protrusion 4-1 is adapted to the longitudinal shape of the pit 3-1 Matching, the longitudinal length of the protrusion 4-1 is greater than the longitudinal depth of the pit 3-1; the longitudinal ribs to be connected of the prefabricated column 1-1 and the prefabricated column 2 2-1 are connected with their respective connecting sleeves by cold extrusion , the corresponding two connecting sleeves are threadedly connected through a connecting screw; after the protrusion 4-1 is inserted into the pit 3-1, it is tightly connected through the cushio...

Embodiment 2

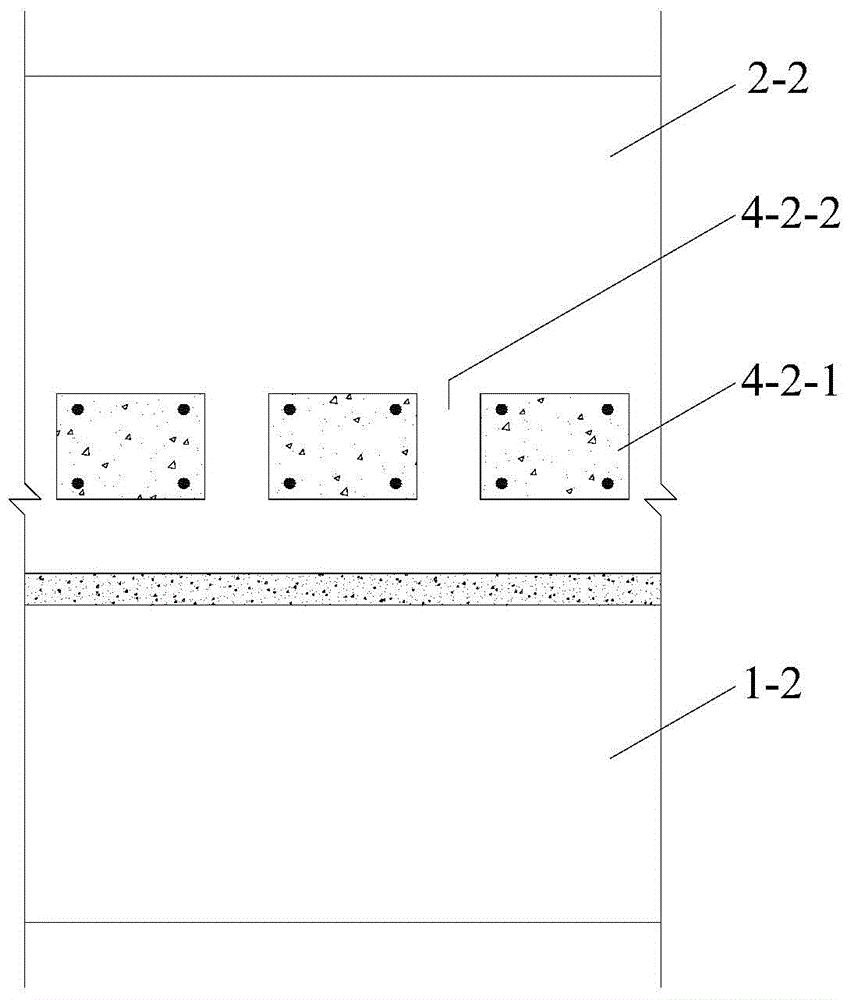

[0030] Such as image 3 , Figure 4 and Figure 5As shown, it is a wall-to-floor position connection, the connection objects are prefabricated shear wall 1-2 and prefabricated shear wall 2 2-2, and the connection end of prefabricated shear wall 1-2 is provided with a groove 3 -2, the connection end of the prefabricated shear wall 2-2 is provided with a protrusion 4-2, the protrusion 4-2 matches the transverse shape and size of the groove 3-2, and the protrusion 4-2 and the groove 3 -2 is compatible with the longitudinal shape, and the longitudinal length of the protrusion 4-2 is greater than the longitudinal depth of the groove 3-2; the longitudinal reinforcements to be connected of the prefabricated shear wall 1-2 and the prefabricated shear wall 2-2 are both Connect with their respective connecting sleeves through cold extrusion, and the corresponding two connecting sleeves are threaded through a connecting screw; after the protrusion 4-2 is inserted into the groove 3-2, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com