Prefabricated steel joint concrete slab-column structure and hoisting method thereof

A concrete column and prefabricated assembly technology, applied to floors, building components, building structures, etc., can solve problems such as low construction efficiency, difficult assembly design and construction, and limited lateral resistance of slab-column structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

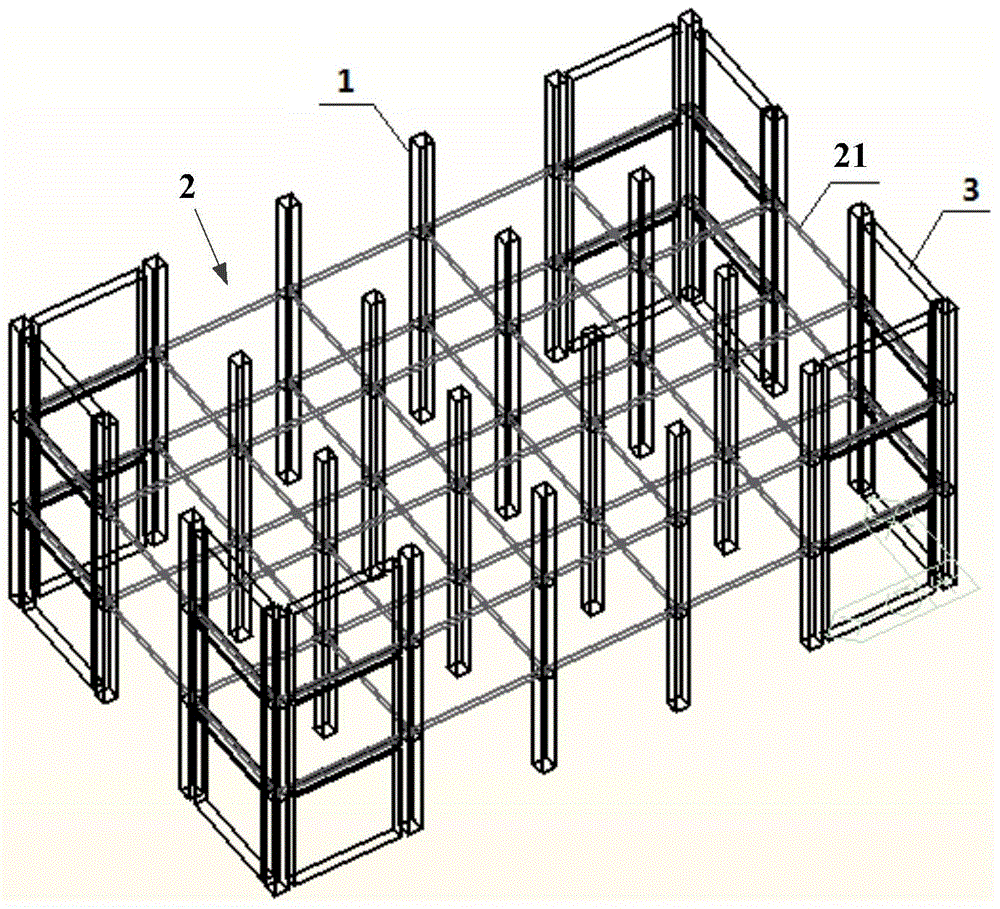

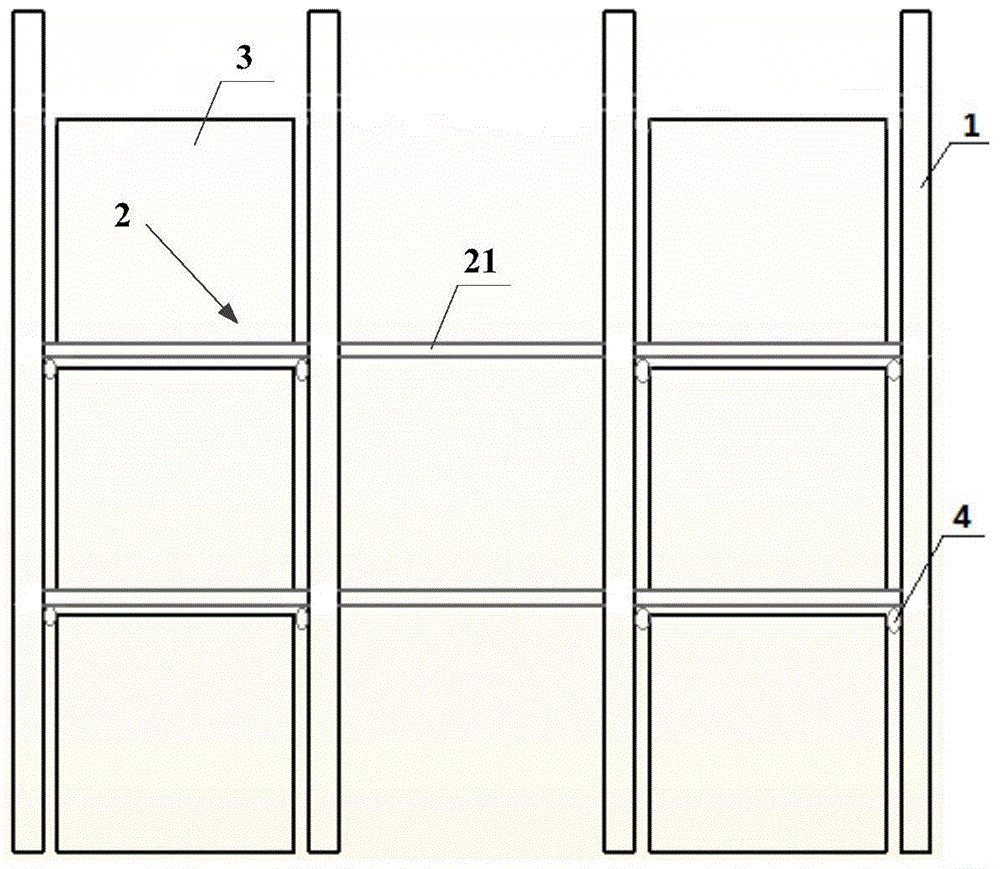

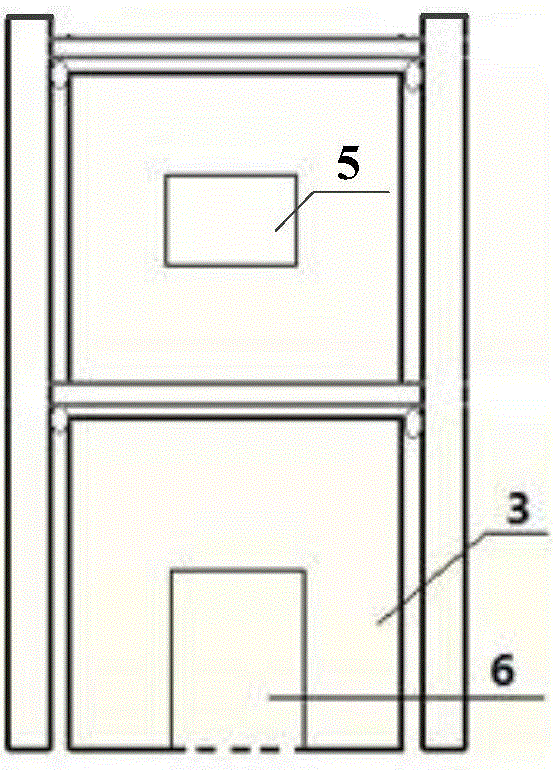

[0049] Such as Figure 1~2 As shown, the embodiment of the present invention provides a prefabricated steel node concrete slab-column structure, including:

[0050] Concrete slab 2, comprising one or more concrete slabs 21, the concrete slab 2 bears vertical loads while providing sufficient horizontal stiffness;

[0051] The multi-section concrete column 1, the concrete column 1 bears the vertical load transmitted by the concrete floor 2, and the bottom end of any section of the concrete column 1 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com