An assembly-cast-in-place dense column structure for residential buildings with shear wall system

A technology of residential buildings and shear walls, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of poor integrity and earthquake resistance, low degree of industrialization, and restrictions on prefabricated structures, so as to improve the prefabrication rate and overcome Defects, the effect of realizing industrialized operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

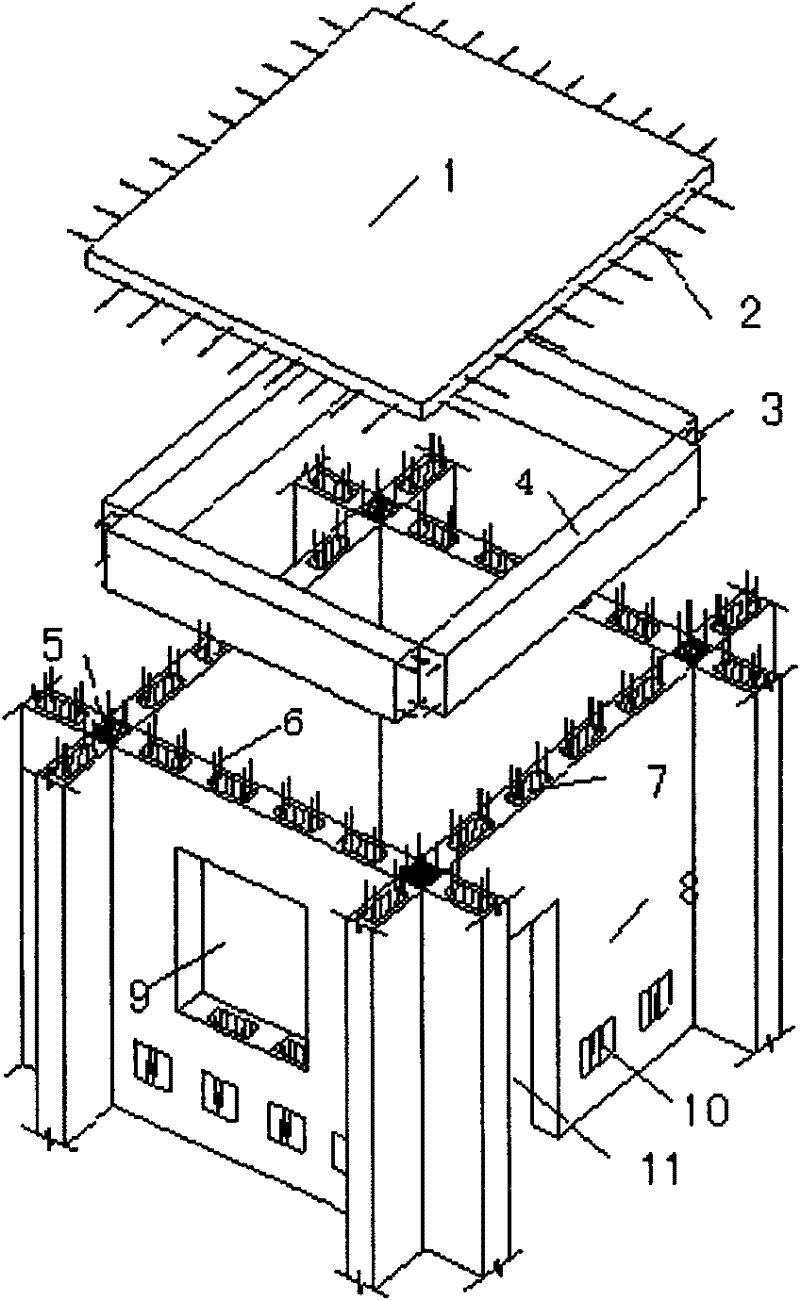

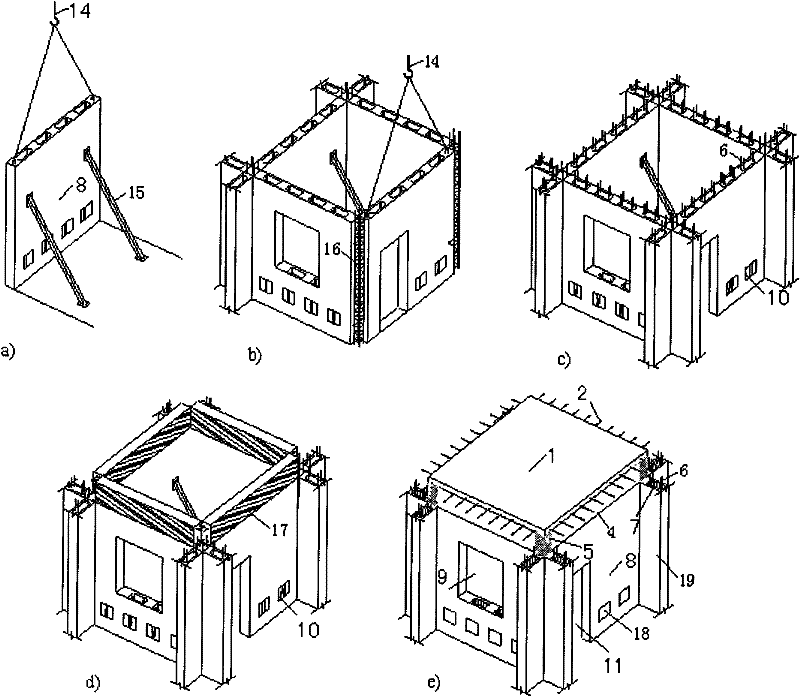

[0017] figure 1 As shown, the present invention is used for the assembly-cast-in-place dense column structure of the multi-storey residential building of the shear wall system. The slab consists of 1. The cavity diaphragm thickness of the prefabricated building hollow wall form 8 is 30mm. The prefabricated building hollow wall formwork 8 is installed by a crane, temporarily fixed after correction, and the cast-in-place dense columns 7, cast-in-place corner columns 5, cast-in-place beams 4 and floor 1 are connected with steel bars and formwork supports, and then concrete is poured. Form the overall structure of dense columns.

[0018] In order to form the assembly-cast-in-place dense column structure, the technical scheme adopted is:

[0019] (1) Factory prefabricated building hollow wall formwork

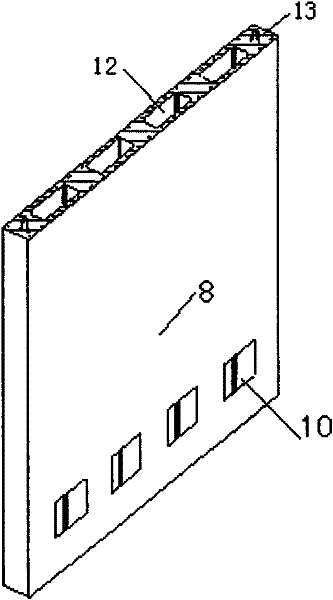

[0020] figure 2 As shown, the prefabricated building hollow wall formwork 8 is a modularized permanent formwork, its area is equivalent to a single shear wall, its height and ...

Embodiment 2

[0030] The present invention is used in the assembly-cast-in-place dense column structure of a small high-rise residential building with a shear wall system, including a prefabricated building hollow wall form 8, a cast-in-place dense column 7, a cast-in-place corner column 5 and a cast-in-place beam 4, and a cast-in-place floor slab 1 composition. The cavity diaphragm thickness of the prefabricated building hollow wall form 8 is 60mm. The prefabricated building hollow wall formwork 8 is installed by a crane, temporarily fixed after correction, and the cast-in-place dense columns 7, cast-in-place corner columns 5, cast-in-place beams 4 and floor 1 are connected with steel bars and formwork supports, and then concrete is poured. Form the overall structure of dense columns.

[0031] The concrete construction process of embodiment 2 is the same as embodiment 1.

[0032] By adopting the assembly-cast-in-place dense column structure, the industrialized construction of the shear w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com