Inner binding outer cramping method architecture structural crack comprehensive processing method

A technology for building structure and comprehensive treatment, applied in building components, building structures, buildings, etc., can solve problems such as cracking, difficult to completely deal with cracks, and component cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

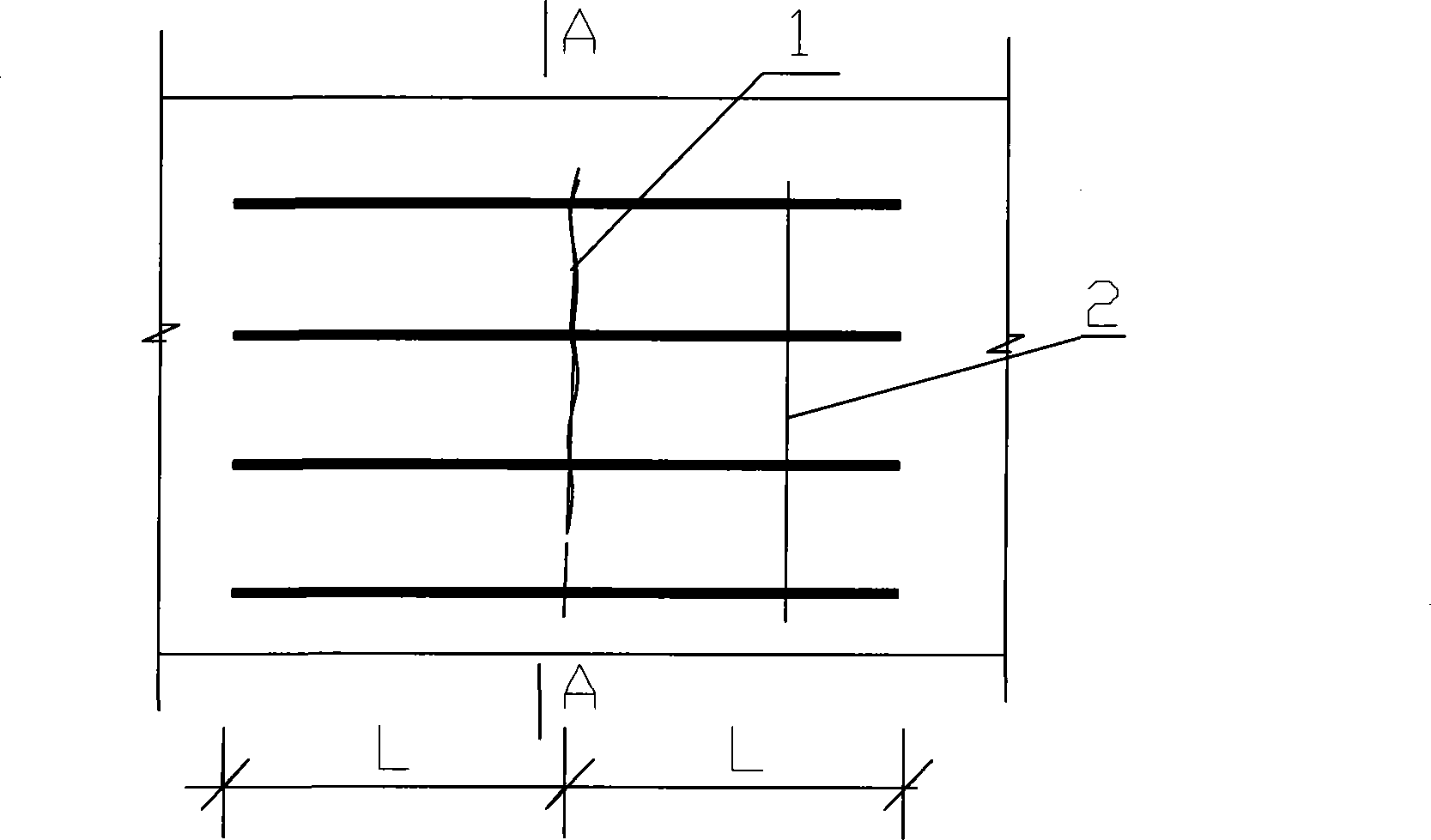

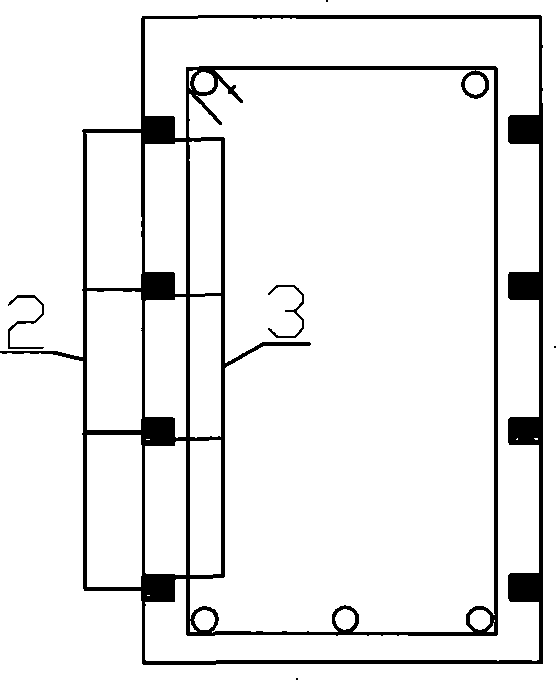

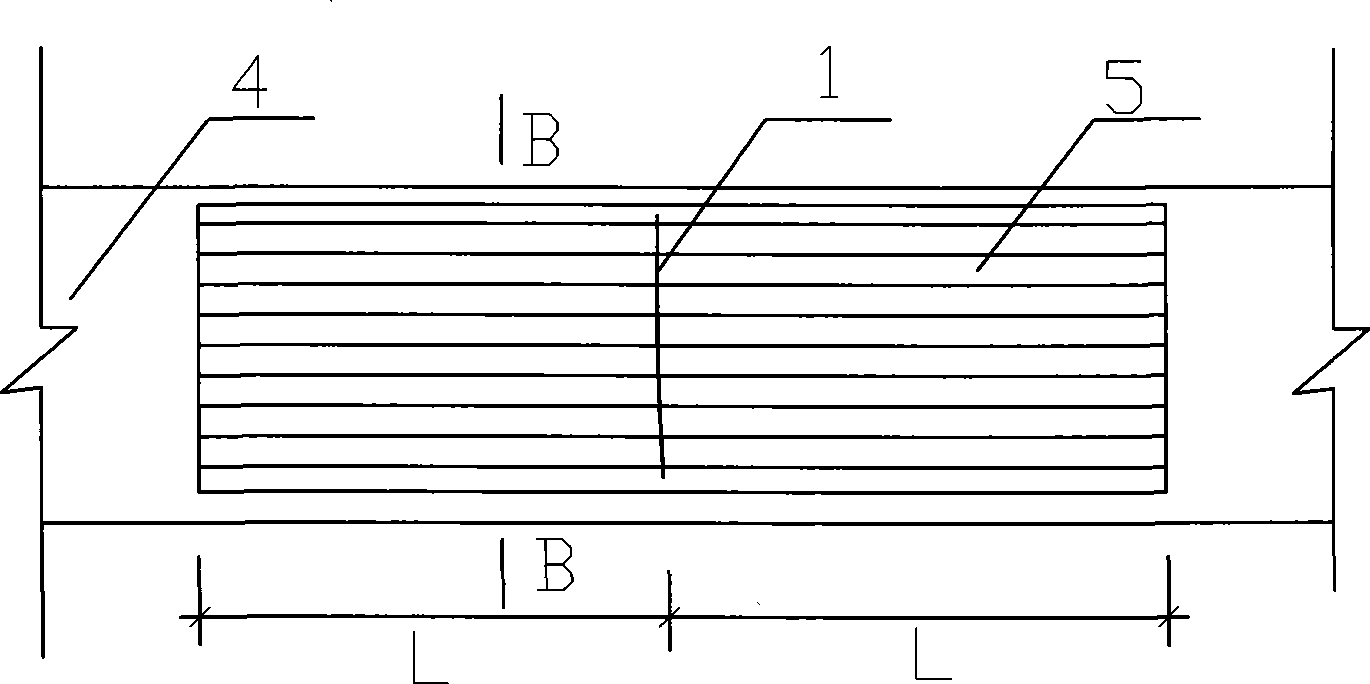

[0033] Such as Figure 1-8 After the internal adhesive material shown is cured, fiber-reinforced composite materials (Fibre-Reinforced Polymers, referred to as FRP, including carbon fiber CarbonFibre-Reinforced Polymers, referred to as CFRP, aramid fiber AramidFibre-Reinforced Polymers, referred to as AFRP and glass fiber Glass Fiber-Reinforced Polymers, GFRP for short) for surface suture --- outer curium.

[0034] (1) Surface-bonded fiber-reinforced composites (FRP) ( image 3 , Figure 4 , Figure 7 , Figure 8 )

[0035] Surface-adhesive FRP is suitable for the reinforcement of concrete and masonry, mainly including base treatment, priming, leveling, pasting and other processes:

[0036] Grass-roots treatment: Pop up the smoothing control line at the pasting position. The length direction of the smoothing control range should be increased by 50mm from each side of the pasted range, and the width direction should be increased by 30mm from each side of the pasted range. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com