Double-row sheet pile decompression self-unloading method and double-row pile structure thereof

A sheet pile structure and self-unloading technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of sheet pile structure deformation, affecting the overall service performance of double-row steel sheet pile structures, etc., to reduce soil Body stress state, simple structure, and the effect of improving integrity and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

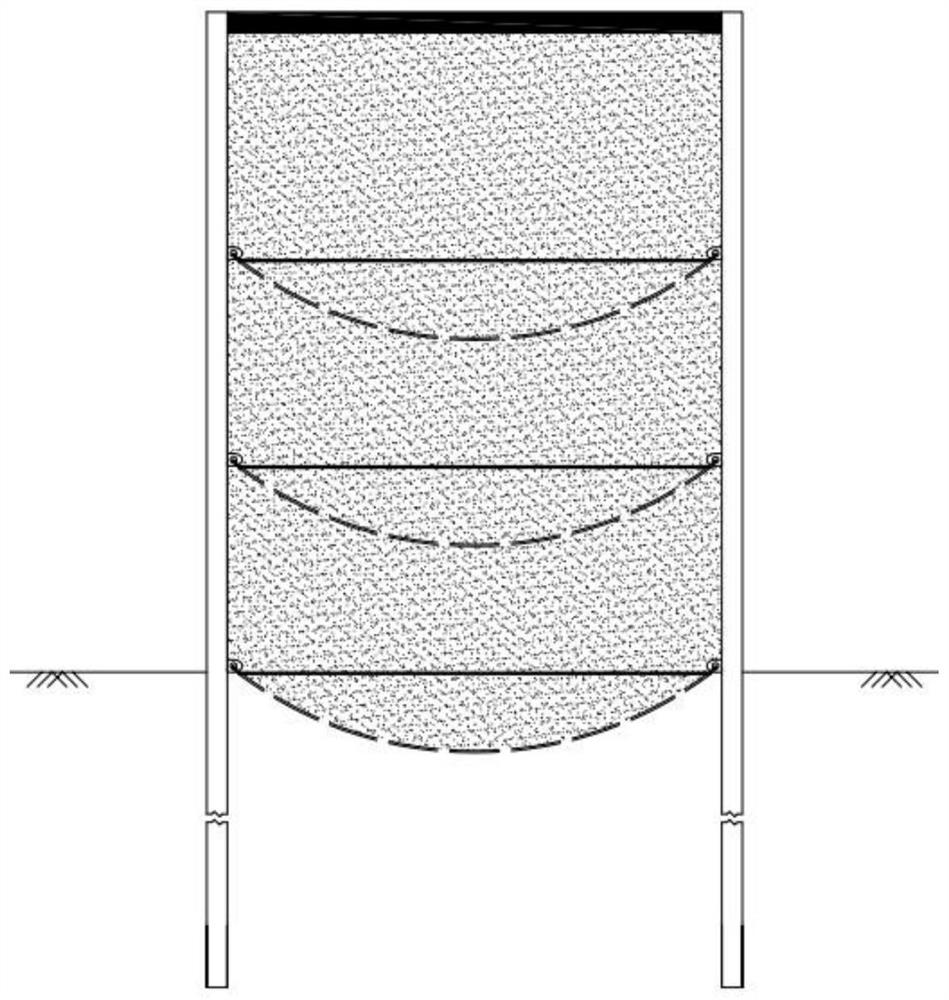

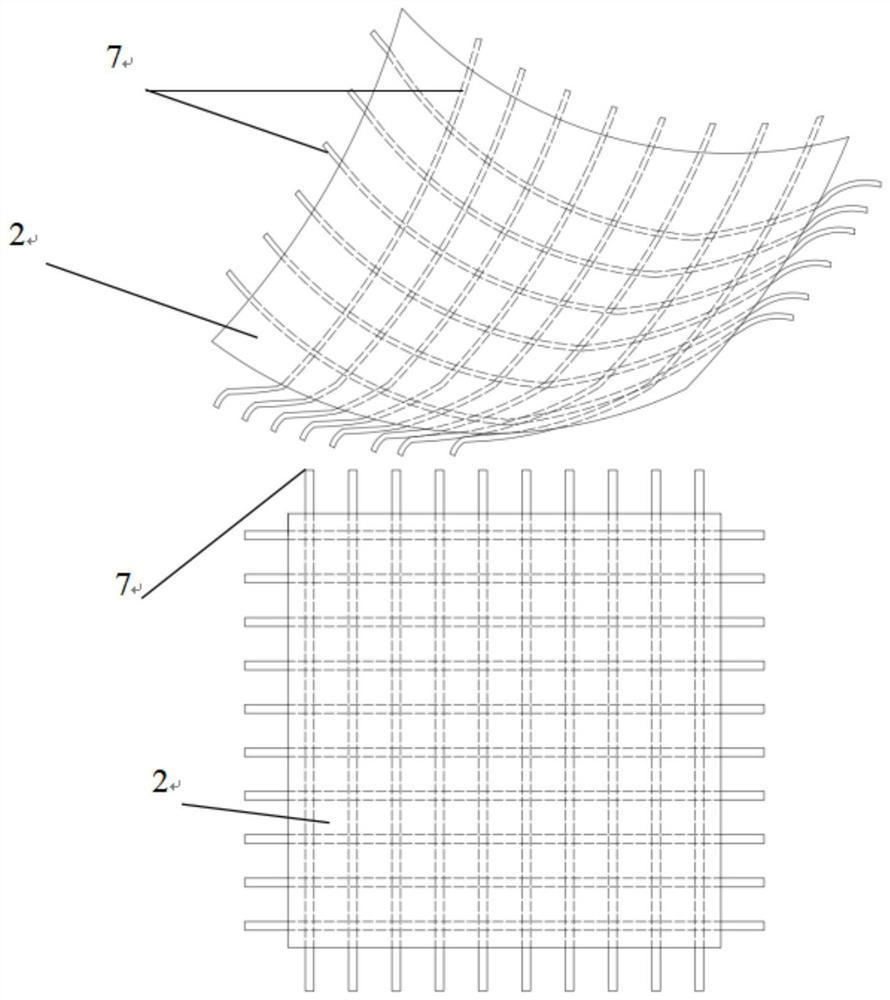

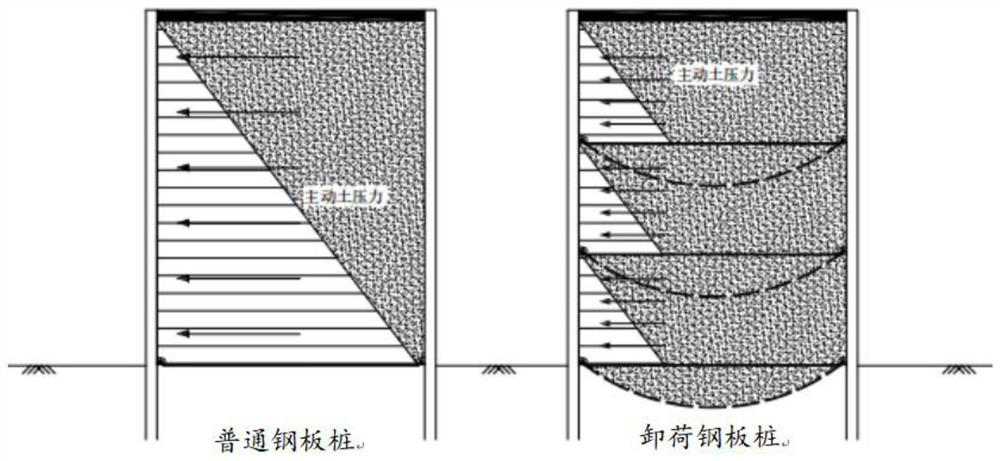

[0035] Combine below Figure 1-8 The specific implementation will be described in further detail. A decompression and self-unloading method for double-row sheet piles in this implementation case, the method includes the design and installation process of self-unloading double-row sheet piles and the optimal process of mechanical calculation of self-unloading double-row sheet piles;

[0036] Step 1, the design and installation process of self-unloading double-row sheet piles, reasonable construction of double-sheet pile structures in the area to be constructed to form a cofferdam;

[0037] Step 2, the optimal process of mechanical calculation of self-unloading double-row sheet piles, computational mechanics calculations are performed on the self-unloading double-row sheet pile structure to obtain unloading geotextiles with different layers 2 Double-row slabs under the action of unloading force pile load.

[0038] Step 1 in this implementation case is as follows image 3As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com